Shaft retaining ring

A technology of positioning rings and protrusions, applied in the field of positioning rings, can solve problems such as damaging the stability of the installation state, and achieve the effects of facilitating installation/disassembly operations, eliminating the possibility of bouncing, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

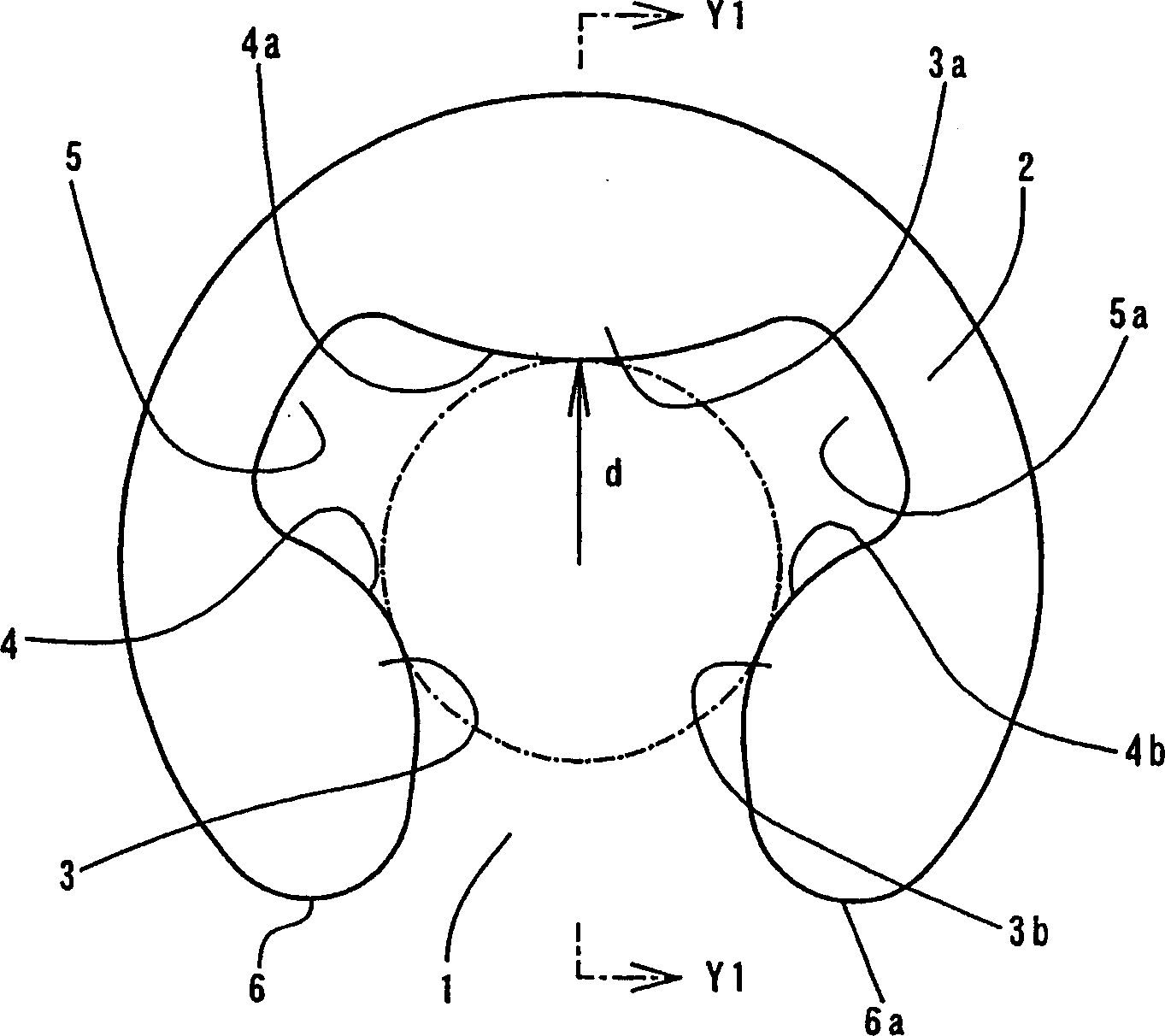

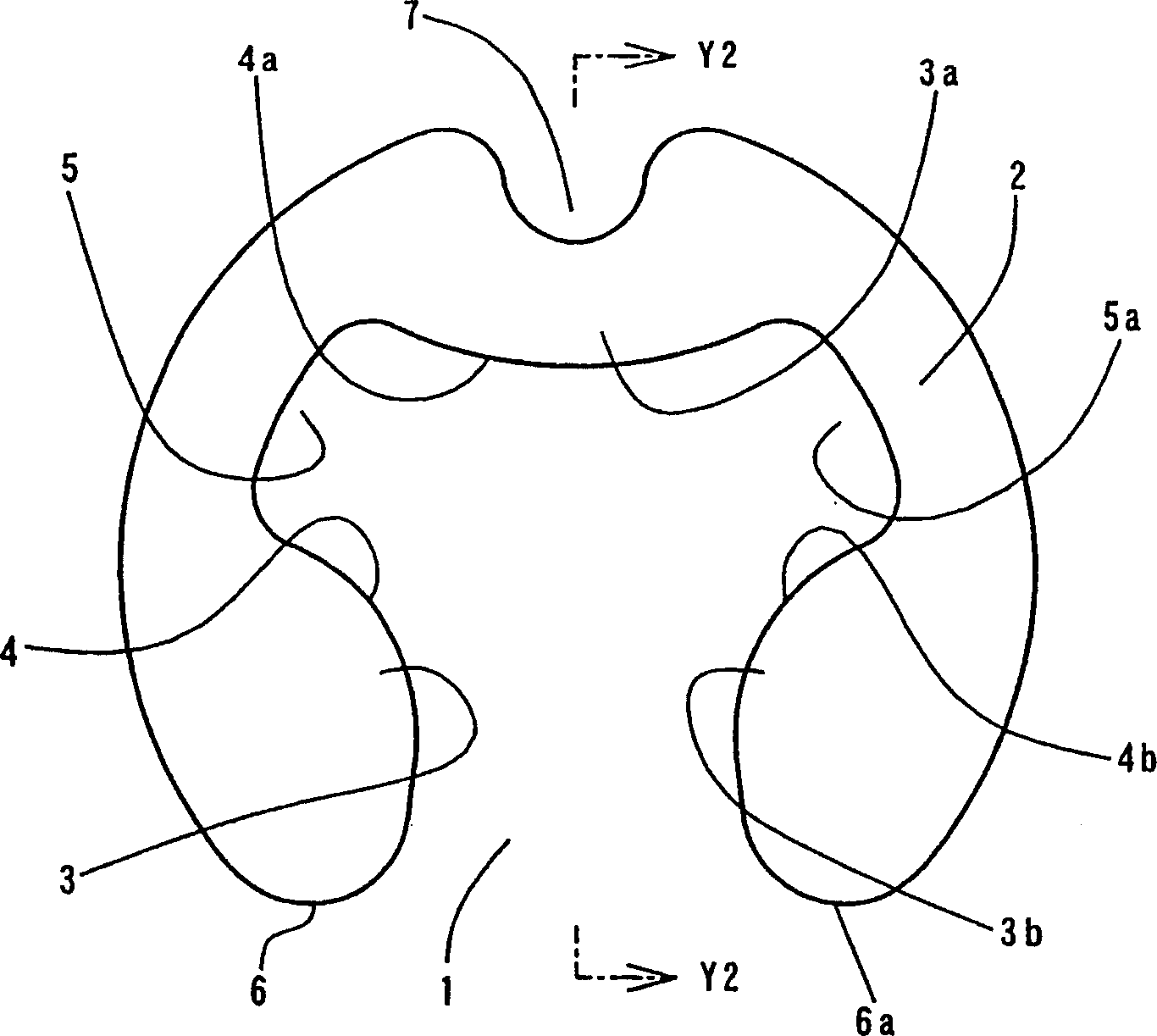

[0038] Embodiments of the present invention will be described below with reference to the accompanying drawings.

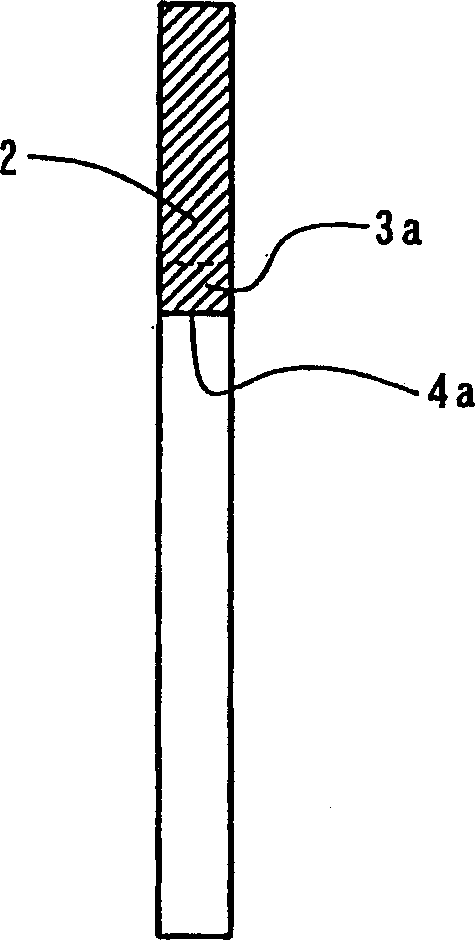

[0039] The shaft positioning ring according to one embodiment of the present invention is punched symmetrically. On the inner periphery of the C-shaped base material 2 are integrally formed a plurality of lobes 3, 3a, . . . which function as protrusions. The base material 2 has an opening portion 1 at one position on the outer periphery thereof. In this way, the inner edges 4, 4a... of the lobes 3, 3a... are formed into a convex arc shape which circumscribes the outer peripheral surface of the mounting area on the axis S. As shown in FIG. The spaces between adjacent lobes 3, 3a are made as inner notches 5, 5a....

[0040] The base material 2 is made of a metal having excellent elasticity, such as spring steel or spring stainless steel. The diameter of the circle tangent to the inner edges 4, 4a... of all lobes 3, 3a... is set to be slightly smaller than the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com