Shape memory alloy self-restoration rubber damper

A memory alloy and memory alloy wire technology, applied in bridge parts, bridge construction, bridges, etc., can solve problems such as limited energy consumption capacity, and achieve the effects of reducing dynamic response, convenient construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

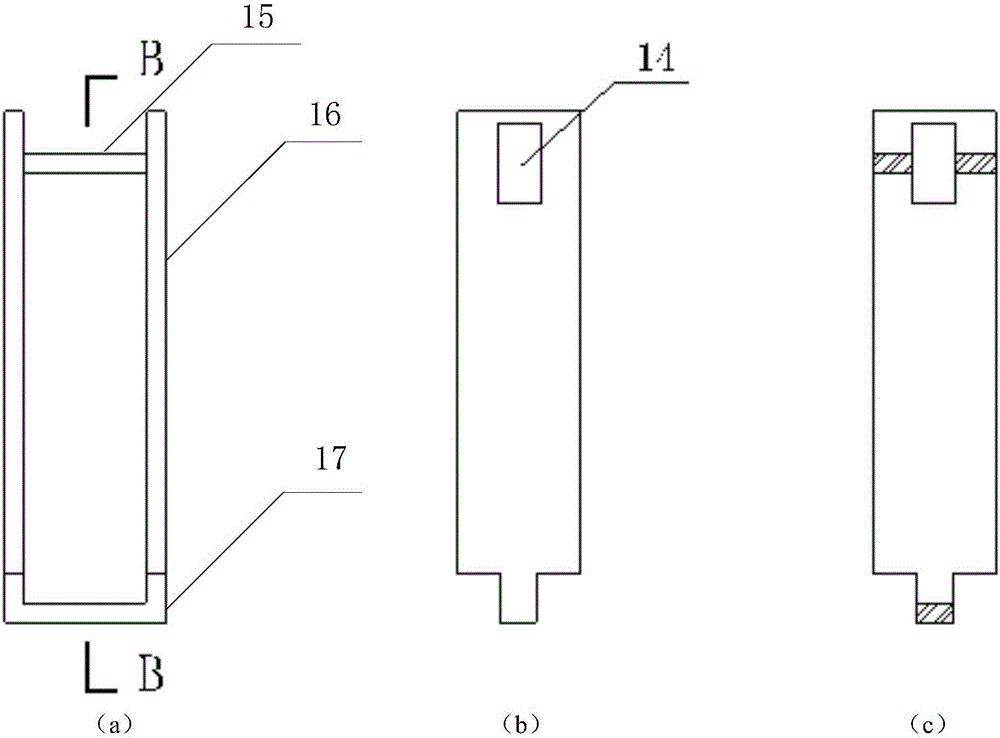

[0024] In the accompanying drawings, one shape memory alloy wire is used as an example.

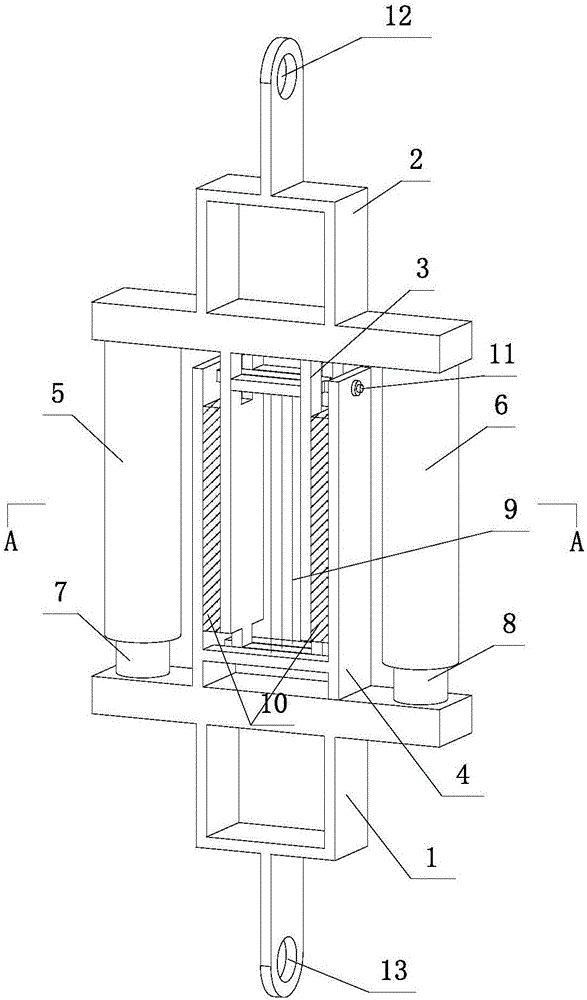

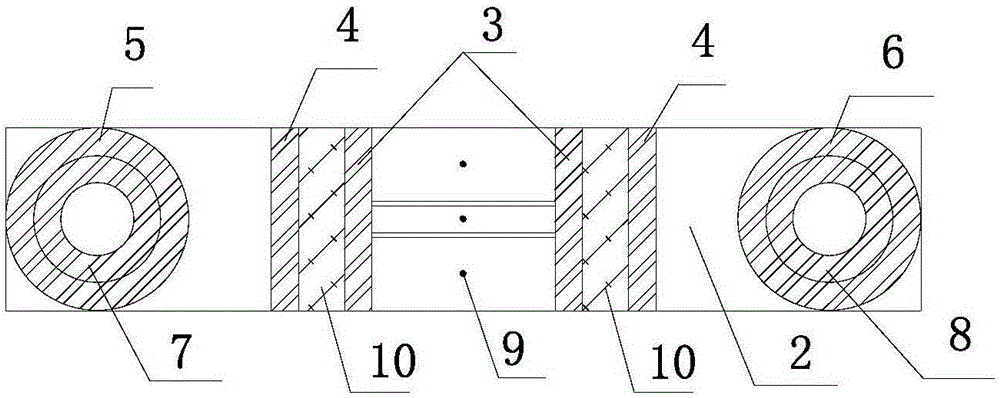

[0025] Such as figure 1 , figure 2 As shown, a shape memory alloy self-resetting rubber damper includes a pair of upper main board 2 and lower main board 1 symmetrically distributed up and down, the upper sub board 3 is fixed on the upper main board 2 by welding, and the lower sub board 4 is fixed on the lower board by welding. On the main board 1, the upper sub-board 3 and the lower sub-board 4 are inserted into each other, two rubber plates 10 are placed between the upper sub-board 3 and the lower sub-board 4, and a superelastic shape memory alloy is arranged on the inner side of the upper sub-board 3 wire 9; a pair of cylinders are respectively connected to the left and right sides below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com