Variable resistance

A resistor, variable technology, applied in the direction of surface mountable resistors, sliding contact resistors, etc., can solve problems such as terminal short circuit, achieve high productivity, improve the effect, and improve the effect of suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

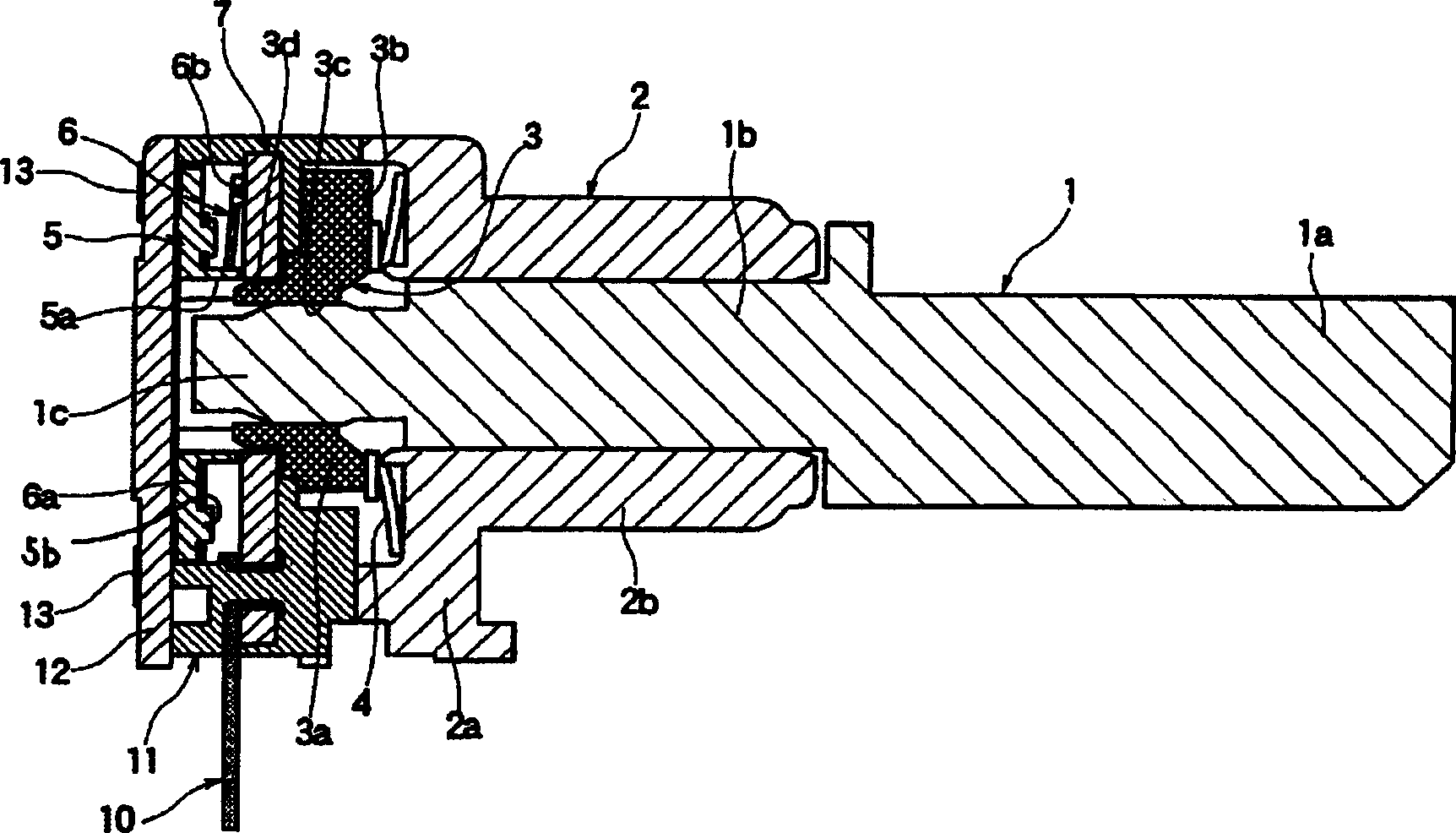

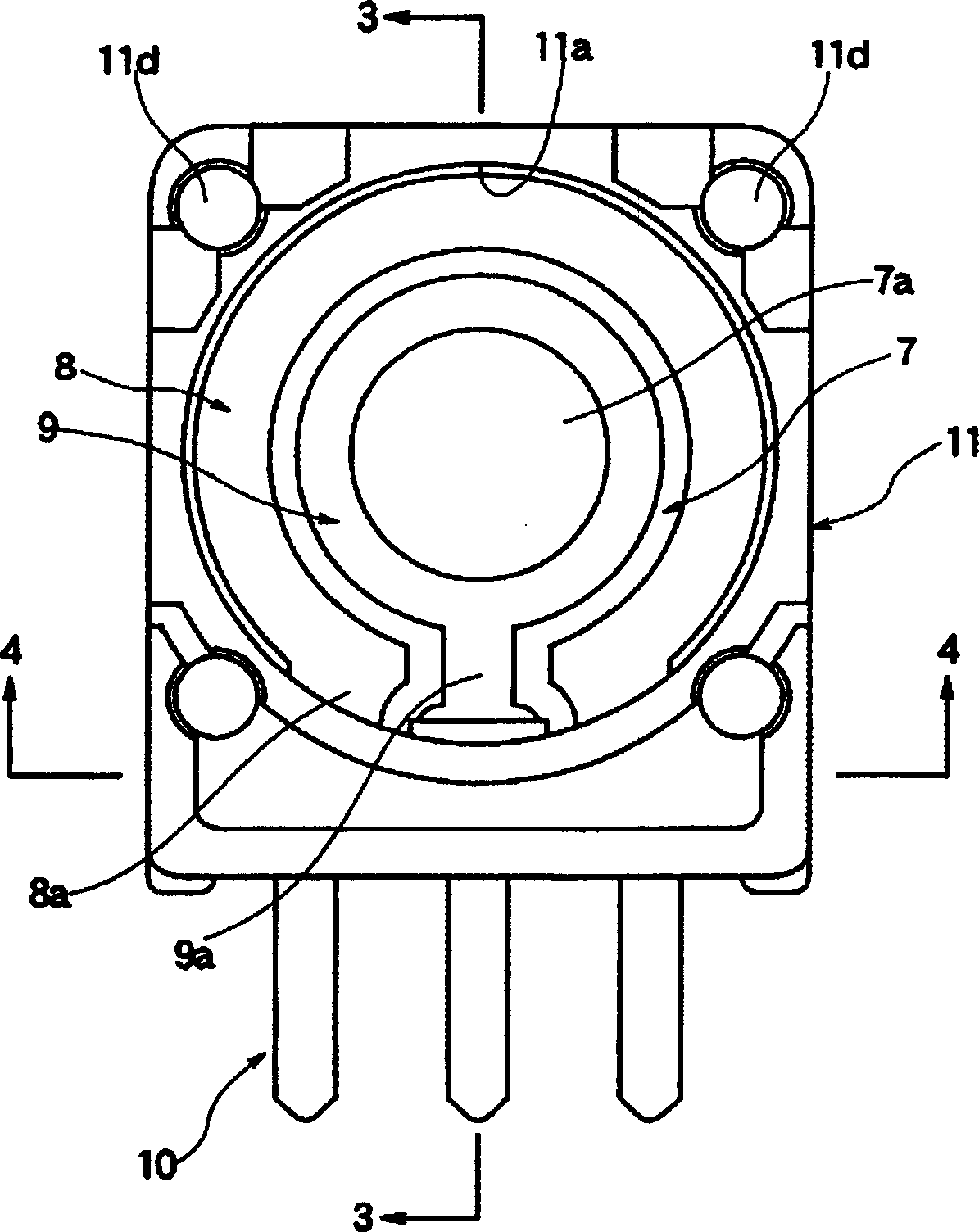

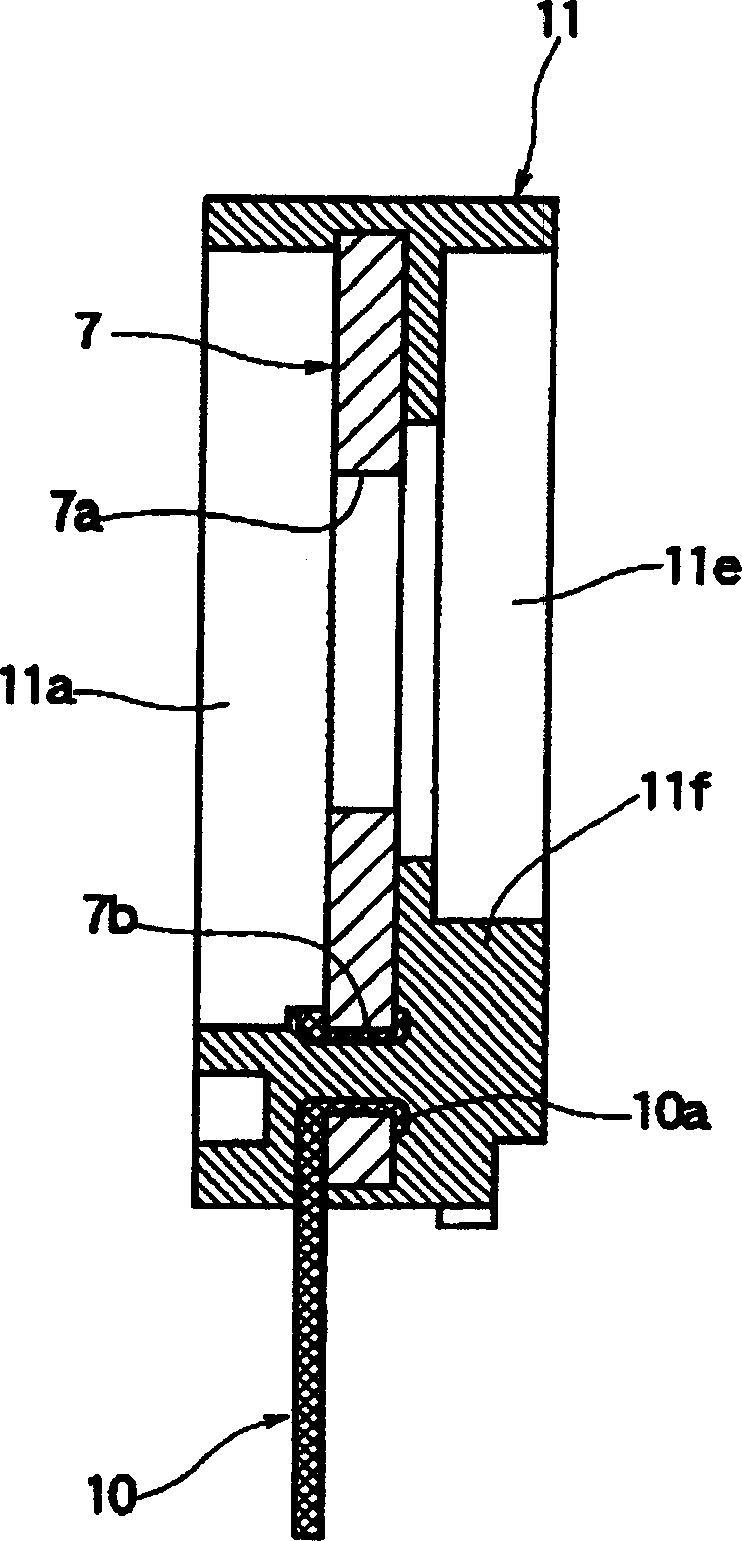

[0033] the following, Figure 1 to Figure 8 Embodiments of the present invention are shown. figure 1 is a sectional view showing a variable resistor of the present invention, figure 2 It is a front view showing an insulating substrate and a holding member of a variable resistor of the present invention, image 3 yes figure 2 In the sectional view of line 3-3, Figure 4 yes figure 2 sectional view of line 4-4 in, Figure 5 It is a front view showing the terminal insulating substrate of the variable resistor of the present invention, Figure 6 yes Figure 5 rear view of Figure 7 yes Figure 5 The sectional drawing of line 7-7, Figure 8 It is a front view showing the insulating substrate of the varistor of the present invention.

[0034] In the figure, the variable resistor of the present invention is composed of the following parts, including: an operation shaft 1; a shaft seat 2 that rotatably holds the operation shaft 1; The driving body 3 rotated by the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com