Sleeve type seal piece

A kind of seal, sleeve type technology, applied in the direction of pipe/pipe joint/pipe fitting, through element, sleeve/socket connection, etc., can solve the problems of air leakage, poor sealing, simple structure limitation, etc., saving labor and saving It is easy to use, easy to install and maintain, and has a large sealing surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

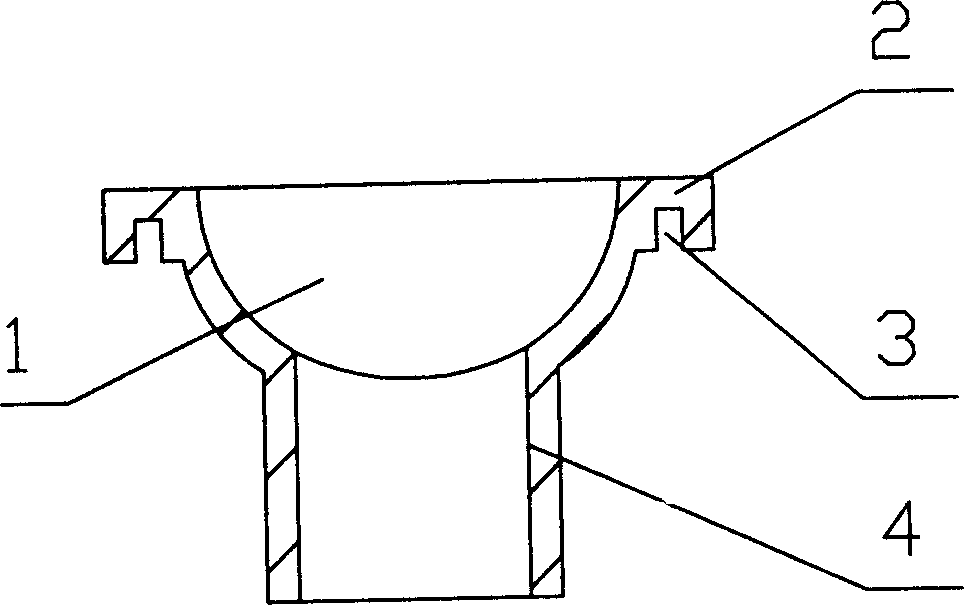

[0019] figure 1 Shown is the front view structure schematic diagram of the present invention.

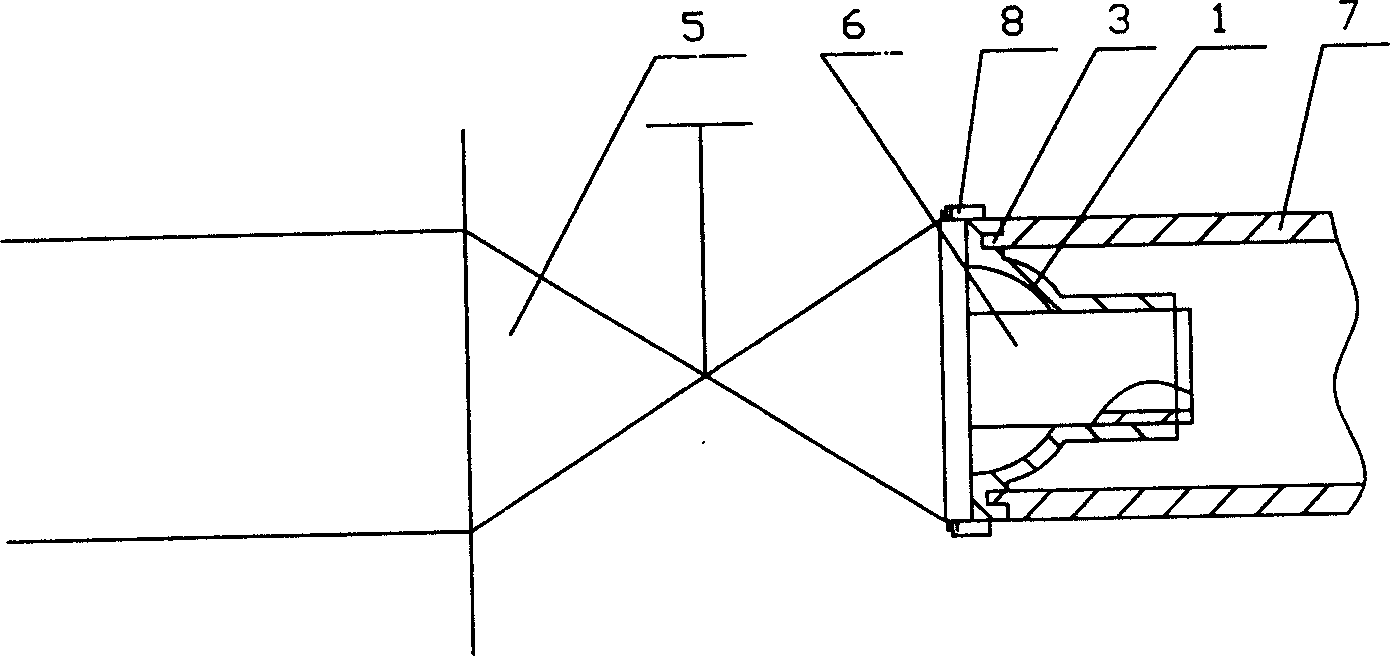

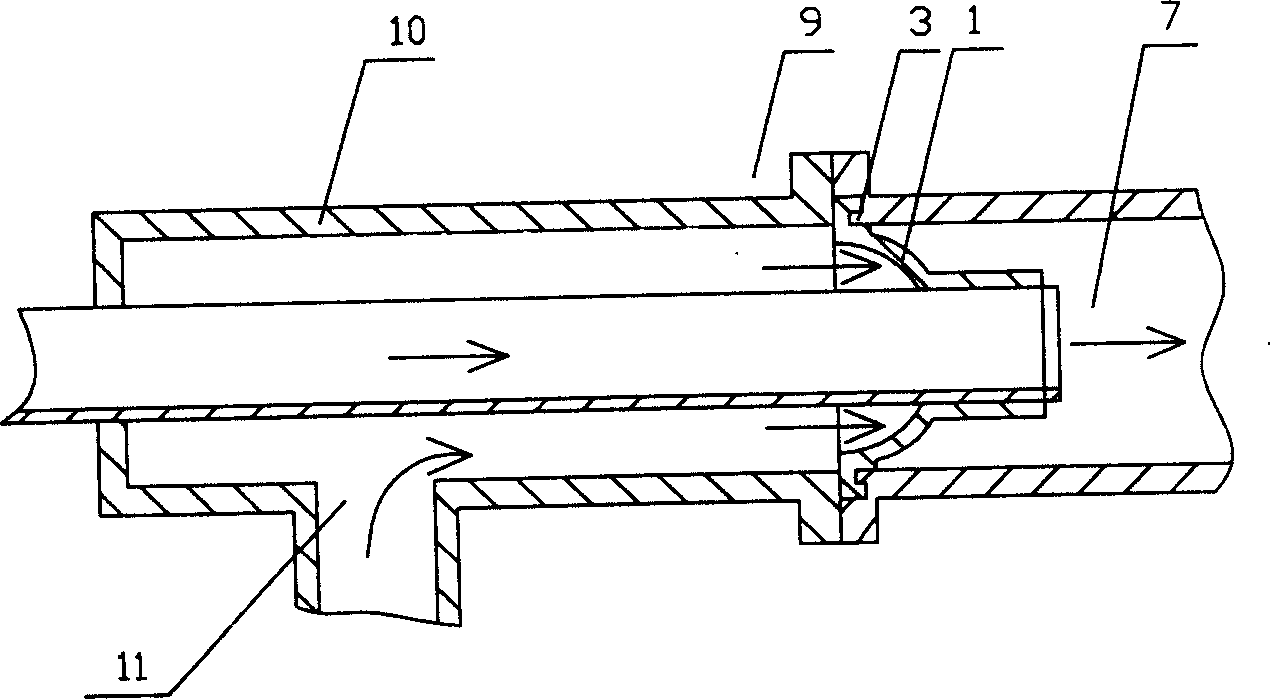

[0020] figure 2 Shown is that the present invention is one of embodiment, is to connect the sealing member 6 of metal tube at the mouth of the compressed air line valve 5, and install the sleeve type seal made of latex in the mouth of the outer tube 7 that is discharged. Part 1, one end of the casing type seal 1 is a flange seal body 2, and the other end is a straight tube seal body 4, and the flange-shaped seal body 2 and the straight tube-shaped seal body 4 are integrated by an arc surface transition For a hollow sleeve type seal 1, the sealing surface between the discharged outer tube 7 and the flange sealing body 2 is concave on the flange surface, and the end surface of the discharged outer tube 7 is convex to form a convex-concave sealing surface 3, and the metal The sealing end of the pipe seal 6 is inserted into the straight pipe seal body 4 of the casing seal 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com