Side lighting type lens assembly

A lens group, lighting technology, applied in lenses, optics, instruments, etc., can solve problems such as affecting the light output efficiency of the lens, damage to fragile structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the drawings.

[0021] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

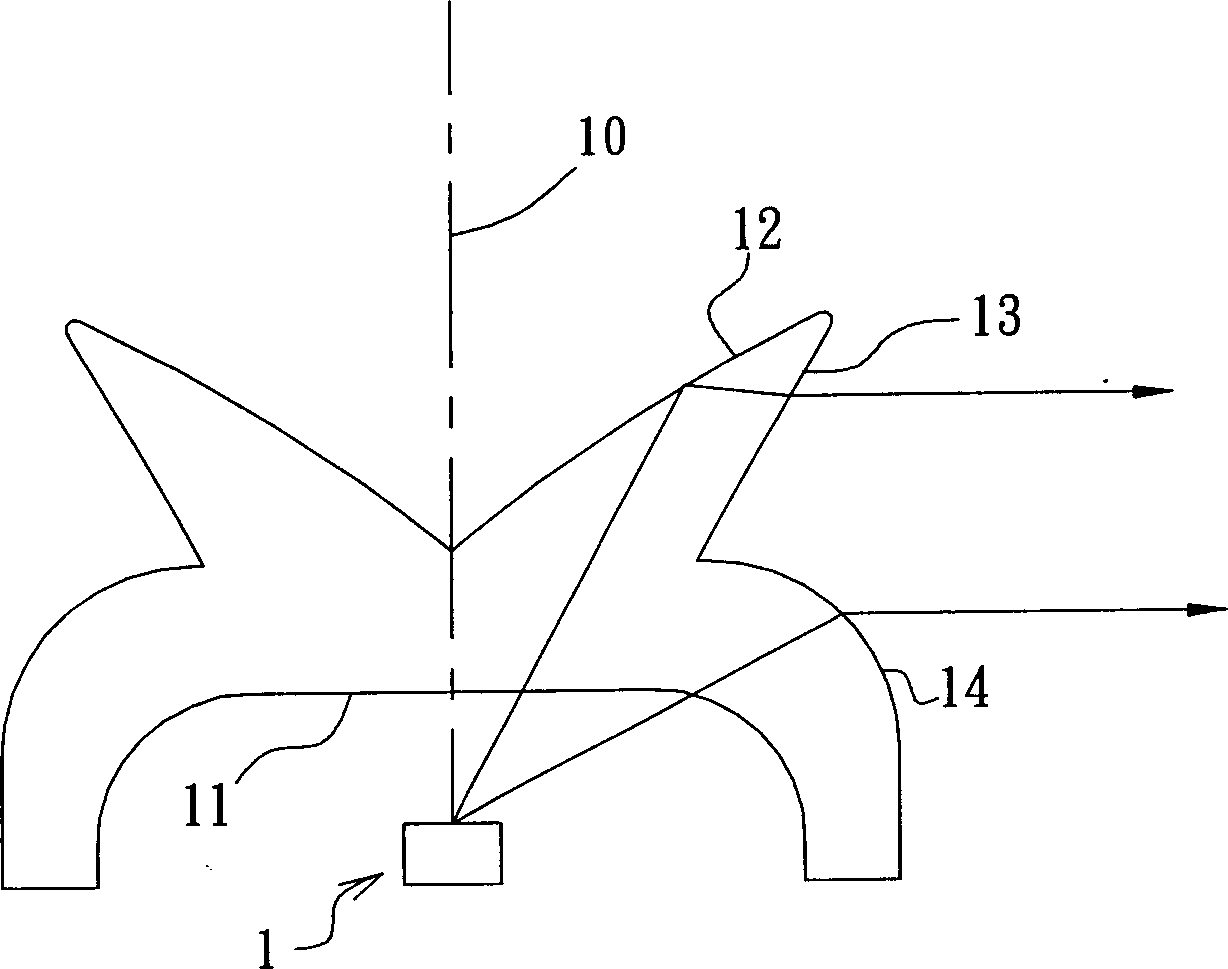

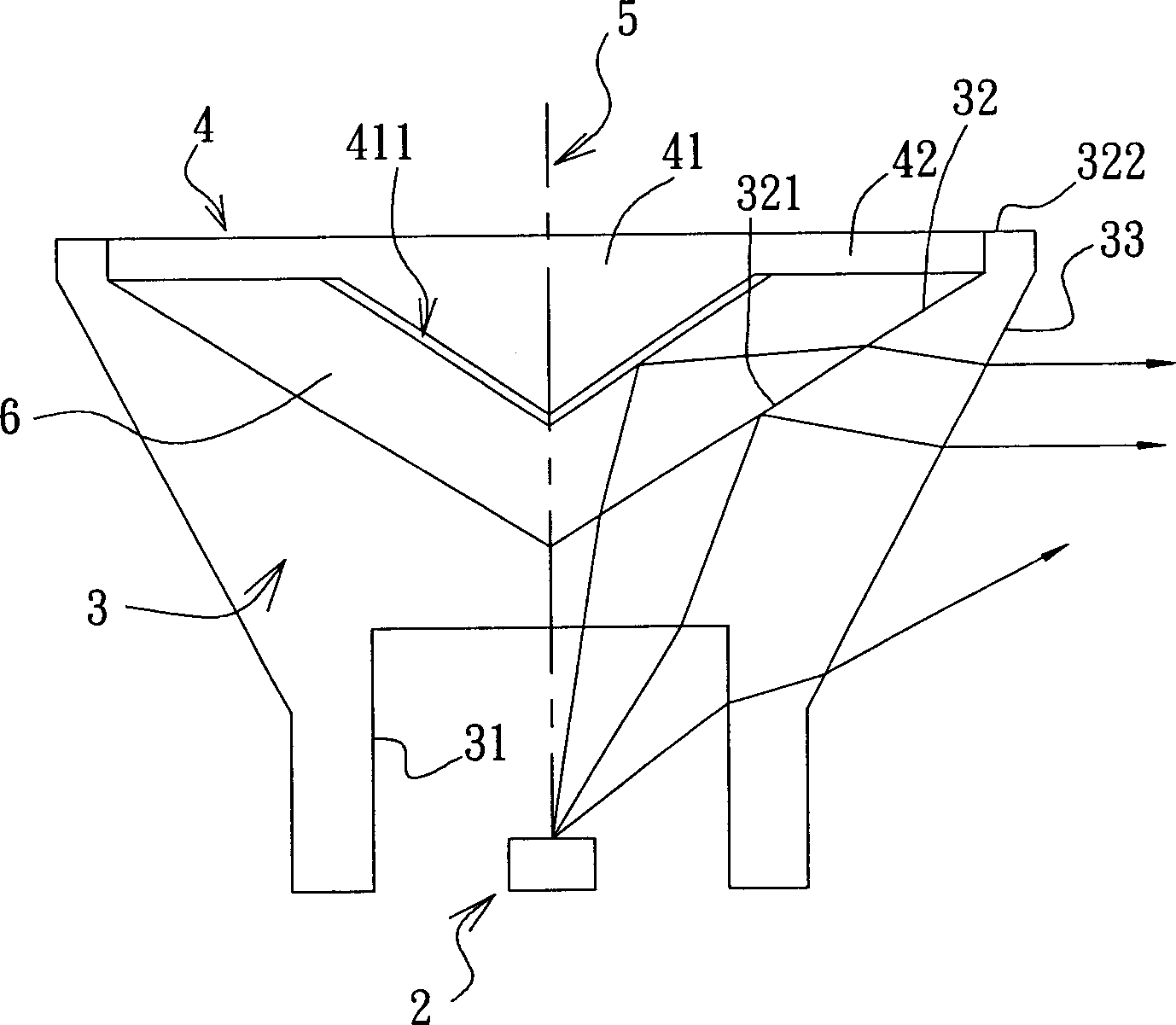

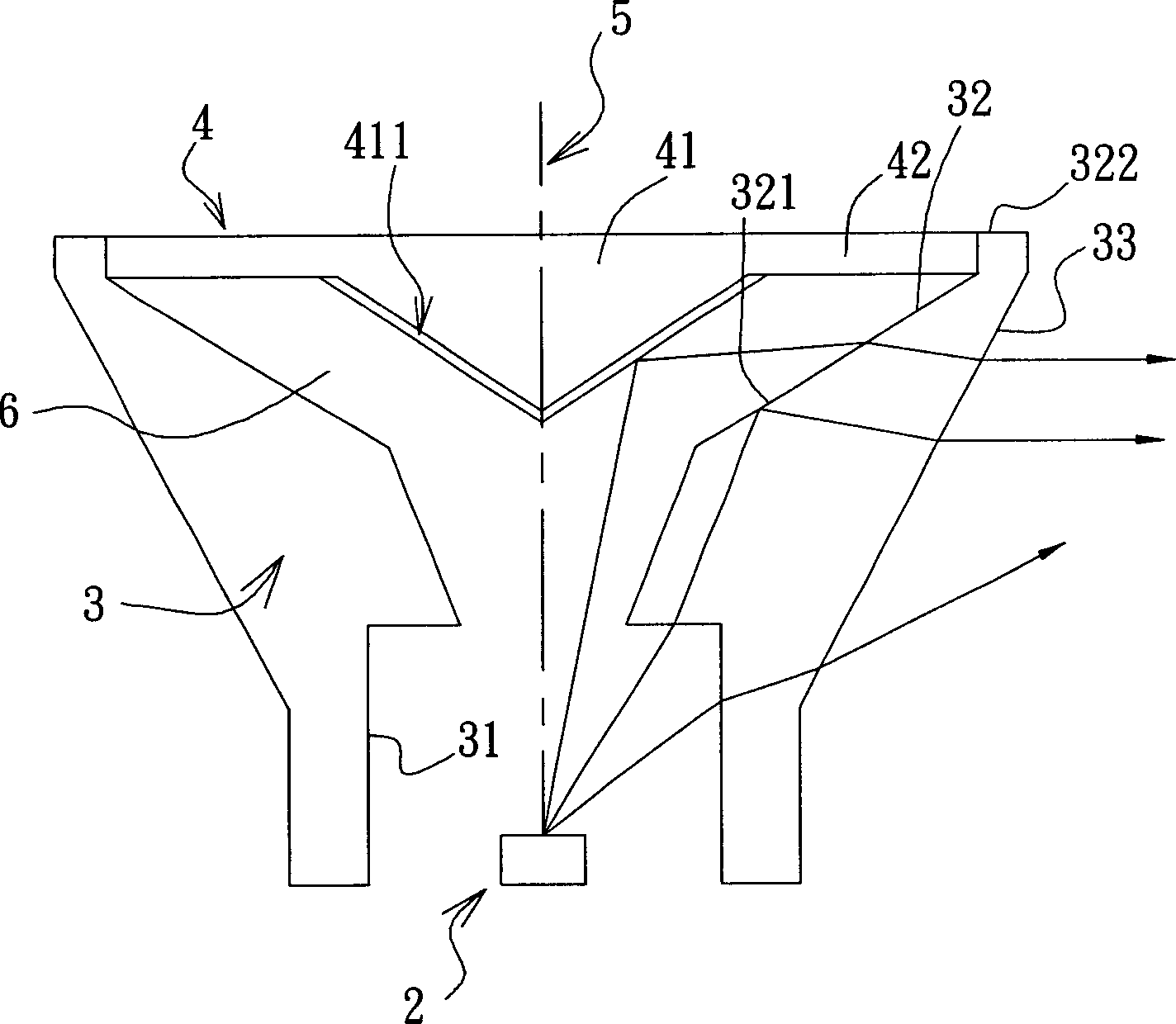

[0022] refer to figure 2 , the first preferred embodiment of the side-illuminated lens group of the present invention is used to guide the light beam emitted by a light-emitting element 2 to emit sideways. In this example, the light-emitting element 2 is illustrated with an LED as an example. A cup body portion 3 and a cover body portion 4 .

[0023] The cup body 3 is a transparent body, and its material includes but not limited to polymethylmethacrylate (polymethylmethacrolate; PMMA) or polycarbonate (polycarbonate; PC). A central axis 5 passing through the LED is defined, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com