Coated forward stub shaft dovetail slot

一种短轴、燕尾的技术,应用在涂层、用于弹性流体的泵送装置的部件、叶片的支承元件等方向,能够解决降低耐腐蚀疲劳性能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

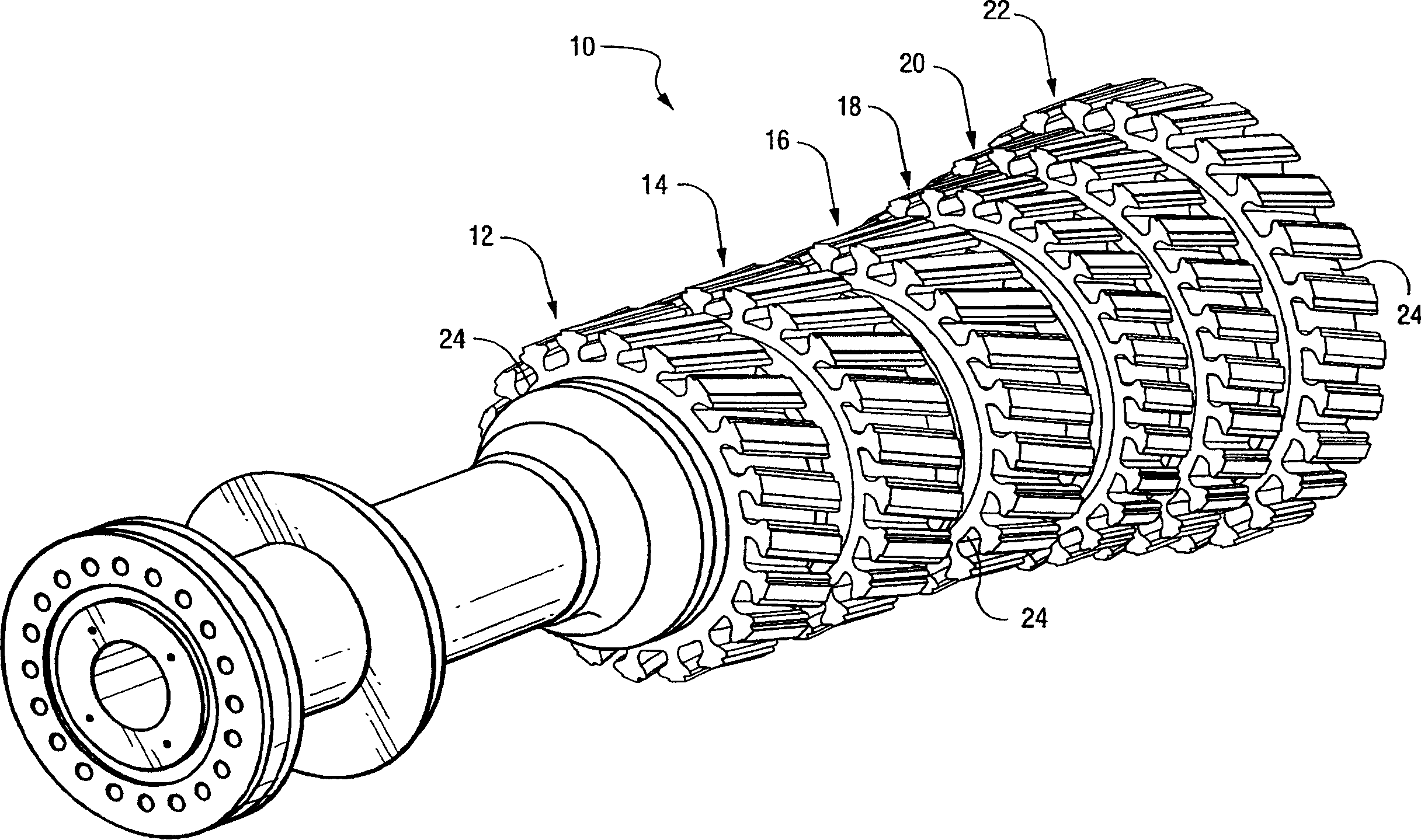

[0013] figure 1 Representing a conventional compressor front stub shaft 10 formed by six integral annular rows of dovetail slots 12, 14, 16, 18, 20 and 22, each slot 24 configured to support a compressor blade with a mating dovetail portion. Each row of blades represents a stage of the short axis of the compressor, and it is the first two rows or stages 12 and 14 of particular interest with respect to the present invention.

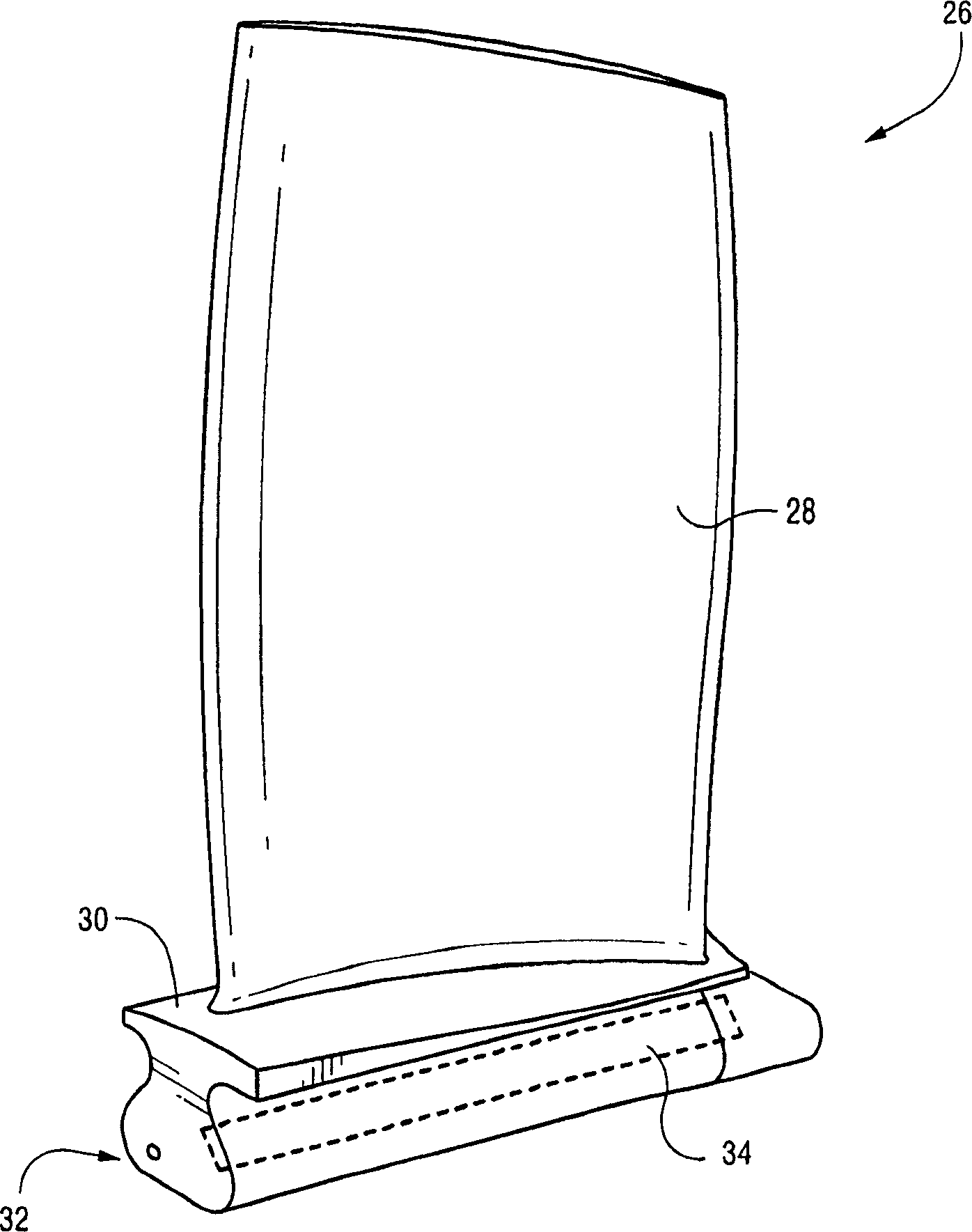

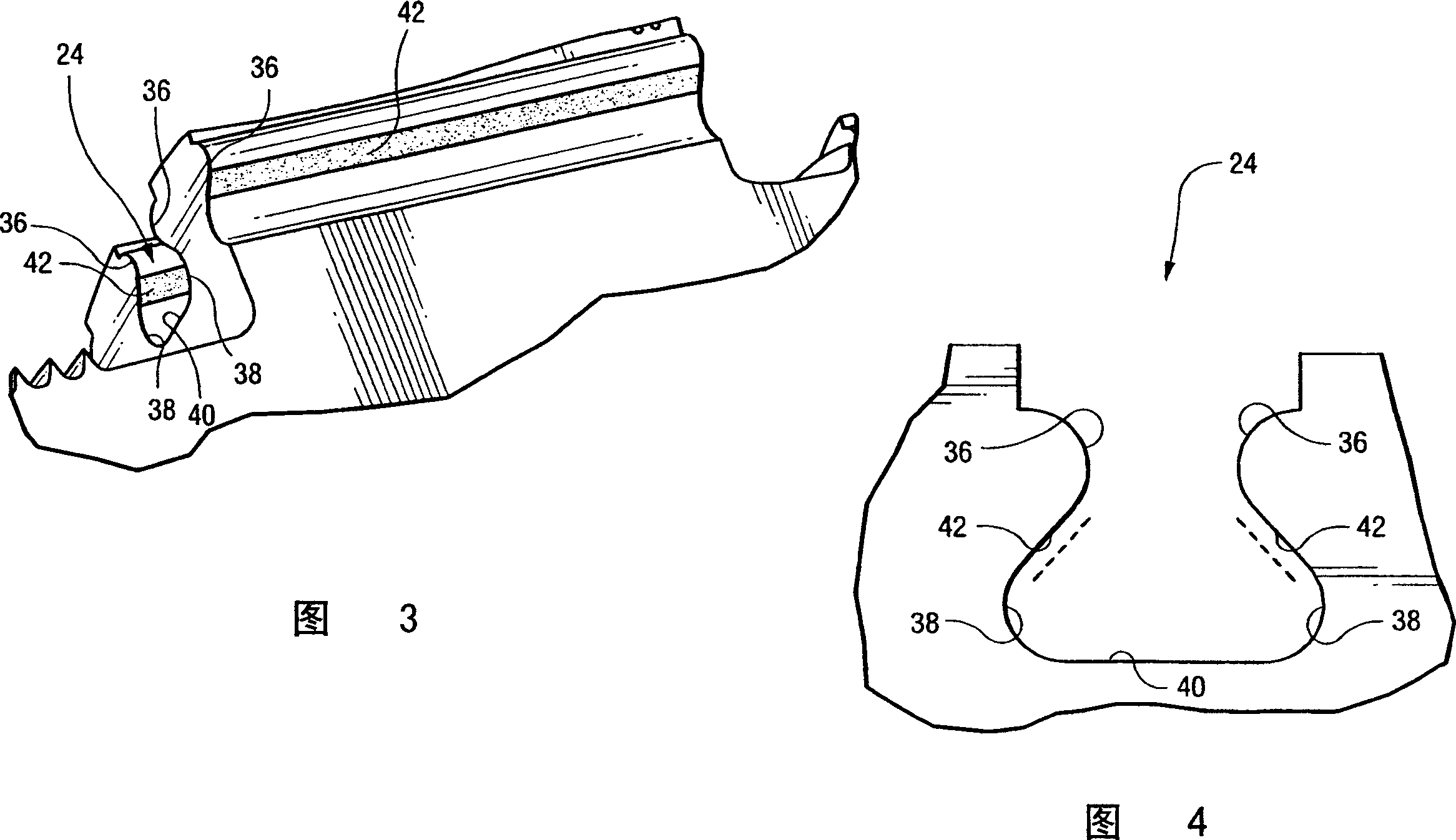

[0014] A typical first stage compressor vane 26 is shown in figure 2 middle. The blade includes an airfoil 28, a platform 30 and is shaped to be received in a corresponding dovetail slot 24 ( figure 1 ) inside the dovetail 32. In the past, wear resistant coatings (shown generally in phantom) have been applied to surfaces 34 (one indicated) on opposite sides of dovetail 32 . But as mentioned above, certain coatings such as Alumazite-ZD are not compatible with the C450 steel alloy material used for the blade 26 . Therefore, the corrosion resistance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com