Method for mounting carrier belt and programmable read-only memory

A read-only memory, carrier tape technology, applied in read-only memory, static memory, information storage, etc., can solve the problems of shortening operation time, time-consuming, loss of batch writer and installation machine process continuity, etc. , to achieve the effect of shortening the writing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

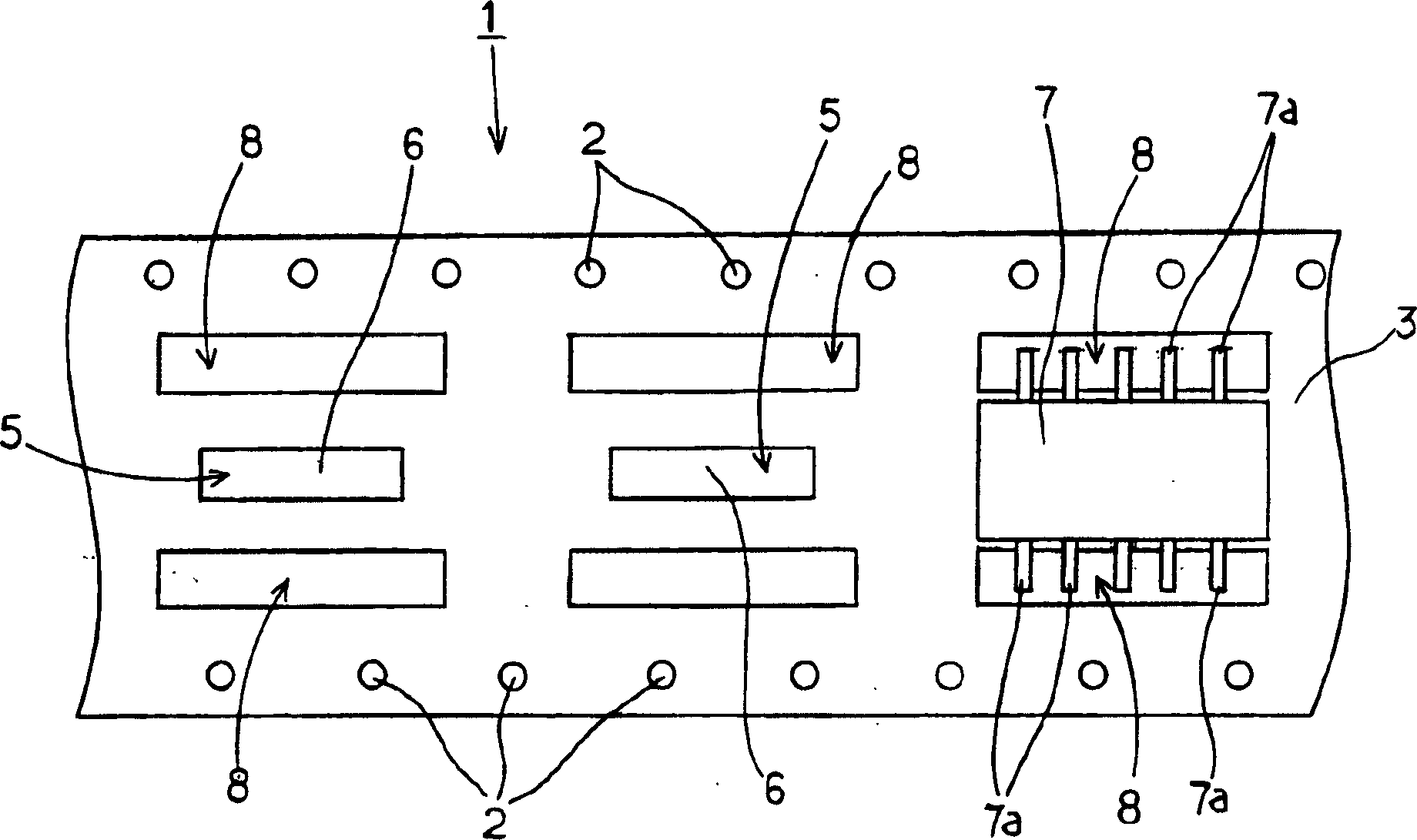

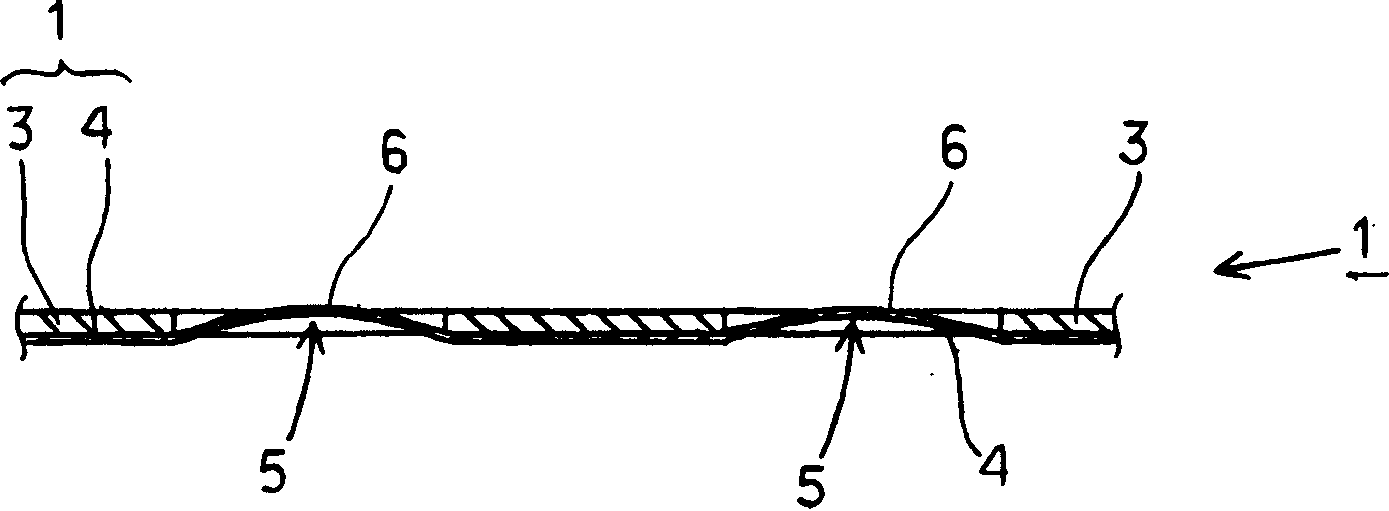

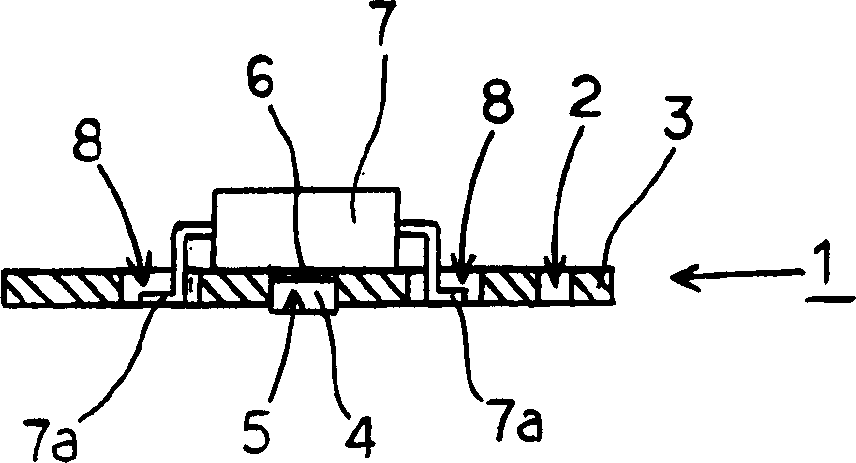

[0040] Refer below Figure 1 to Figure 3 The carrier tape 1 of the present invention will be described. figure 1 It is a top view of carrier tape 1. Such as figure 2 As shown, the conveyor belt 1 includes: a belt main body 3 formed into a belt shape by vinyl resin, paper, etc., and a back surface ( figure 2 Adhesive sheet 4 on the surface below). On the belt main body 3, in its lateral width ( figure 1 In the approximate center of the width in the up and down direction), along the length direction of the belt main body 3, there are window holes 5, 5 with a slender and rectangular outline at certain intervals, and the length direction is used as the load In the conveying direction of the belt 1, a plurality of sprocket holes 2, 2, . . . Furthermore, between both sides of each window hole 5 and the sprocket hole 2, a rectangular through-hole 8 parallel to the window hole 5 is drilled.

[0041] The adhesive sheet 4 is formed as a tape that is equal to or slightly thinner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com