Microwave heating available vacuum-packed bag, and fabricating method

A technology of microwave heating and packaging bags, which is applied to packaging under vacuum/special atmosphere, envelope/bag manufacturing machinery, rigid/semi-rigid container manufacturing, etc. The effect of dry and hard food, convenient for home use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

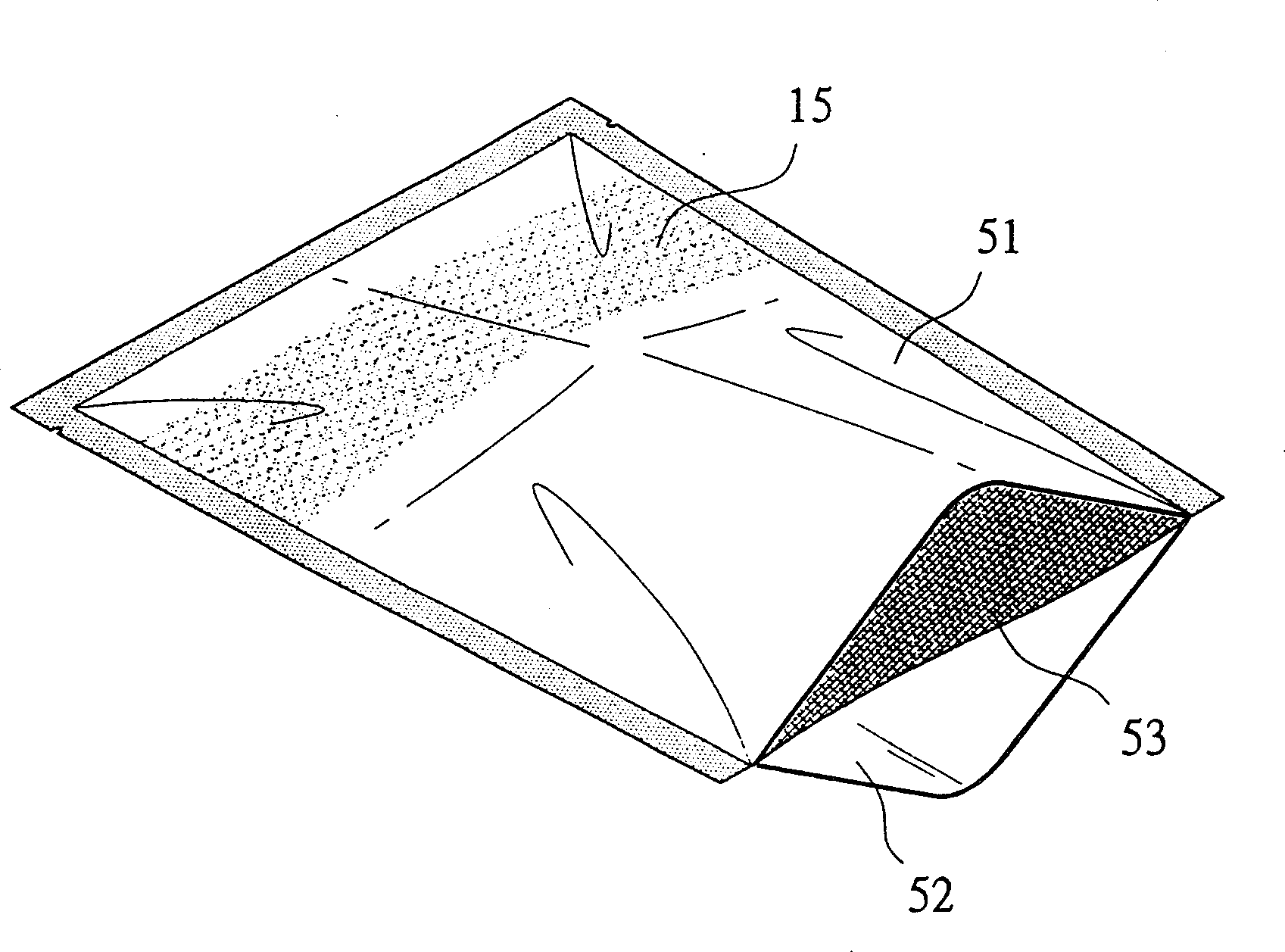

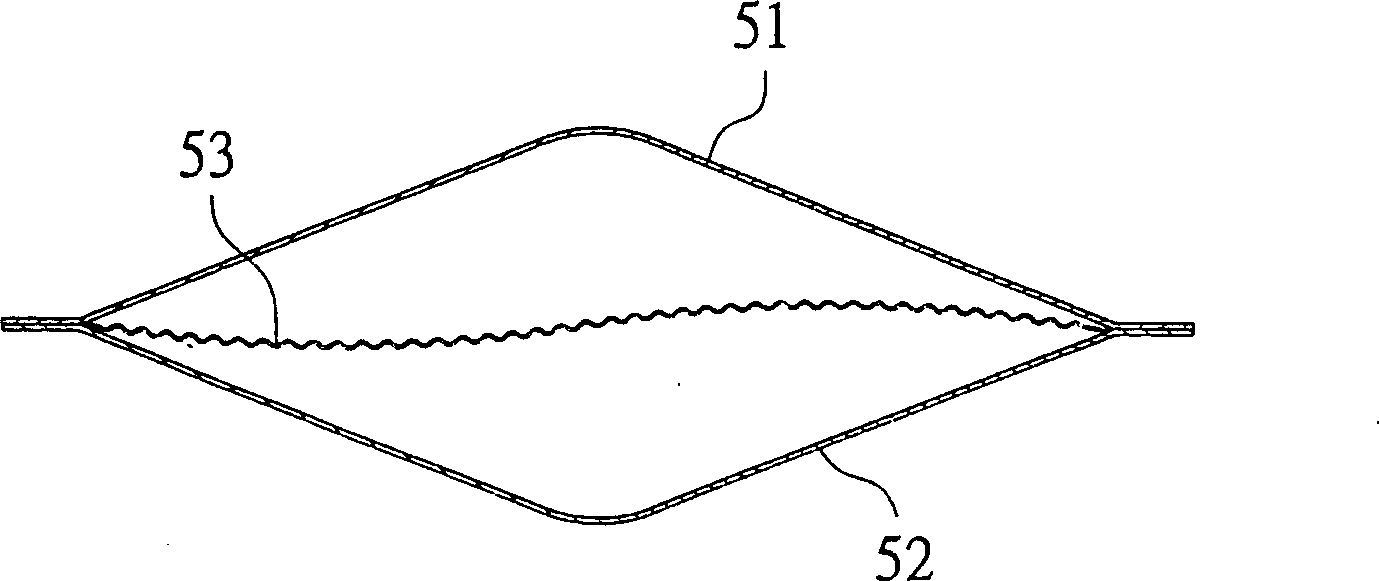

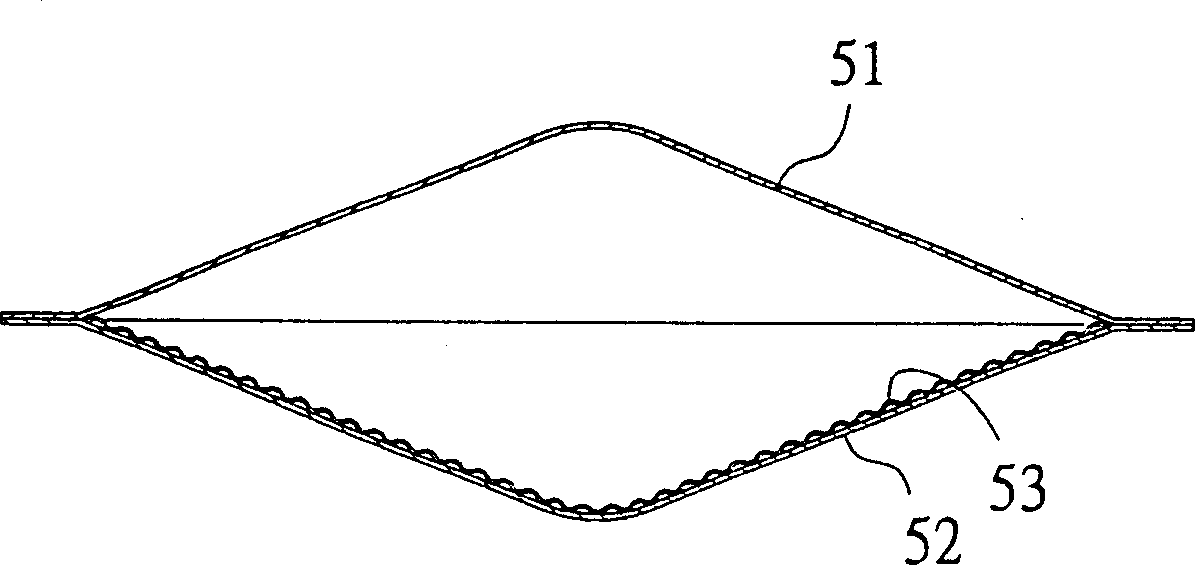

[0032] Microwave heatable vacuum packaging bag provided by the present invention, such as Figure 1 to Figure 6 As shown, it at least includes a first film layer 51 , a second film layer 52 and an air guide layer 53 . The air guide layer 53 is interposed between the first film layer 51 and the second film layer 52 , and can also be directly combined with the first film layer 51 or the second film layer 52 . The first film layer 51 and the second film layer 52 are respectively provided with heat-resistant layers 511 , 522 and heat-sealing layers 512 , 521 . A plurality of essentially airtight microscopic gap structures 15 can also be set on the first film layer 51 or the second film layer 52, which has the following two manufacturing methods:

[0033] The first method, such as Figure 7As shown, a first film layer 51 without a microscopic gap structure 15 or an inner edge of a second film layer 52 is combined with an air-conducting layer 53 by thermal bonding and pressing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com