Method for preparing aluminium 20 tin semi solid slurry by mechanically stirring

A semi-solid slurry, mechanical stirring technology, applied in chemical instruments and methods, mixers, dissolution and other directions, can solve problems such as complex equipment structure, and achieve the effect of solving complex equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

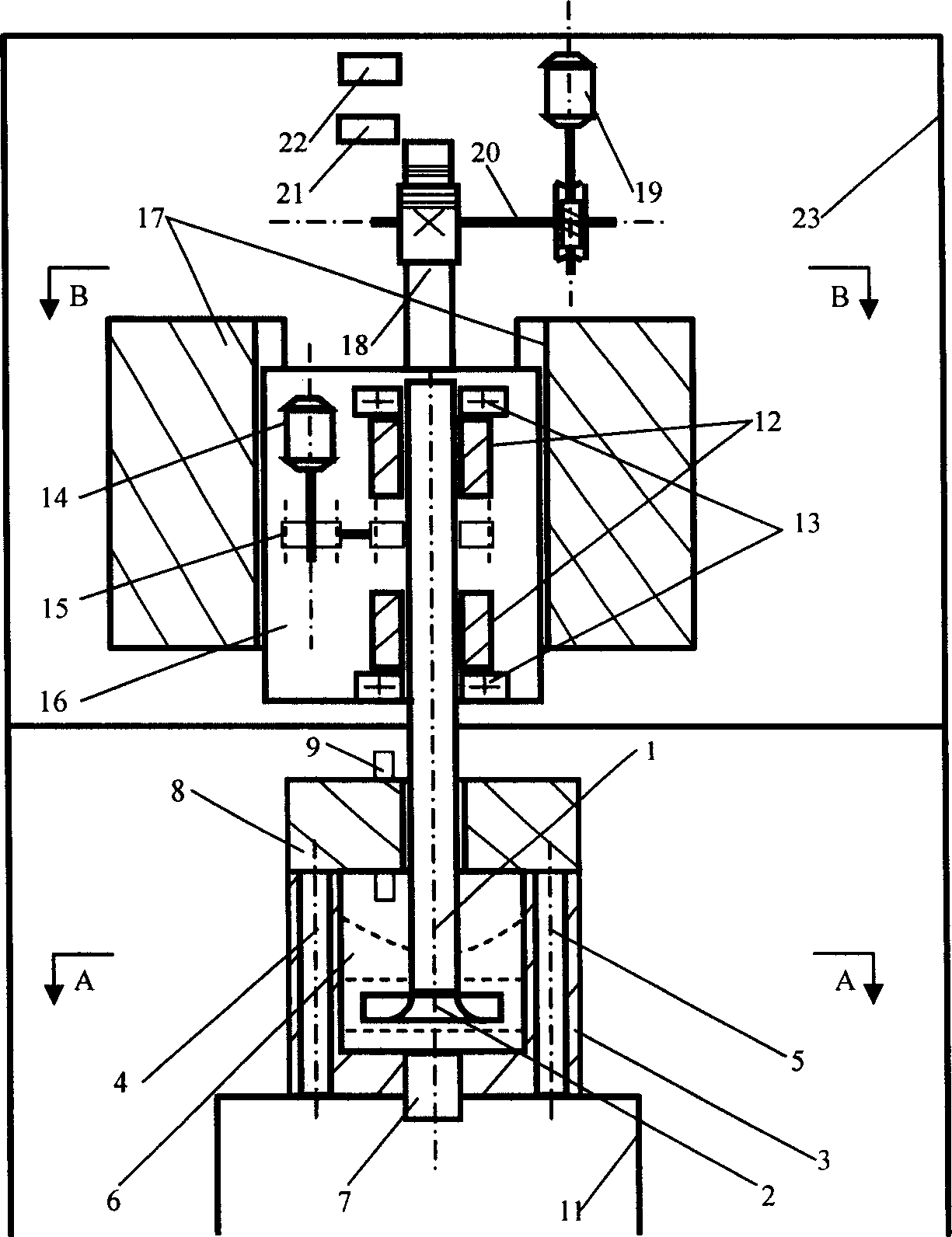

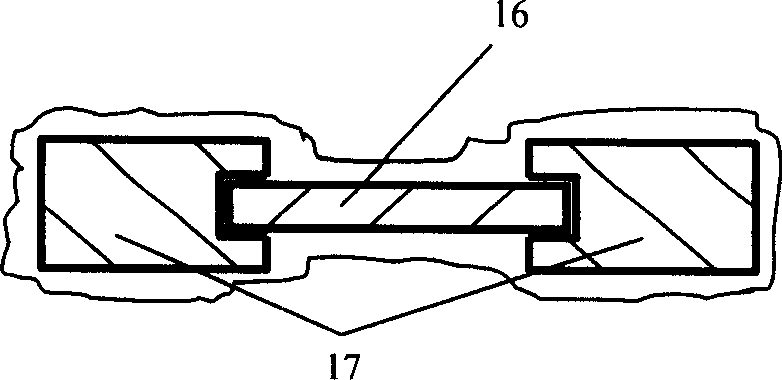

[0023] The specific description of the aluminum 20 tin semi-solid slurry device prepared by the inventive method in conjunction with the accompanying drawings is as follows:

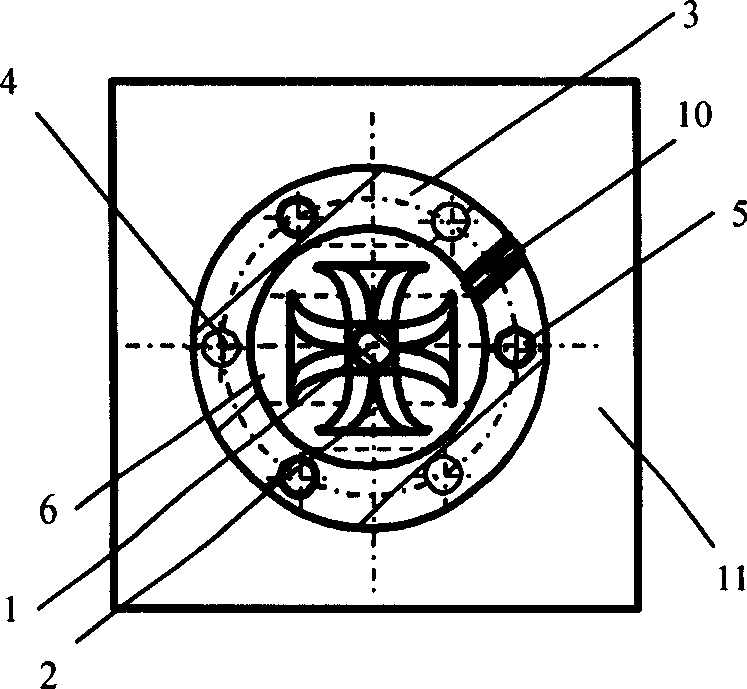

[0024] The mechanical stirring preparation device for aluminum 20 tin semi-solid slurry is mainly composed of a mechanical stirrer and its drive and up and down movement control device, graphite crucible 3, upper cover 8, plug 7, Ar gas pipe 9 and thermocouple 10.

[0025] The graphite crucible 3 is fixed on the base frame 11 by means of mechanical connection, and the heating pipe 4 and the cooling pipe 5 are evenly distributed in the wall, and are respectively connected with the external power supply and the cooling liquid supply system;

[0026] The mechanical stirrer is composed of a circular stirring rod 1 and four double-sided double-curved blades 2, and the material is heat-resistant ceramics; the lower end of the circular stirring rod 1 is square, and its four sides are tangent to the circular stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com