Linear actuator with fast releaser

A linear actuator and release technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of limited use range and complicated mechanism design, and achieve the effect of increasing safety and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

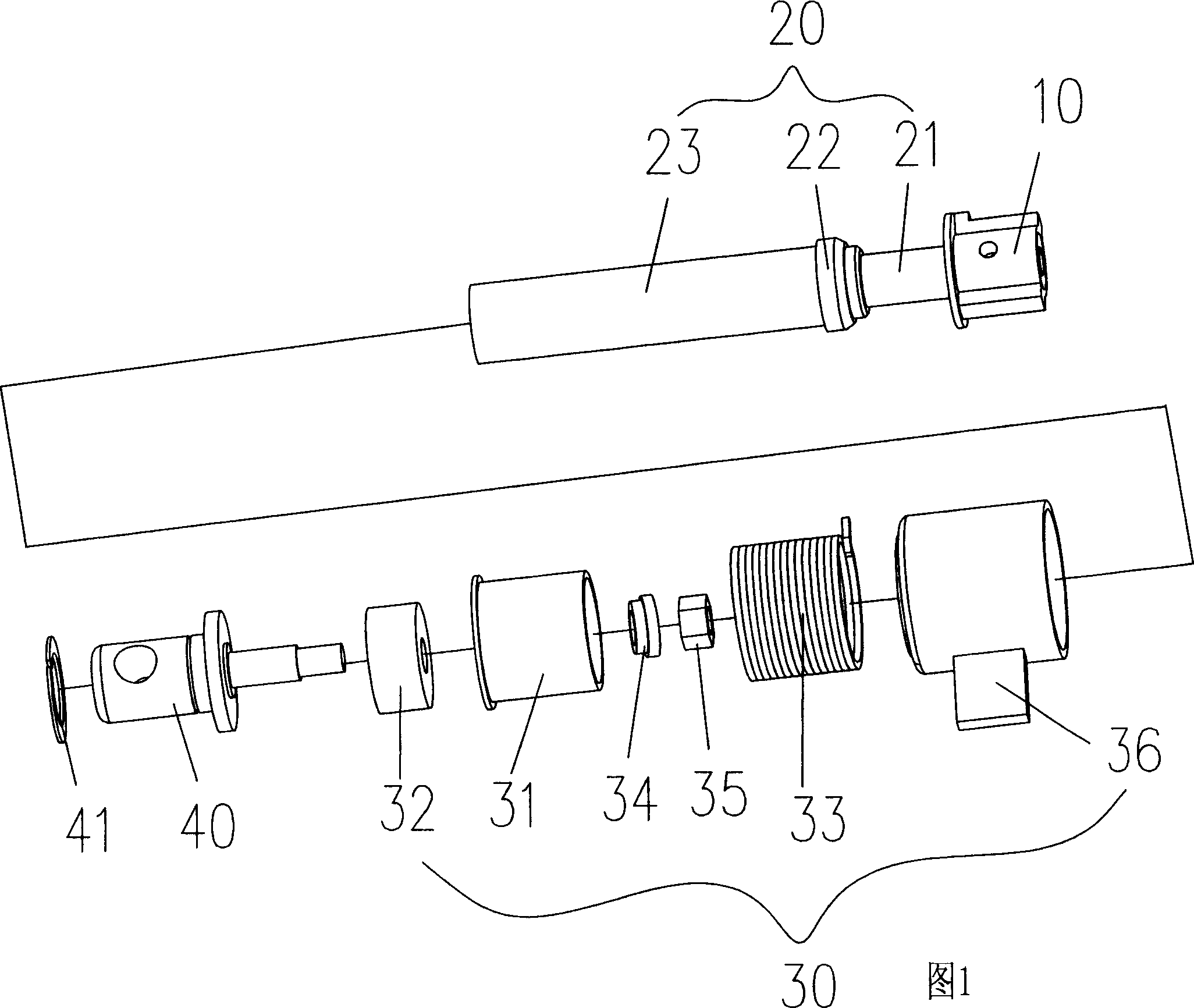

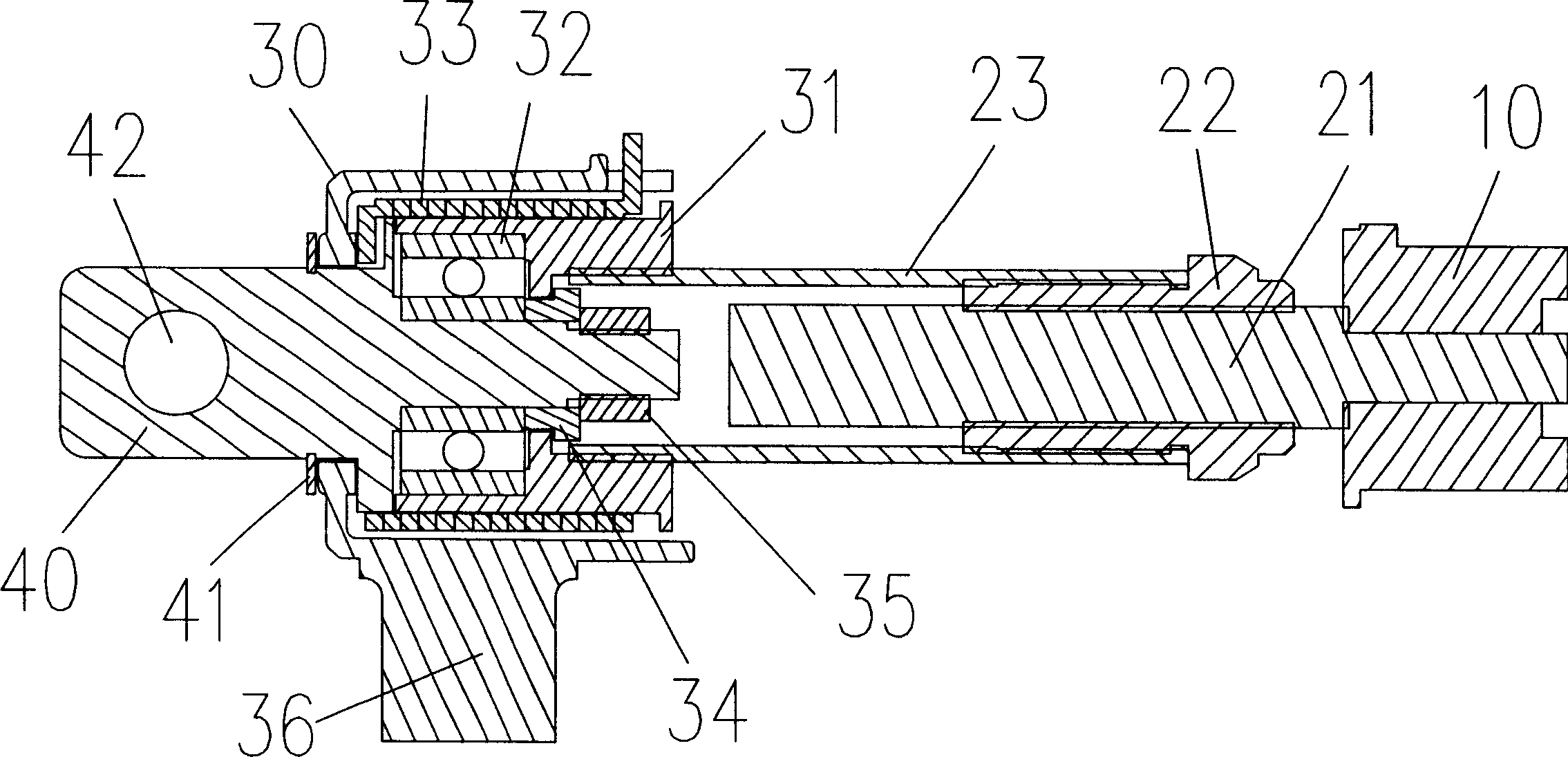

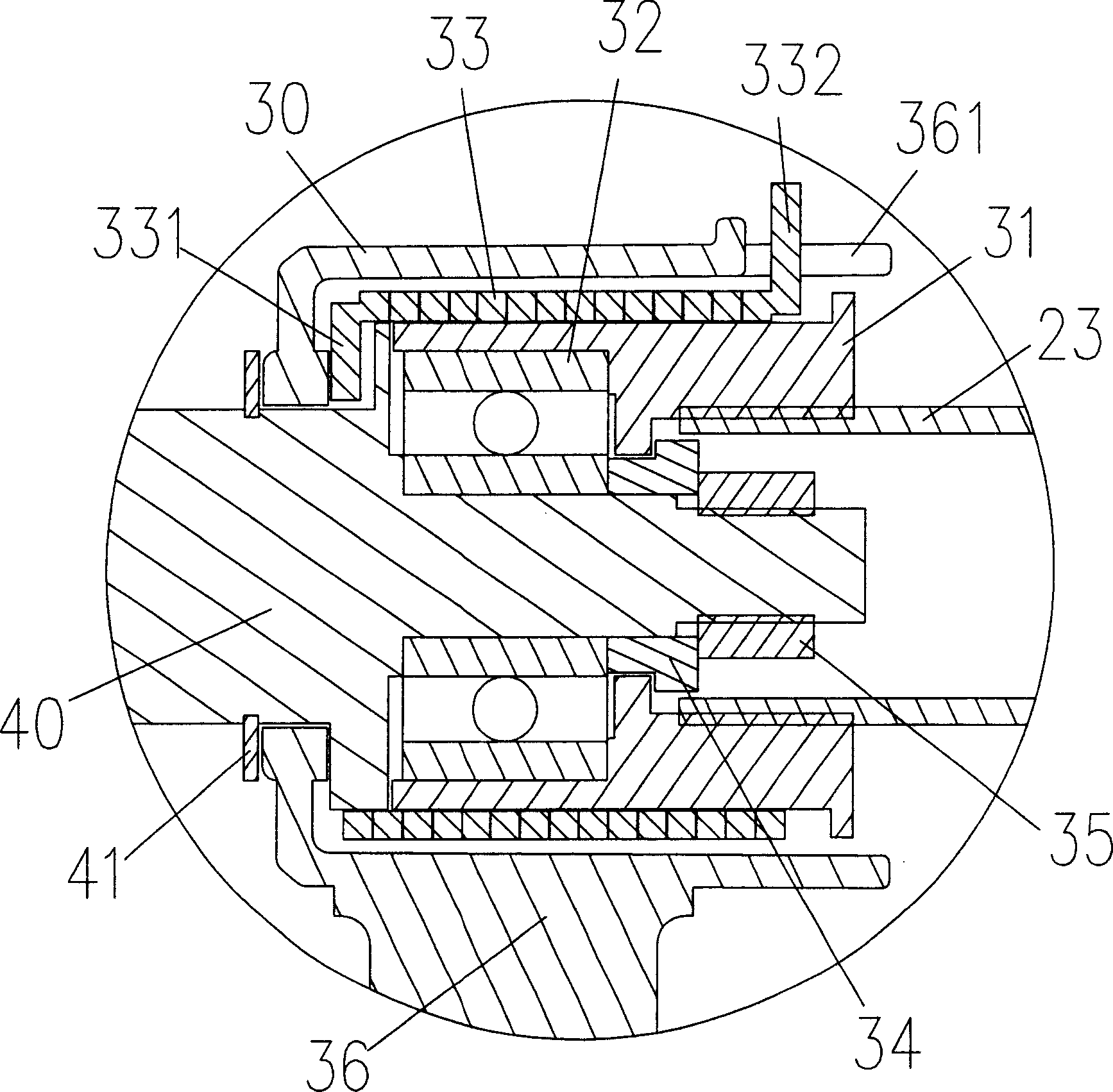

[0028] Fig. 1 is a three-dimensional exploded view of a linear actuator with a quick release mechanism in the present invention; wherein the power device 10 is a power source that outputs rotational torque, and transmits the torque from the motor to a transmission device 20, and the transmission device 20 includes a screw shaft 21. The nut 22 and the inner tube 23, and there is a quick release device 30 between the transmission device 20 and the load joint 40; the screw shaft 21 is connected to the power device 10 to transmit power, and the nut 22 fits on the screw shaft 21 to The rotational torque is converted into linear motion, and the inner tube 23 is fixed on the nut 22 to move with the nut 22. The rear end of the inner tube 23 is fixed on the inner edge of the front end of the loose sleeve 31, and the outer diameter of the loose sleeve 31 is set A loosening spring 33 is combined, and a loosening handle 36 is placed outside the loosening spring 33; the inner edge of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com