Suction muffler for compressor

A technology for silencers and compressors, which is used in machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problem of reducing the suction efficiency of the compressor, increasing the suction resistance, and it is difficult to improve the efficiency and reduce the noise at the same time. and other problems to achieve the effect of improving efficiency, reducing overall noise, and optimizing suction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

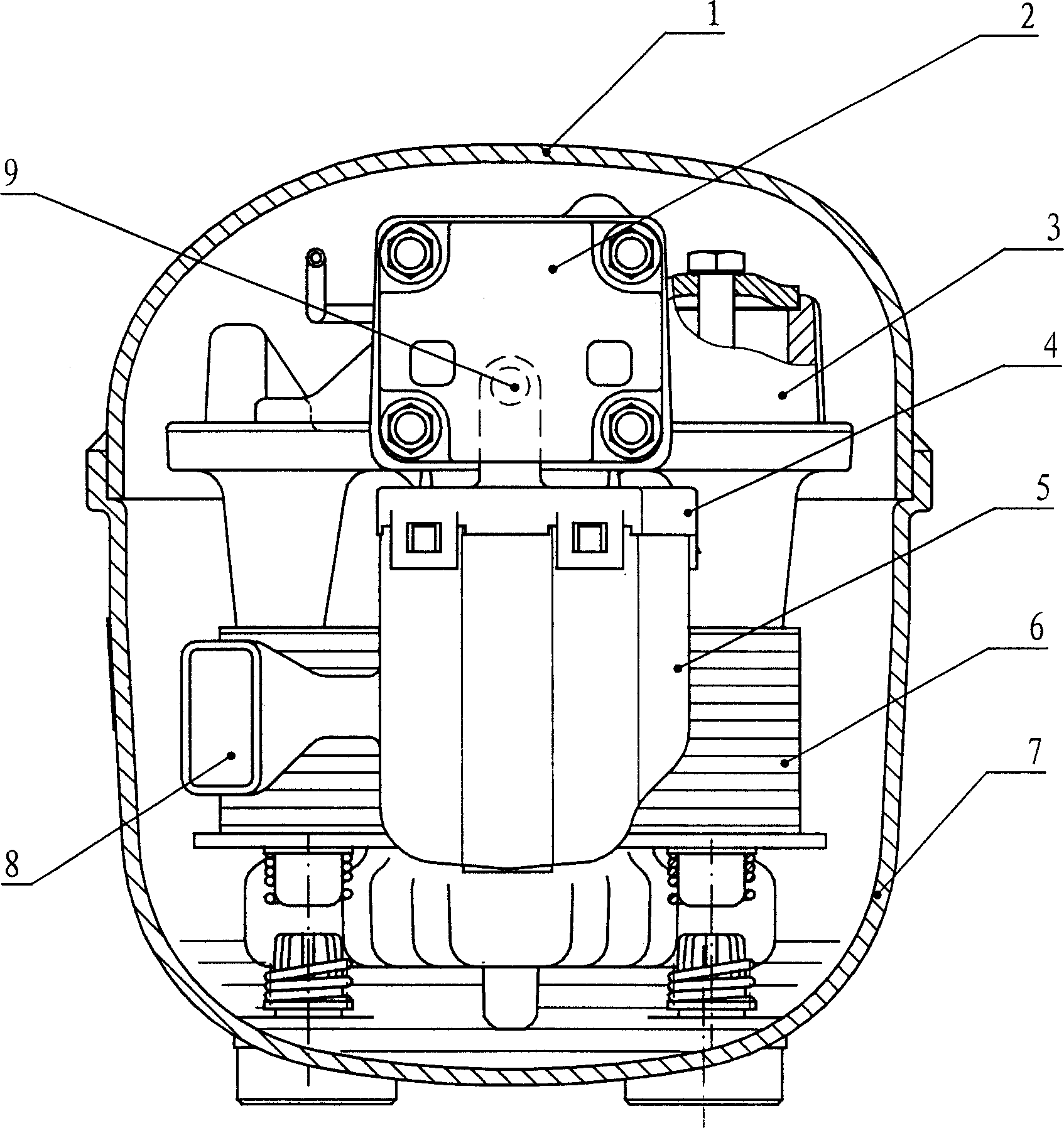

[0019] Such as figure 1 As shown, the fully enclosed refrigeration compressor is composed of an upper shell 1 and a lower shell 7. The closed steel shell is composed of mechanical components such as a crankcase 3 and a cylinder head 2, and electrical components such as a motor stator 6. Among them The motor stator 6 is fixed on the crankcase 3. The external structure of the suction muffler includes the upper cover 4, the lower shell 5 and the suction port 8, and the suction pipe 9 at the upper end is tightly fixed to the valve plate suction in the cylinder head 2. stomata.

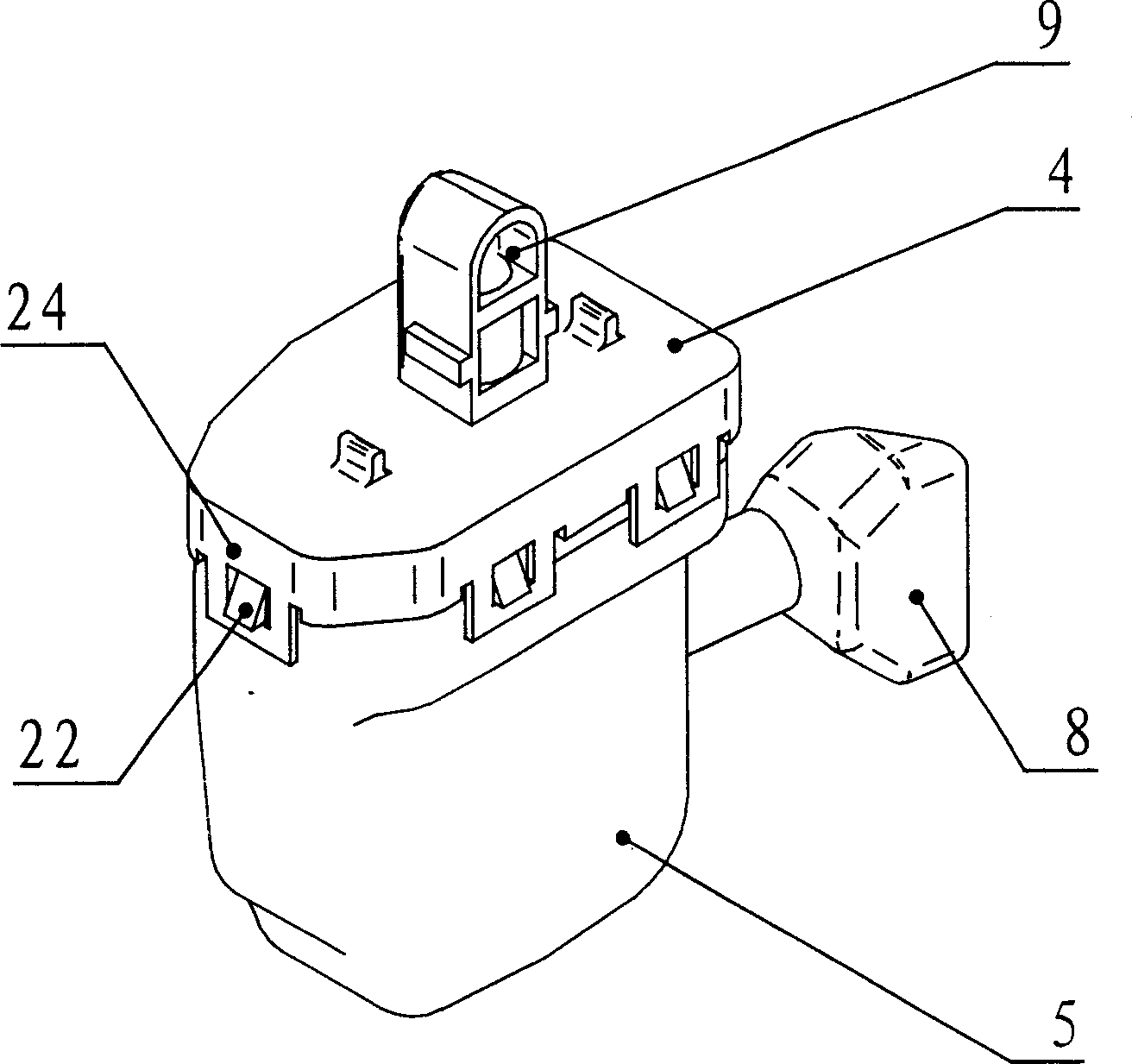

[0020] Such as figure 2 Shown is the assembled suction muffler, the upper cover 4 and the lower shell 5 are fastened by the hasp 24 and the clasp 22 . In order to ensure fastening effect, more than 4 hasps 24 are arranged on the upper cover 4 , and more than 4 hasps 22 are arranged on the lower shell 5 .

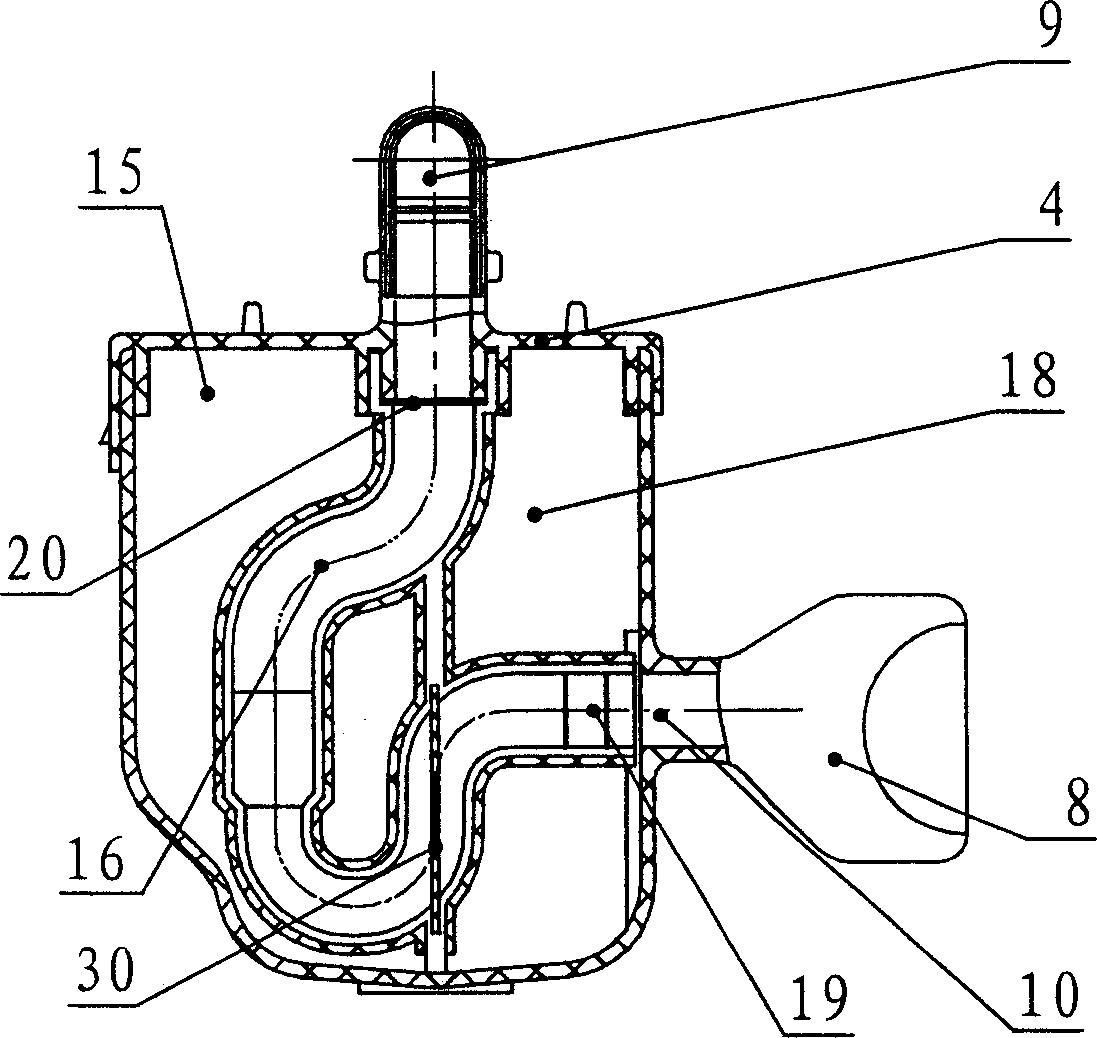

[0021] Such as image 3 As shown, the suction muffler is made up of loam cake 4, filter screen 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com