Camera module

A camera and support member technology, which is applied to cameras, camera bodies, instruments, etc., can solve the problems of long operation time, long hardening time, rising cost, etc., and achieve the effect of increased fixing strength and stable fixing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

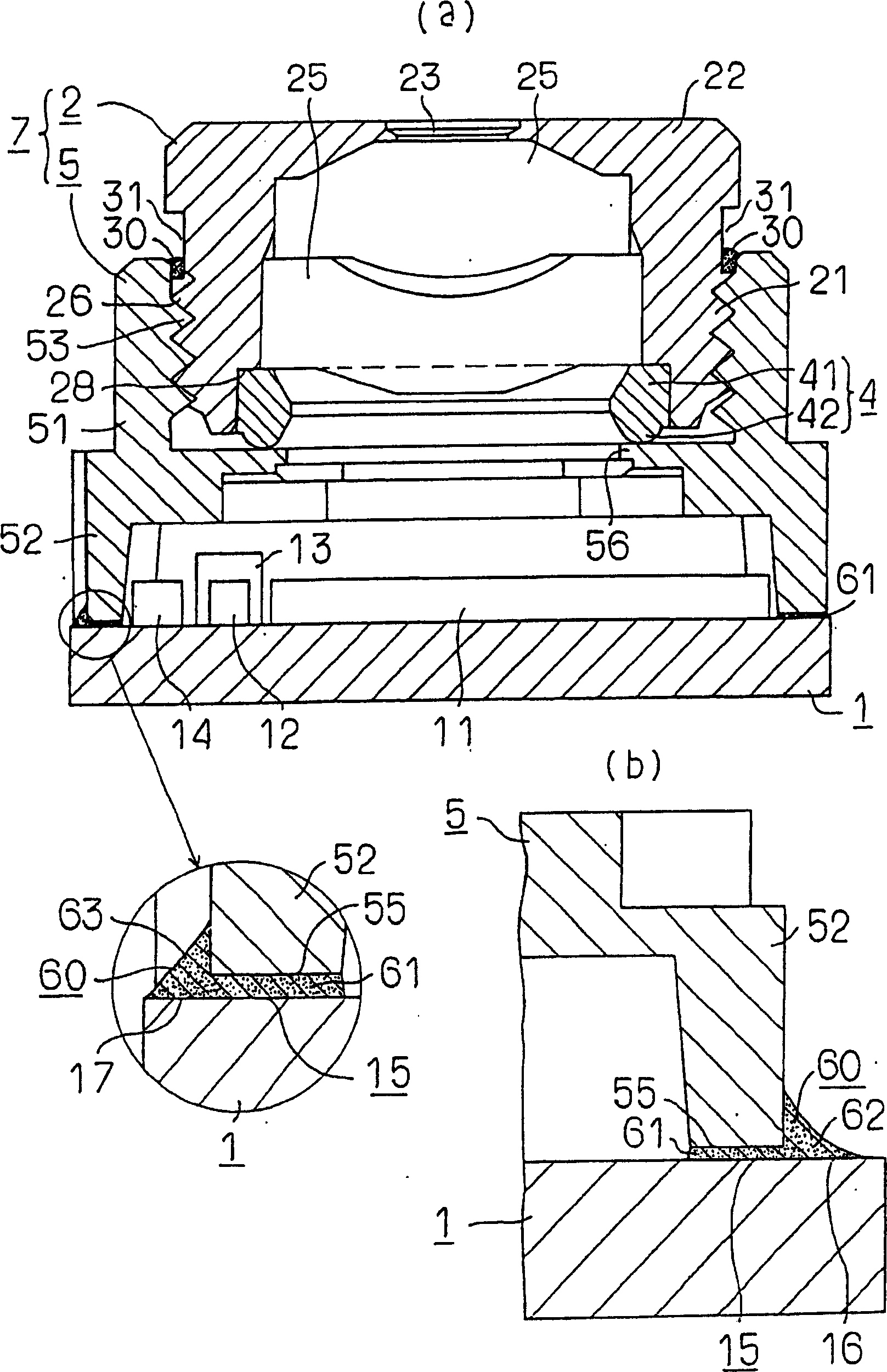

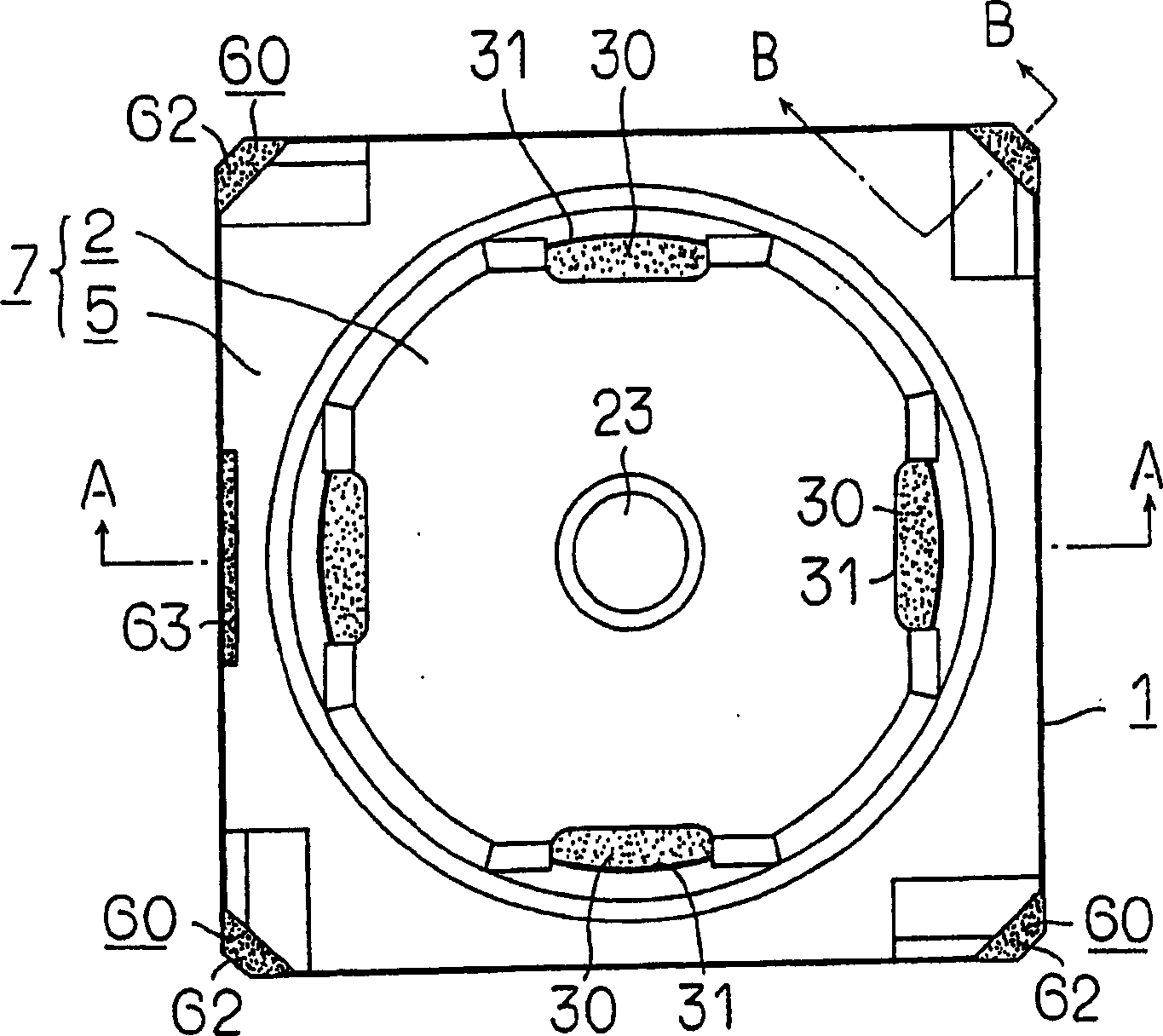

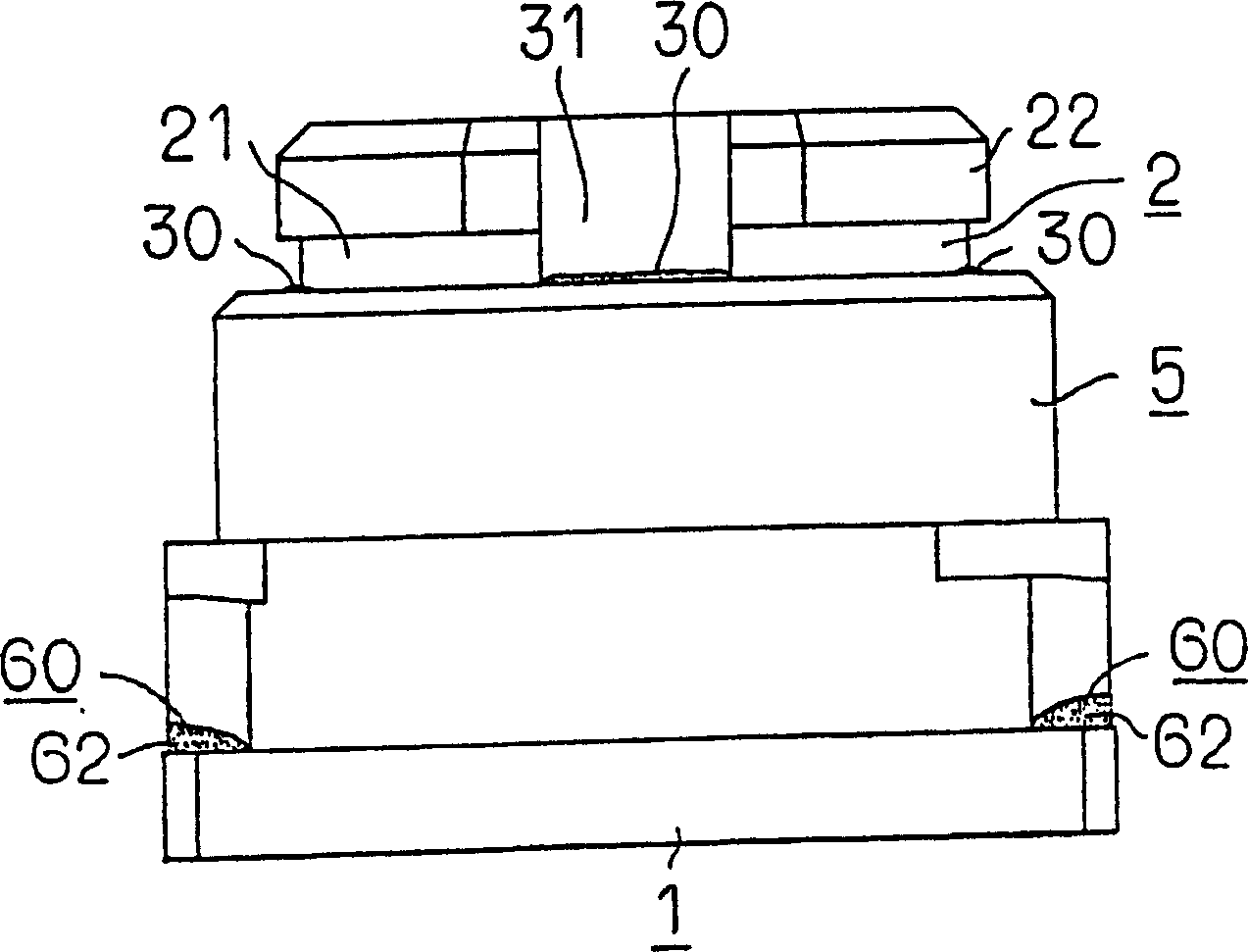

[0032] Figure 1 to Figure 8 An embodiment of the present invention is shown. In these figures, reference numeral 1 is a circuit board (hereinafter referred to as a substrate), reference numeral 2 is a cylinder as an example of a first support member, and reference numeral 4 is an annular elastic body as an example of an elastic member. , Reference numeral 5 is a base as an example of the second supporting member.

[0033] The cylinder 2 and the base 5 support the lenses 25 , 25 and form a support member 7 fixed on the substrate 1 .

[0034] Substrate 1 as Figure 7 As shown in (b), it is formed into a substantially square plate shape with synthetic resin, and is formed into a shape with four corners cut off.

[0035] In the upper central part of the substrate 1, such as figure 1 As shown in (a), the imaging element 11 and other circuit elements 12 to 14, etc., which are electrically connected by a wiring pattern (not shown), are arranged, and external connections are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com