Development machine for crushing existing concrete conduit

A roadheader and concrete technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of increased turnover torque, heavy weight, and affecting work efficiency, and achieve the effect of reduced power and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

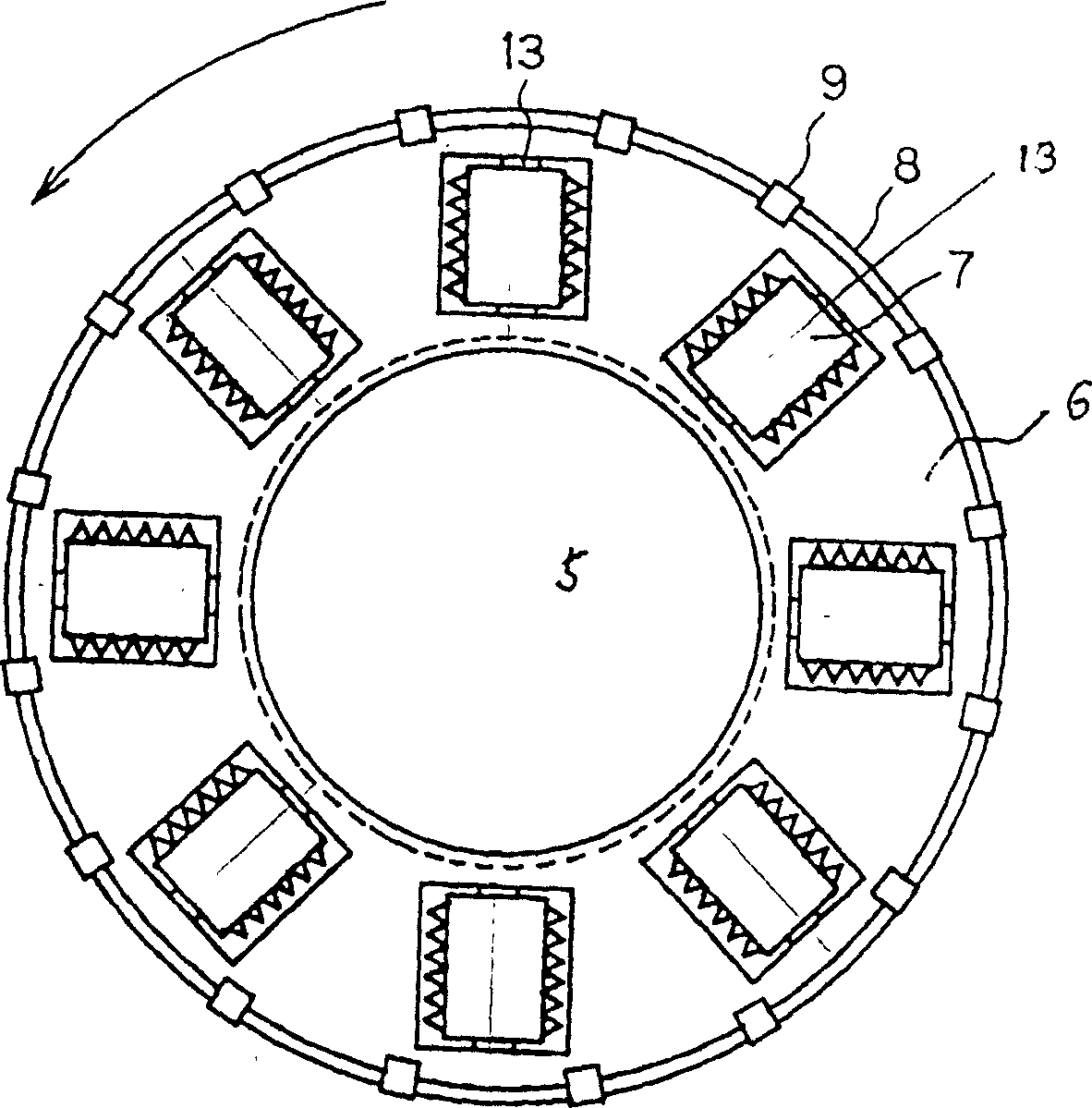

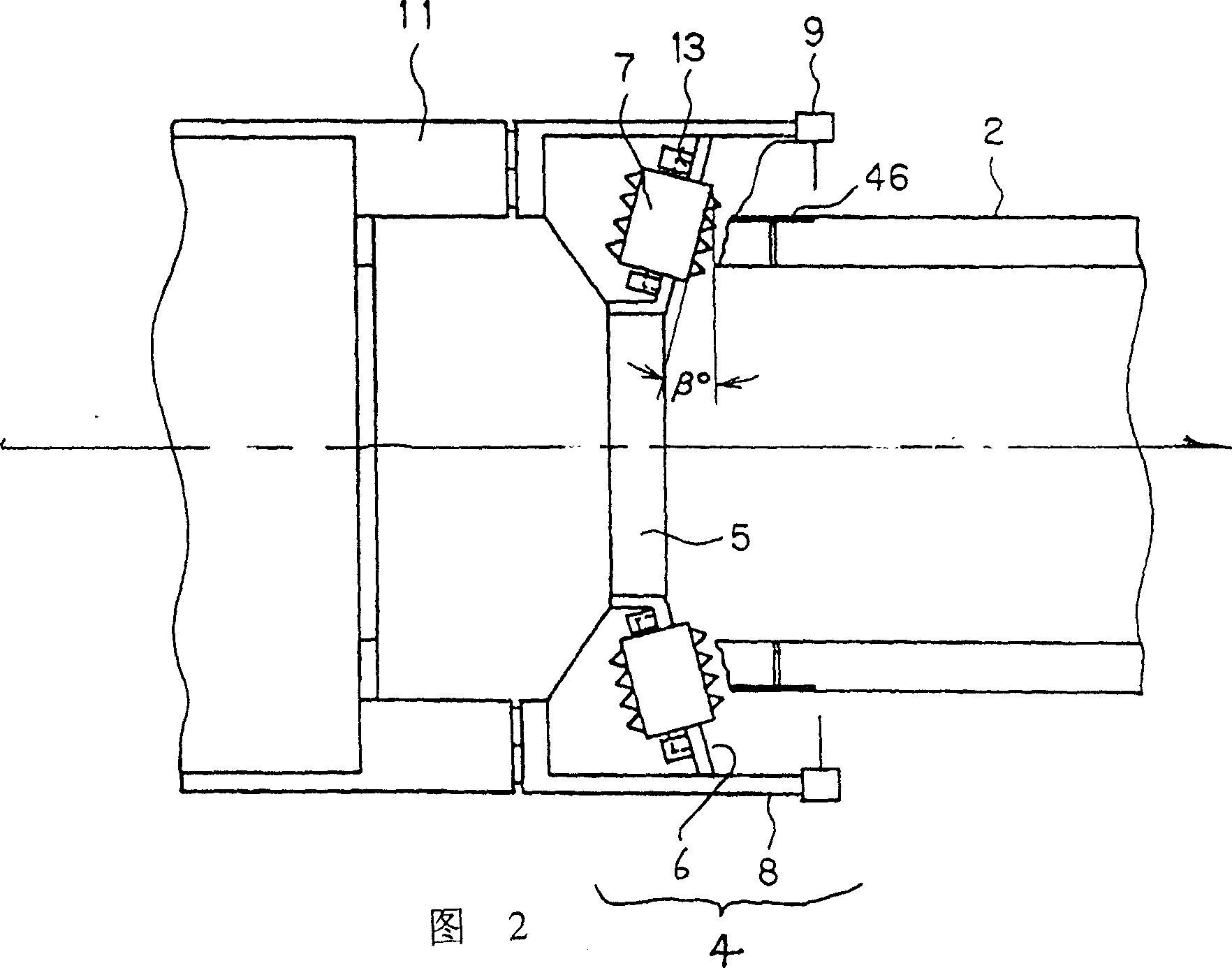

[0026] Example 1, see figure 1 As shown in Figure 2, the tunnel boring machine used to break the existing concrete pipe has an inner diameter larger than the outer diameter of the existing concrete pipe 2 buried in the ground. In front of the main body of the roadheader, a wheel-shaped head 4 is installed only at a ring position necessary for crushing the existing concrete pipe 2 and is rotated by a driving source. The head 4 has a wheel-shaped cutter head 6. The center of the wheel-shaped cutter head 6 forms a large opening 5 that can enter and exit the workers, materials, working machines, and crushed objects. The wheel-shaped cutter head 6 is separated by a certain distance every time. A freely rotatable shaft 13 is installed along the radius, and a cylindrical hob 7 is installed on each rotating shaft 13.

[0027] A waterproof wall (not shown in the figure) with an opening in the center is installed at the rear of the wheel-shaped handpiece 4. A driving device 11 is installed...

Example Embodiment

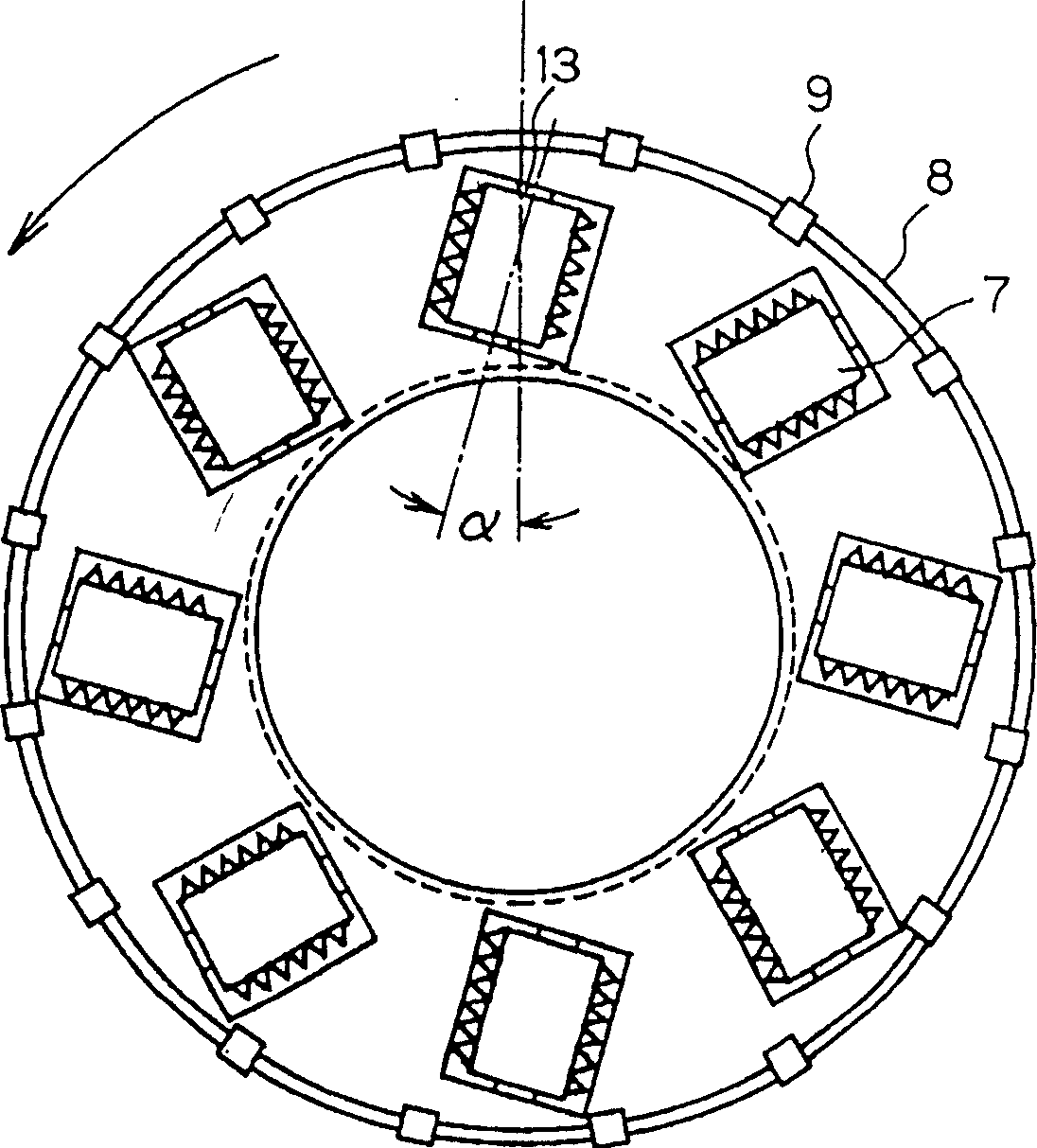

[0030] Example 2, see image 3 , A roadheader for crushing existing concrete pipes. On its wheel-shaped head 4, the circumferential position of the proximal end of the rotating shaft 13 equipped with the hob 7 is shifted to the side of the rotation direction to form a displacement device with the radial direction. The inclination angle α, the inclination angle α should be 3°~45°. When the inclination angle α in the radial direction is below 3°, and the inclination angle in the radial direction is close to the angle of the radius, the steel bars and interface steel broken and cut by the hob 7 will be squeezed into the ground and cannot be removed and recycled; When the inclination angle α in the radial direction is greater than 45°, the crushing and cutting force of the hob 7 will decrease. The structure of the second embodiment can prevent the crushing and cutting force of the hob 7 from being reduced, and facilitate the removal and transportation of crushing and cutting debris fro...

Example Embodiment

[0031] Example 3 is the composition of Example 1 and Example 2. A roadheader used to break existing concrete pipes. On its wheel-shaped head 4, the proximal end of the rotating shaft 13 equipped with the hob 7 is moved to the axial direction. The rear side position is inclined to form an inclination angle β with the vertical line in the radial direction; in addition, the circumferential position of the proximal end of the connecting shaft 13 equipped with the hob 7 is shifted to the rotation direction by a device to form an inclination angle α with the radial direction. The structure of the third embodiment can prevent the crushing and cutting force of the hob 7 from being reduced, and it is easy to carry out the removal and transportation of crushing and cutting debris from the inner diameter side.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap