Reib material

A friction material and organic material technology, applied in the field of friction materials, can solve the problems of inability to fully control the degree of compression deformation, increase in the degree of high temperature deformation, and limit the degree of compression deformation, and achieve excellent speed expansion ability, small change, The effect of optimizing the degree of compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Exemplary embodiments of the present invention will be described with reference to the accompanying drawings.

[0038] During the fabrication of conventional C / C composites, the problem lies in controlling the frictional properties and degree of compression set of the mixed metals as well as the inorganic materials. The reason is that because the composite material is repeatedly baked at high temperature (2000°C or higher), the metal and organic material may melt and flow out, so it is easy to decompose and sublimate, and they cannot be mixed.

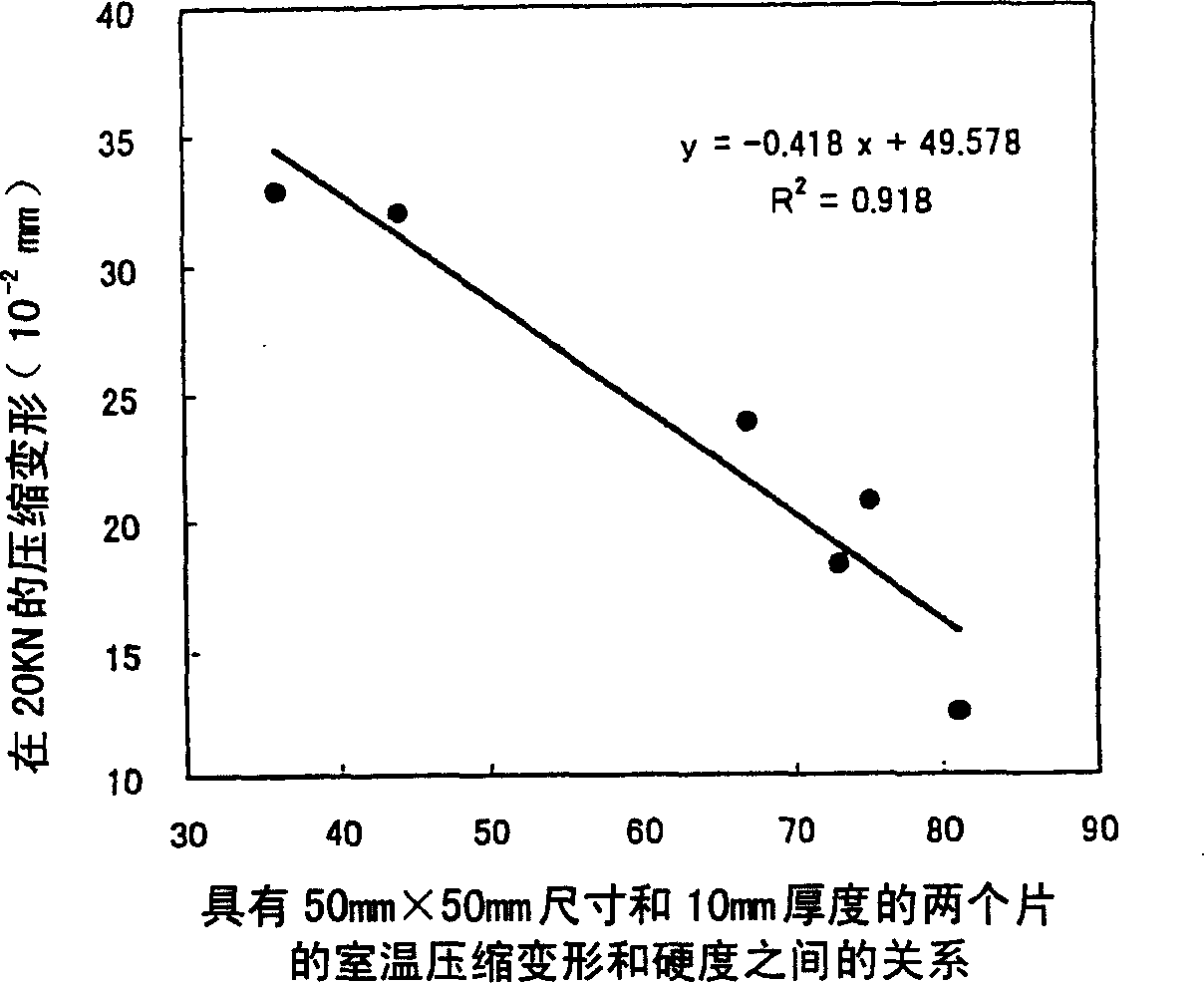

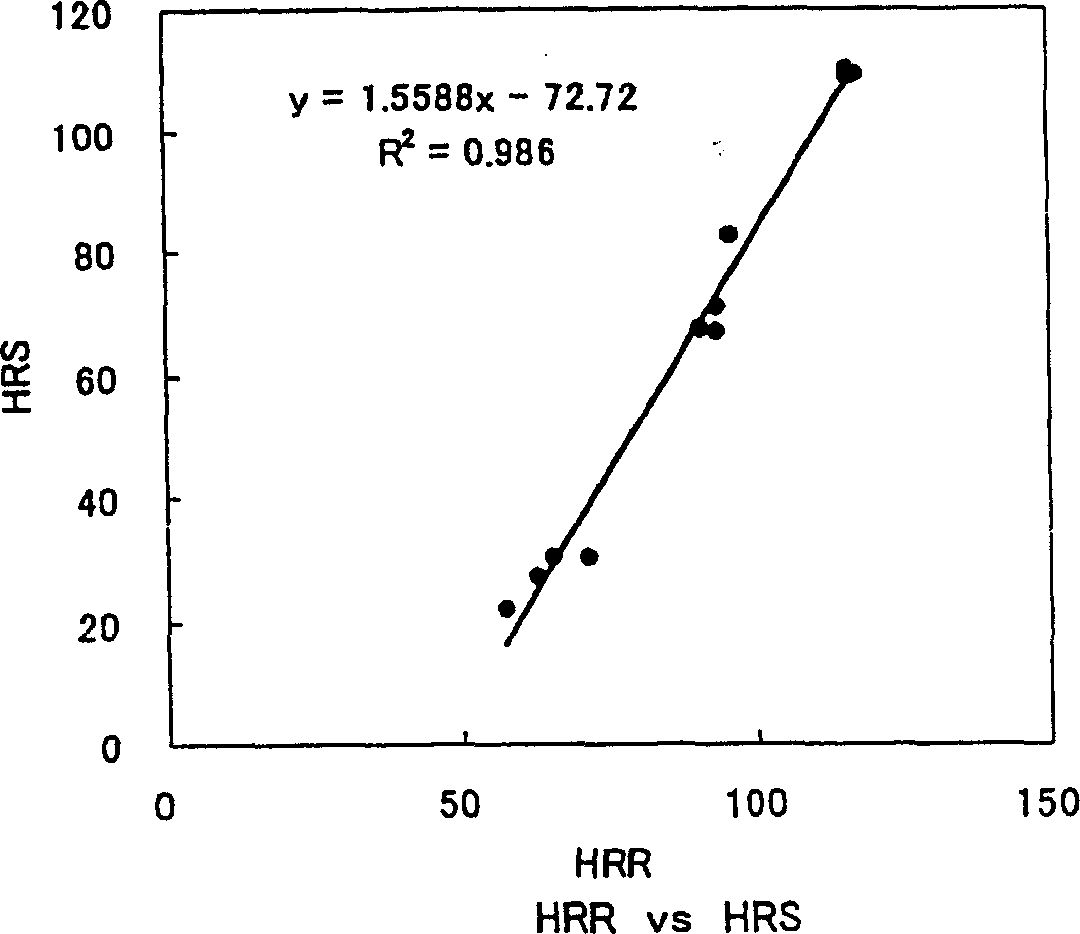

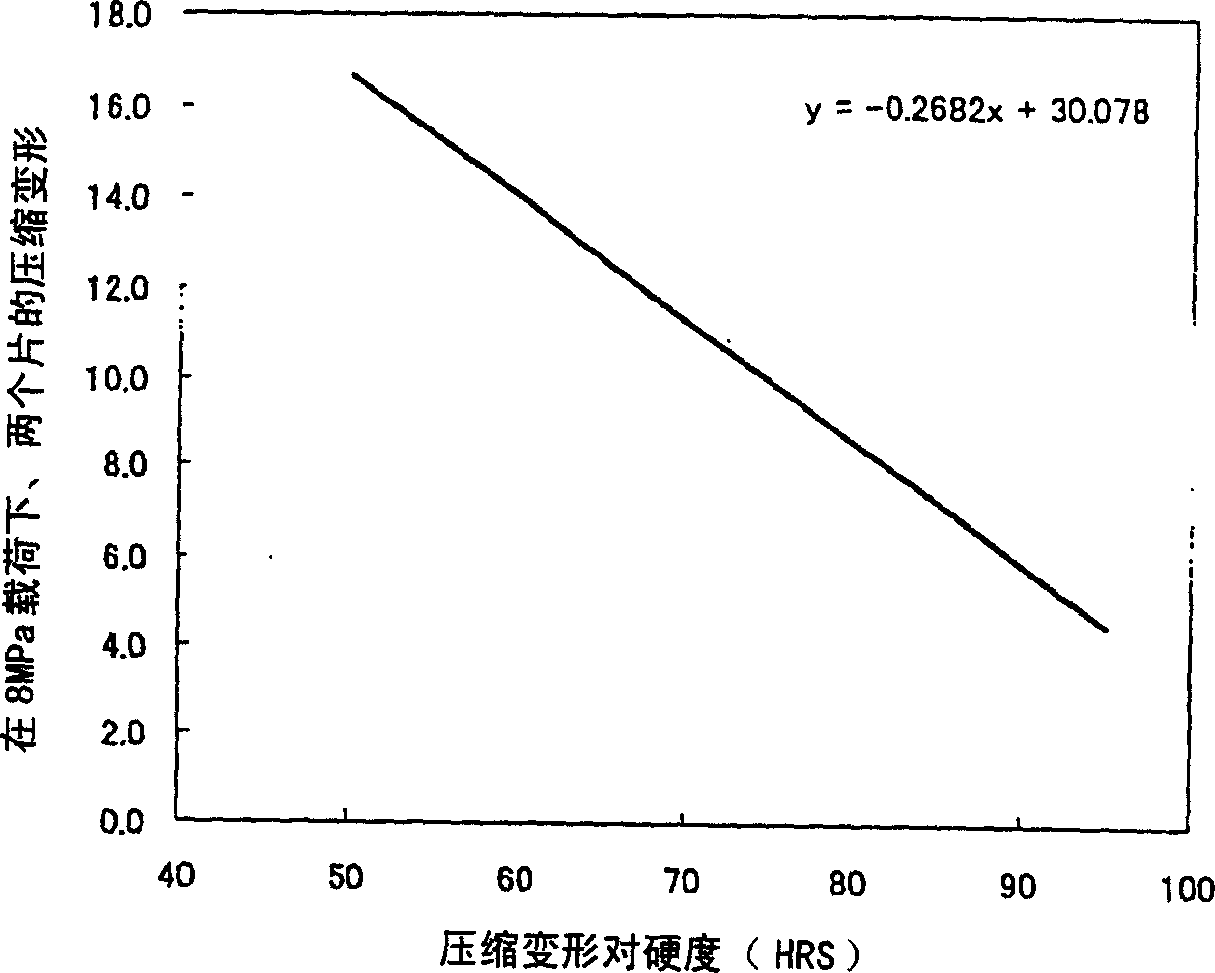

[0039] In order to solve this problem, methods of carbonization and mixing at low temperatures have been investigated previously (for example, Patent Document 5, Patent Document 6). In the examples of these references, hardness (with a Rockwell hardness scale: HRS) is measured as a proxy for the degree of compression set. However, among these, the material cannot have a satisfactory degree of compression deformation harder than c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com