Spiral groove structured magneto-rheological damper

A magneto-rheological damper and spiral groove technology, applied in the field of damping devices, can solve the problems of lack of micro-optimization of damping force, etc., and achieve the effect of improving Coulomb force, preventing settlement, and preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

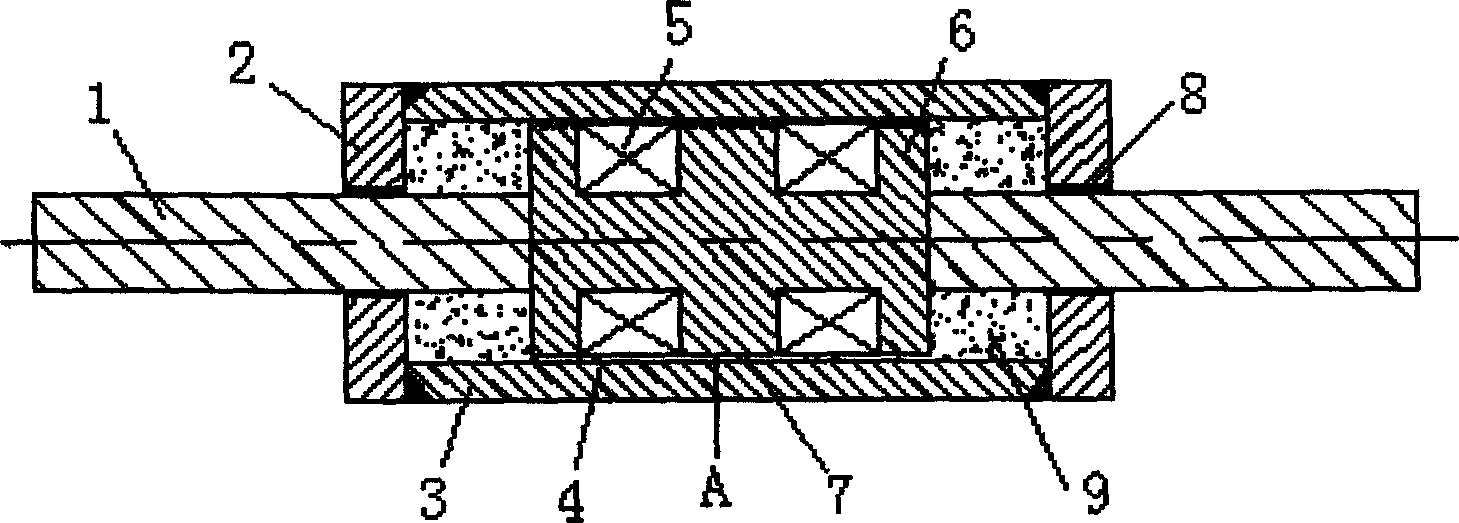

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

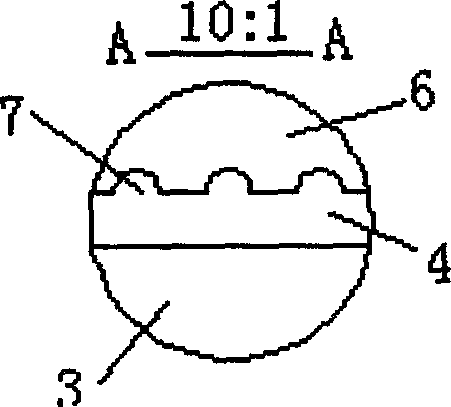

[0017] As shown in the accompanying drawings, it is a schematic design diagram of the magneto-rheological damper with a spiral groove structure of the present invention, which includes a cylinder 3, front and rear end covers 2, 8, a piston 6 arranged inside the cylinder, and the The piston rod 1 connected to the piston, the excitation coil 5 installed on the piston, a throttle passage 4 is arranged between the outer side wall of the piston and the inner side wall of the cylinder barrel, and the side wall of the piston is set Helical groove 7 is arranged. Said helical thread has a helix angle (the angle between the tangent of the helical thread on the cylindrical surface of the piston and the plane perpendicular to the axis of the threaded thread) between 5° and 60°.

[0018] If you want to avoid a large torque, you can reduce the helix angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com