Food processor

A food processor and food processing technology, which is applied in the direction of household machinery, household appliances, and applications for filtering food, can solve the problems of large starting torque, large motor noise, single rotation speed, etc., and achieves convenient home use, simple and reasonable structure. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

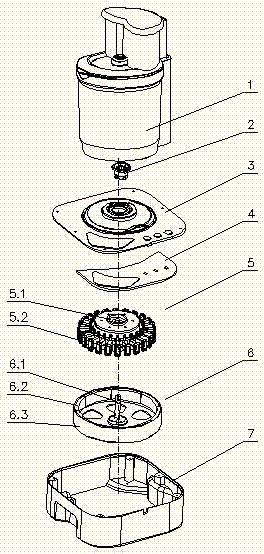

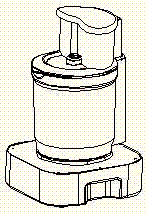

[0034] see Figure 1-Figure 4 , The food processor includes a food container 1 arranged on the host, the motor inside the host is connected to the food processing appliance inside the food container 1 through a connector 2, and the motor is a three-phase induction synchronous motor.

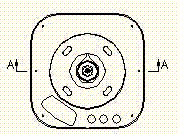

[0035] In this embodiment, the motor includes a motor inner stator 5 and a motor outer rotor 6, the motor inner stator 5 is fixed on the main machine, the motor outer rotor 6 is sleeved outside the motor inner stator 5 and rotates around the motor inner stator 5, the motor The outer rotor 6 includes a magnet 6.2 embedded in a bracket 6.3, and an output shaft 6.1 is arranged in the middle of the bracket 6.3, and one end of the output shaft 6.1 is connected with the connector 2.

[0036] The food processing appliance, the connector 2 and the output shaft 6.1 are arranged co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com