Mono-walled wire spring hole

A spring hole and wire spring technology, which is applied in the field of single-wall wire spring holes, can solve the problems of large size of wire spring holes and inability to meet the electrical isolation spacing requirements of small-pitch electrical connectors.

Inactive Publication Date: 2006-11-01

赏广鸣

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the current existing inner and outer double-wall wire spring holes have large dimensions and cannot meet the electrical isolation spacing requirements of small-pitch electrical connectors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

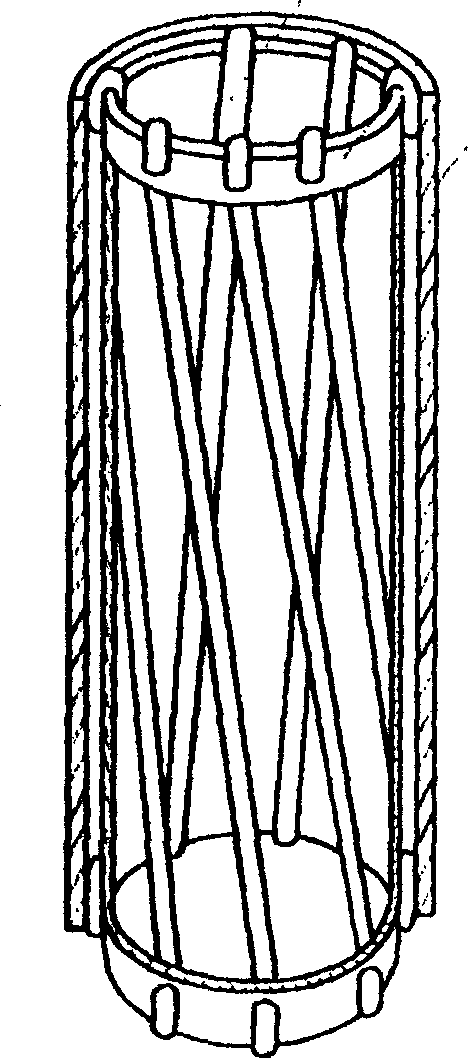

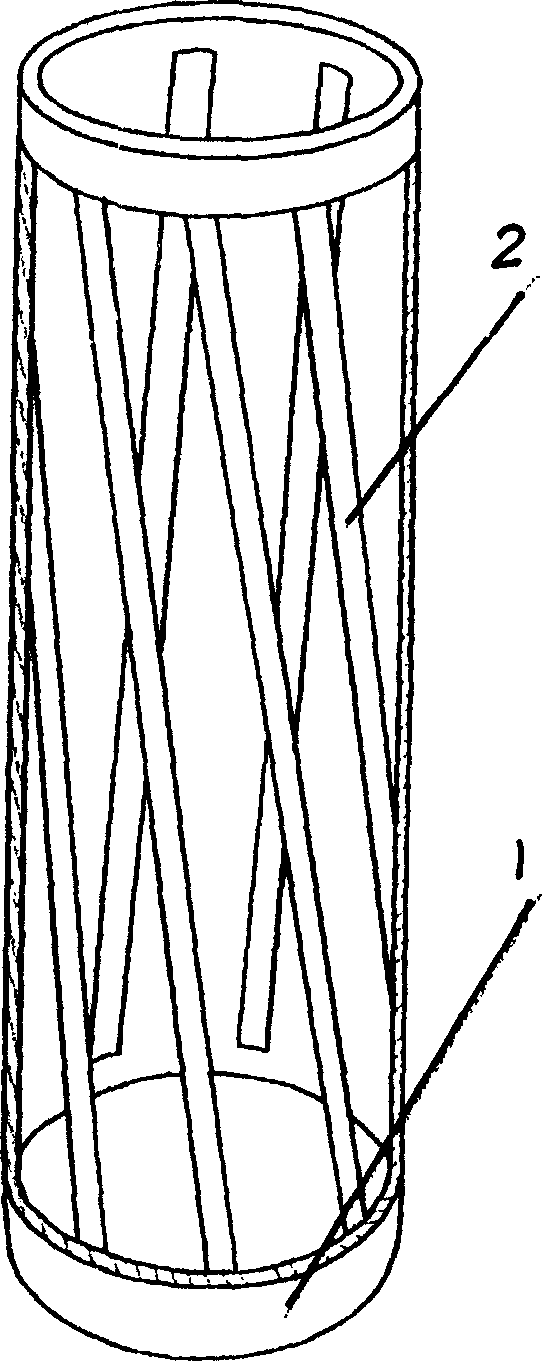

[0011] Such as figure 2 A single-wall wire spring hole is shown, which has a metal tube 1, and a plurality of wire springs 2 are arranged on the inner wall of the tube, and the two ends of each wire spring are fixedly connected with the inner wall of the metal tube. A plurality of wire springs are arranged in a helical shape. A plurality of wire springs can also be arranged in the form of a single-leaf rotary hyperboloid.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention has only one metal tube, and on the inner wall of said metal tube multi wire springs are arrayed. Two ends of each wire spring are secured on the inner wall of said metal tube. Multi wire springs are arrayed in a helical shape so as to show a hyperboloid of revolution of one sheet shape. The invention saves an outer tube required by an original double wall wire spring hole so as to reduce the size of wire spring hole.

Description

technical field [0001] The invention belongs to electric connectors, in particular to a single-wall wire spring hole. Background technique [0002] Existing wire spring holes have inner and outer double walls at present, and the bending at the two ends of the wire spring is clamped between the inner and outer double walls. Because the current existing inner and outer double-wall wire spring holes have large dimensions and cannot meet the electrical isolation spacing requirements of small-pitch electrical connectors. Small-pitch electrical connectors, such as 2.0mm-pitch electrical connectors, cannot use the existing internal and external double-walled wire spring holes to achieve miniaturized and highly reliable wire spring connection technology. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a single-wall wire spring hole. The miniaturization of the wire spring hole electrical connector can be achieved. [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01R13/33H01R43/00

Inventor 赏广鸣

Owner 赏广鸣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com