External air flow distribution pulsation fluidizing drying device

A technology of airflow distribution and drying equipment, which is applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc. It can solve the problems of many manual operations, harsh working conditions, and low production efficiency, and achieve the effect of improving pulsation , Improve the drying effect, the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

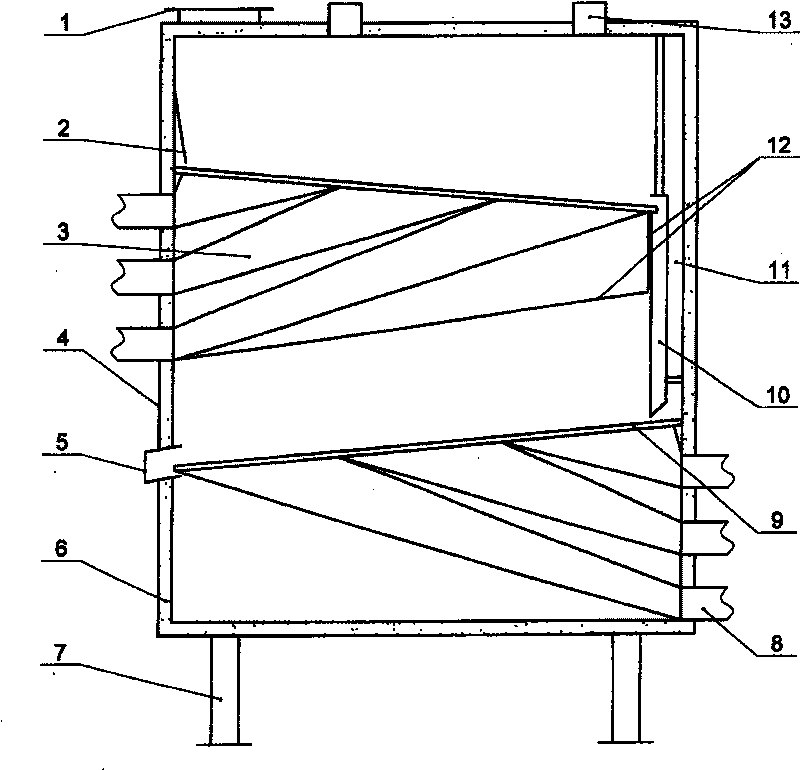

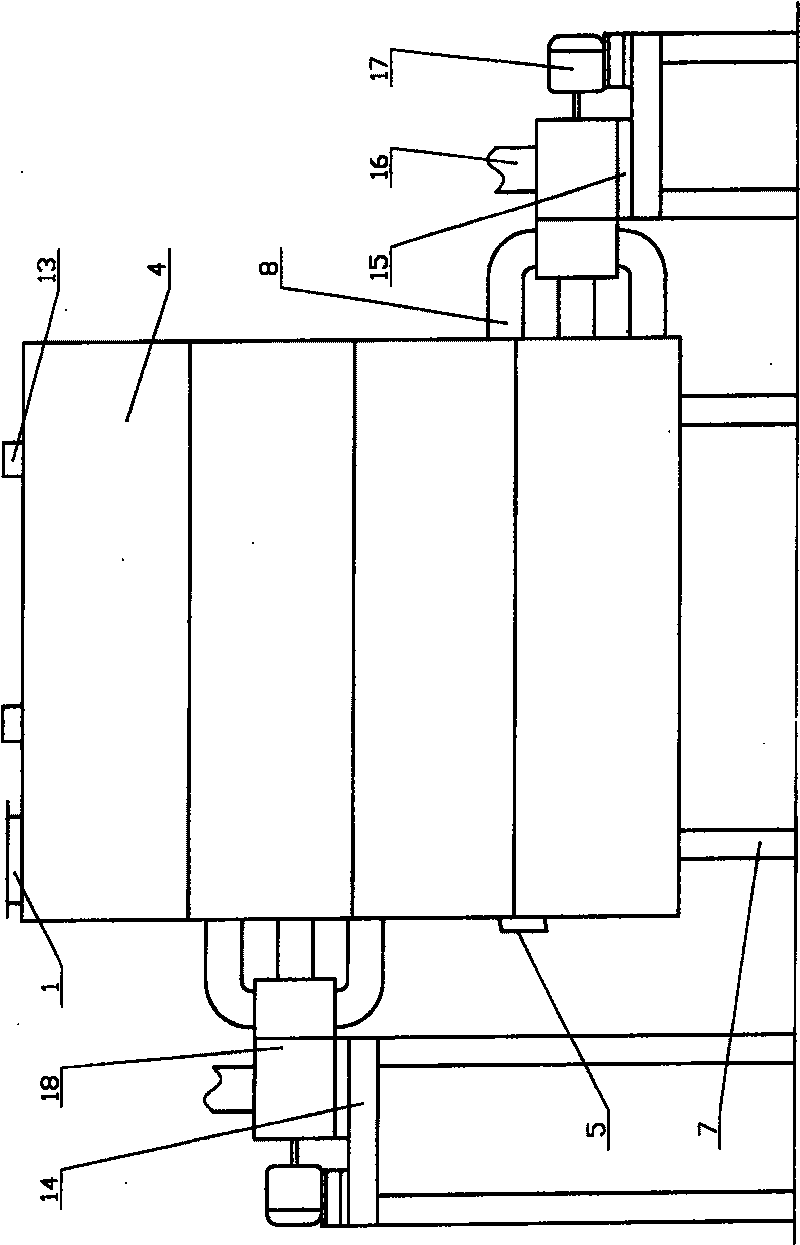

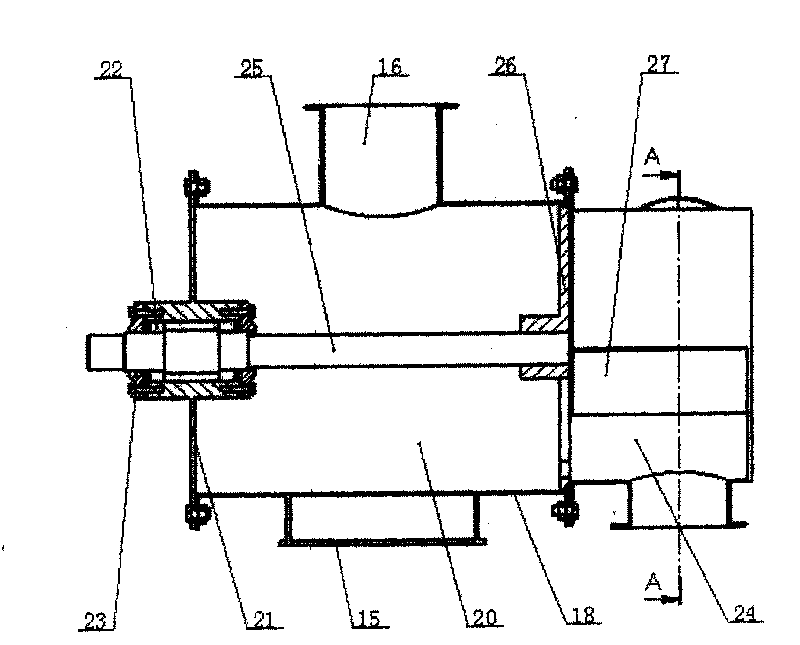

[0021] 1. Feed inlet 2, material guide plate 3, "funnel" pipe 4, box body 5, discharge port 6, insulation layer 7, outrigger 8, air duct 9, fluidized bed 10, material guide device 11, falling Material channel 12, partition 13, air outlet 14, bracket 15, support 16, air inlet 17, motor 18, housing 19, fan-shaped hole 20, air supply chamber 21, end cover 22, bearing 23, bearing cover 24 , distribution chamber 25, transmission shaft 26, rotating disk 27, deflector

[0022] exist Figure 1-7 In the shown embodiment, the top of the box body 4 is provided with a material inlet 1 and an air outlet 13 , the lower part is provided with a material outlet 5 , and the bottom is provided with a leg 7 . Two layers of fluidized beds 9 with opposite inclination directions are arranged inside the box body 4 , the bed surface of the fluidized bed 9 is connected with the inner wall of the box body 4 , and the inclination angle of the fluidized bed 9 is adjustable. The bed surface gradually dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com