Process for producing a radiation source, and radiation source

A radiation source and radiation unit technology, applied in the field of radiation sources, can solve problems such as increased production costs of radiation sources, and achieve the effect of shortening the process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

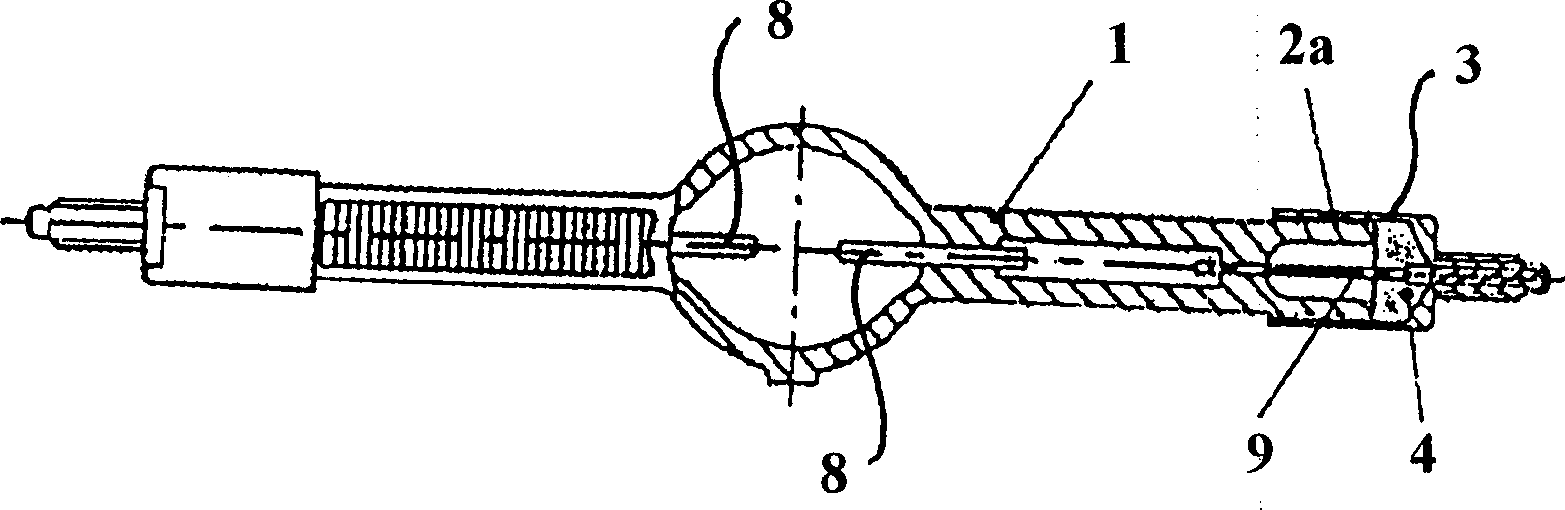

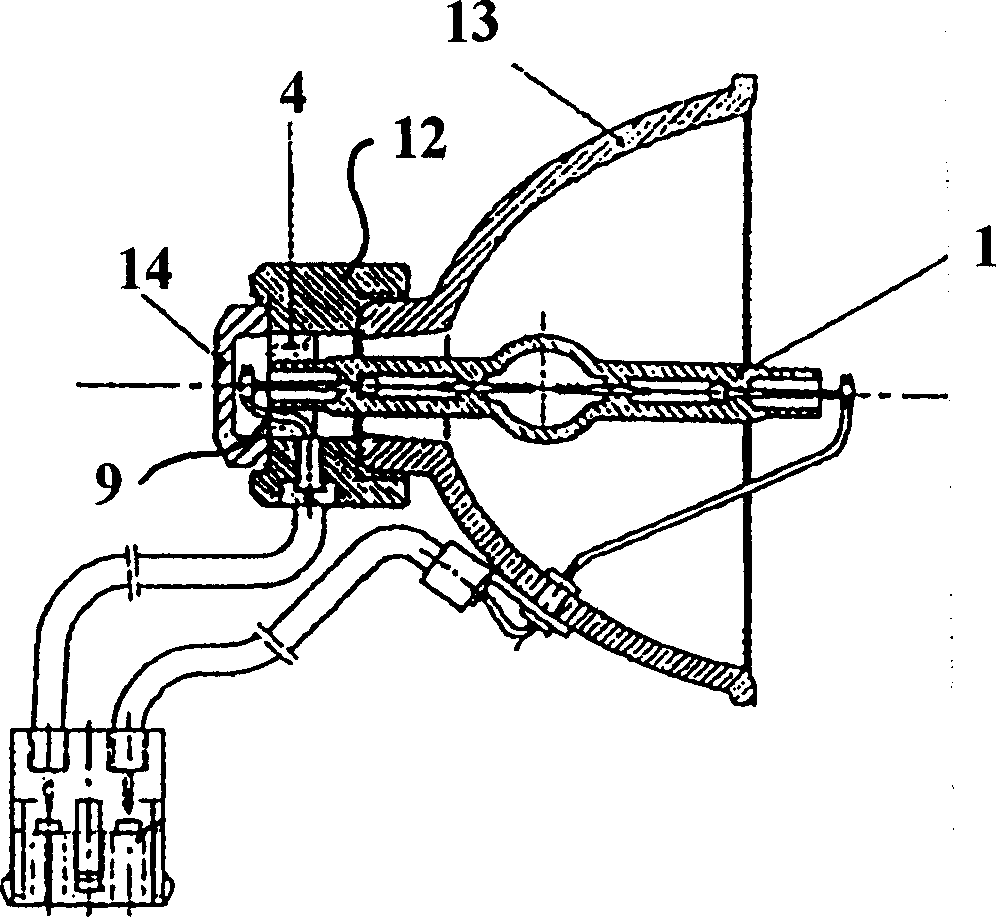

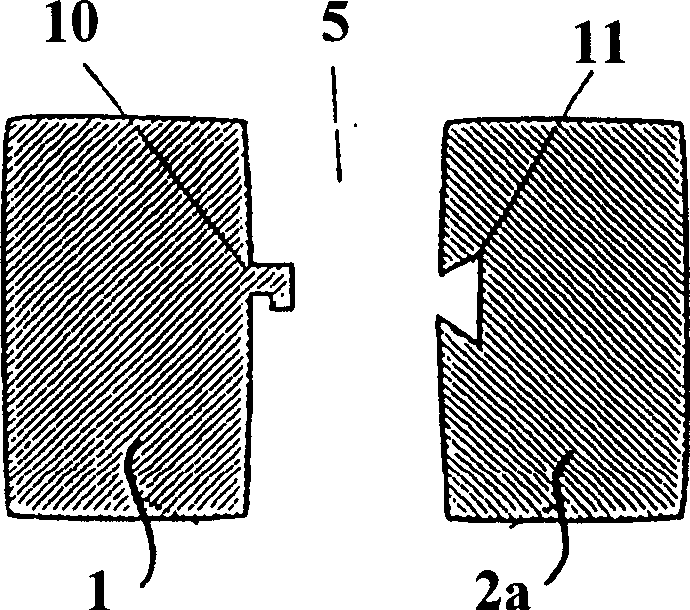

[0048] exist figure 1 The structure of the radiation source according to the invention is shown in the example of a cross-sectional view of a discharge lamp. The discharge lamp comprises a glass or ceramic part 1 in which a radiation element 8 is arranged. In the illustrated embodiment, the radiation elements 8 are two electrodes surrounded by gas. However, it is also conceivable for the radiation unit 8 to be formed, for example, from a coiled filament, or from electrodes in a vacuum.

[0049] The radiation unit 8 is connected to a power supply lead 9 . What is involved in the radiation source 8 shown is a preferably tubular discharge lamp with two opposite ends, so that the current supply leads 9 are also guided in two opposite directions. The discharge lamp shown is provided at each of its ends with a support 2a formed as a metal or ceramic base.

[0050] In the connecting region 3 there is a metal foam 4 which can connect the glass or ceramic part 1 to the support part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com