Constant-velocity joint and image forming device

A speed coupling and coupling technology, which are applied in the field of image forming devices, can solve the problems of large-scale constant speed coupling, increase in the number of parts, increase in cost, etc., so as to improve the degree of freedom of design and reduce the number of parts. , The effect of low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

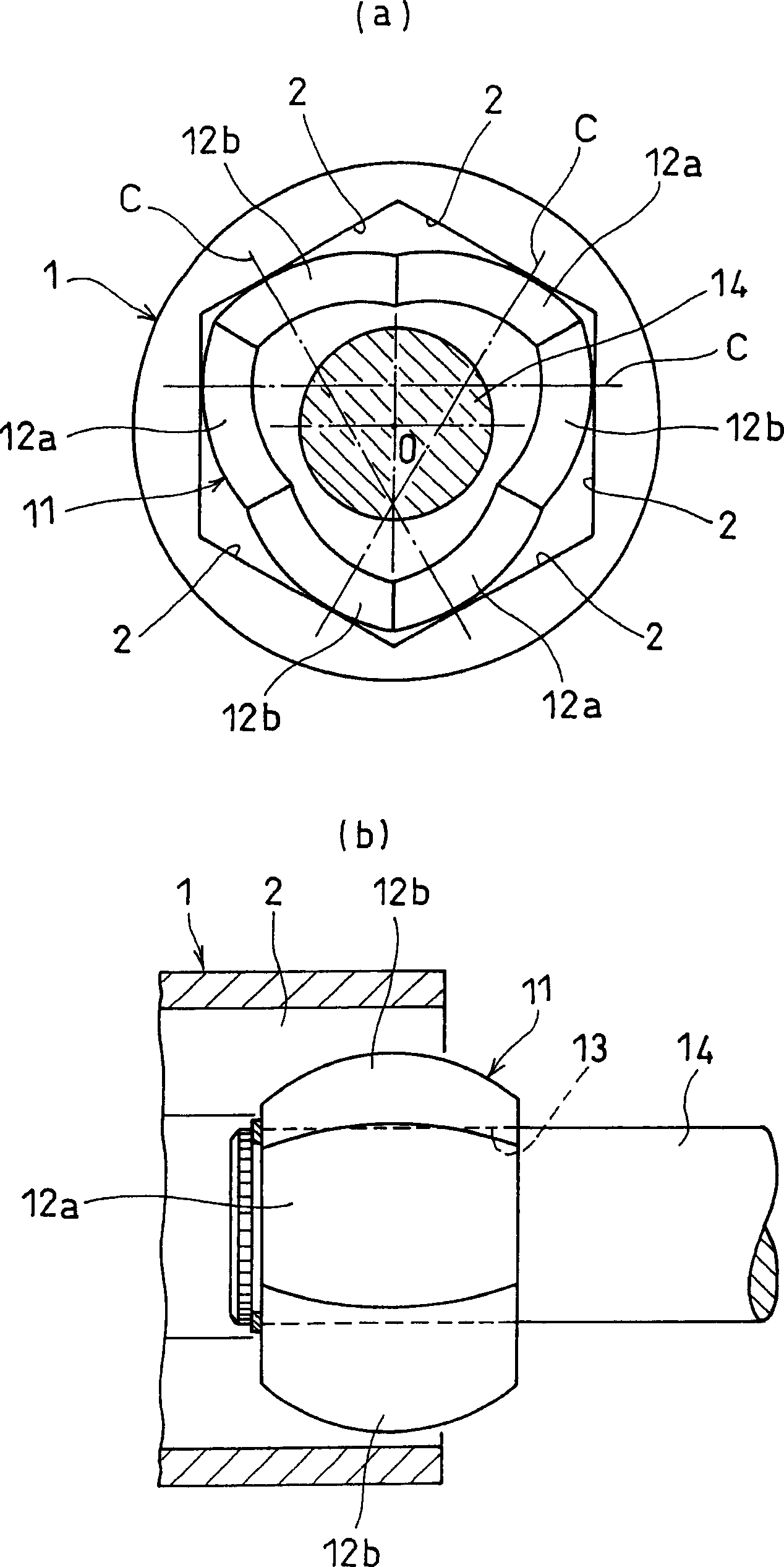

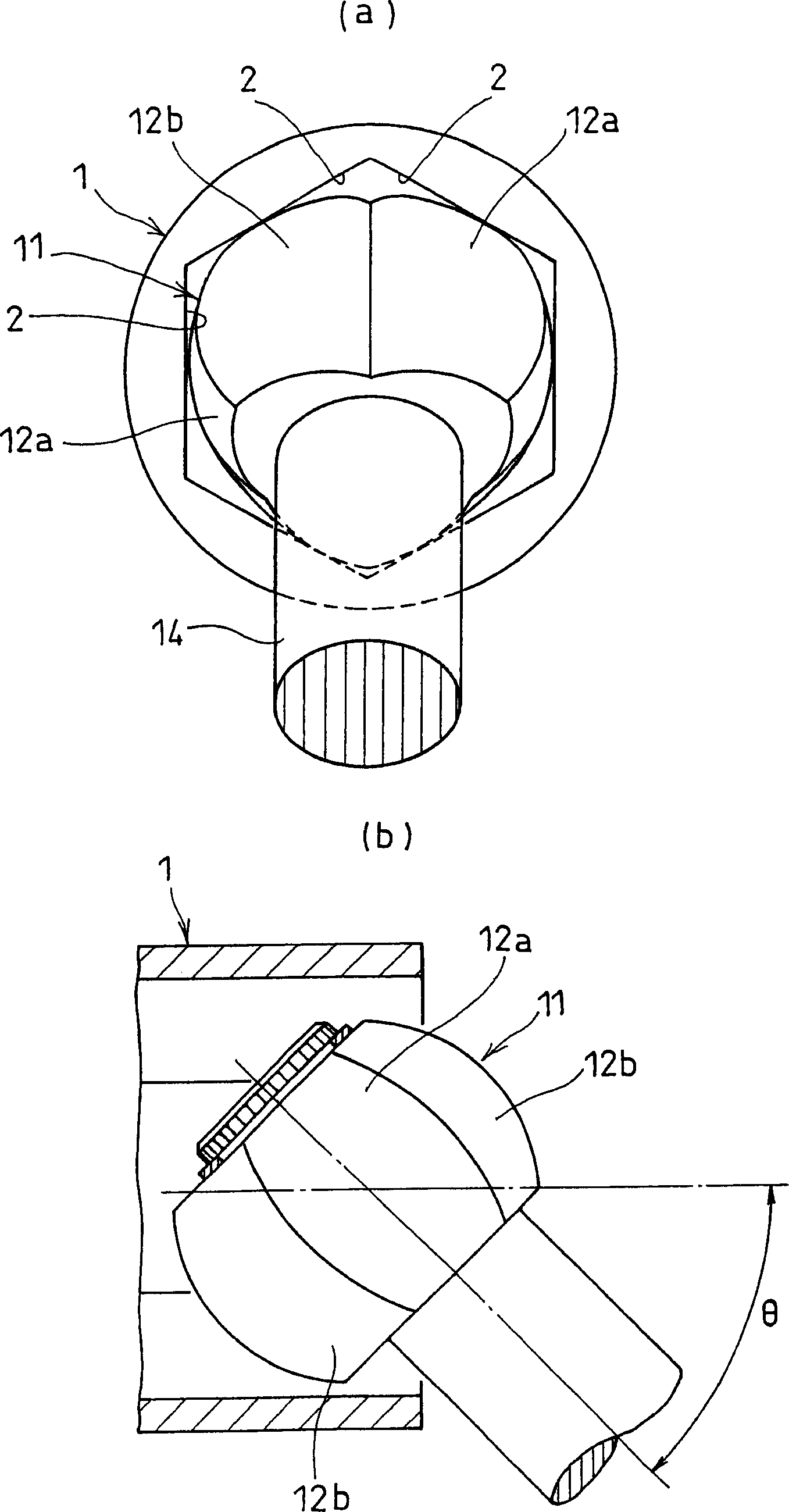

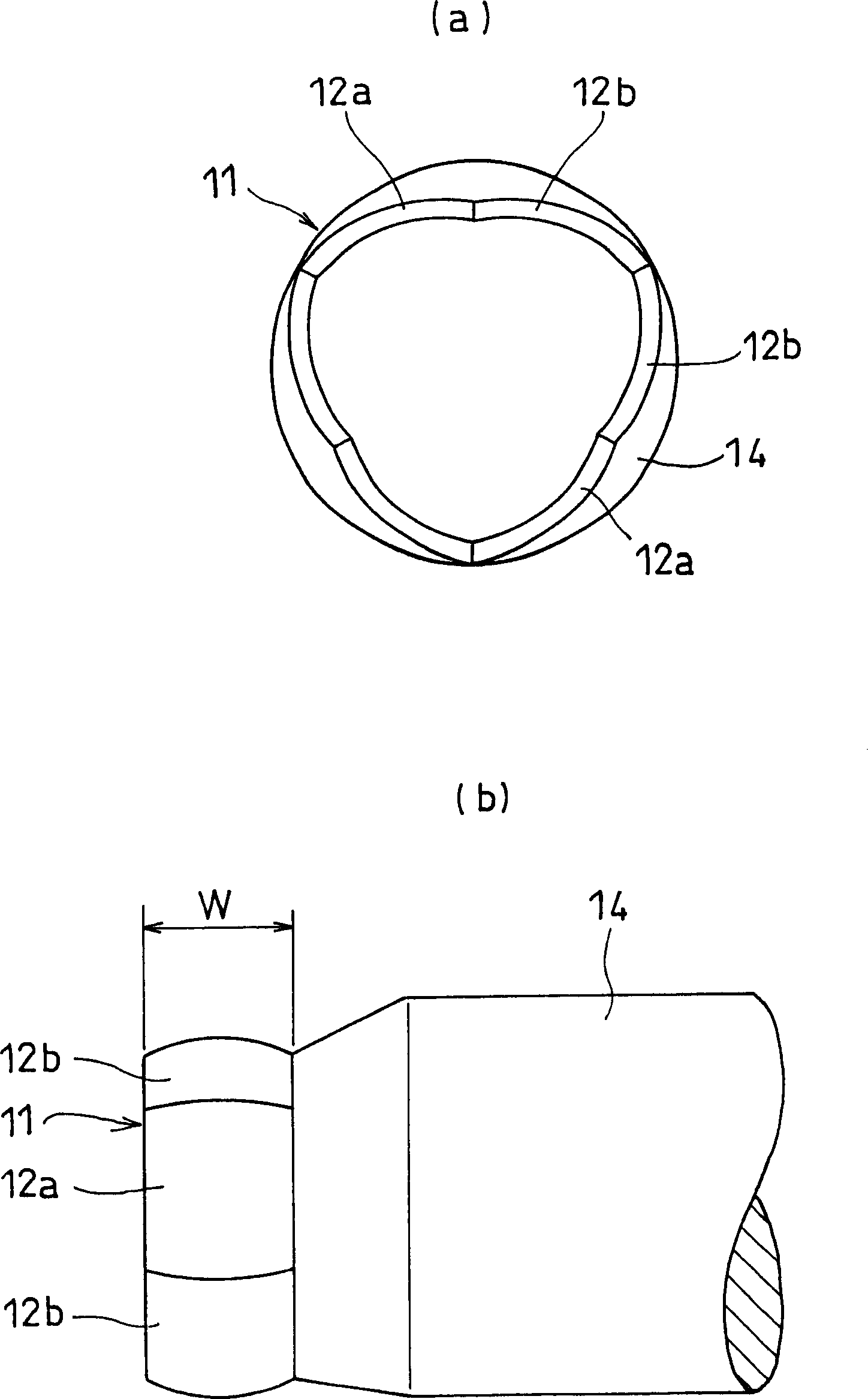

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Such as figure 1 As shown in (a) and (b), the constant velocity coupling is composed of an outer wheel 1 and a pivot member 11. The outer wheel 1 has a regular hexagonal hollow hole surrounded by six flat surfaces 2 parallel to the axis. The shaft member 11 is assembled in this hollow hole.

[0040] On the outer peripheral surface of the pivot member 11, three first spherical surfaces 12a and three second spherical surfaces 12b that are in contact with the flat surface 2 are alternately formed along the circumferential direction.

[0041] The first spherical surface 12 a is in contact with the flat surface 2 at a position deviated from the central position of the flat surface 2 in the circumferential direction to one side in the circumferential direction (clockwise in the figure). In addition, the second spherical surface 12 b is in contact with the flat surface 2 at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com