Method and apparatus for detecting the parameter of liquid state metal in a container

A technology of liquid metal and measuring method, applied in the direction of measuring device, configuration of indicating equipment/measuring equipment, metal processing equipment, etc., can solve the problem that reliable scale cannot be obtained at the same time, and the height of molten metal and the depth of mold powder cannot be synchronized. , reliable detection, reliable calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] While the present invention is explained by reference to the embodiments described in the following detailed description and illustrated drawings, it is to be understood that the following detailed description and drawings are not intended to limit the invention to the particular illustrative disclosure. Rather, the illustrative embodiments described are merely illustrative of the features of the invention, the scope of which is defined by the appended claims.

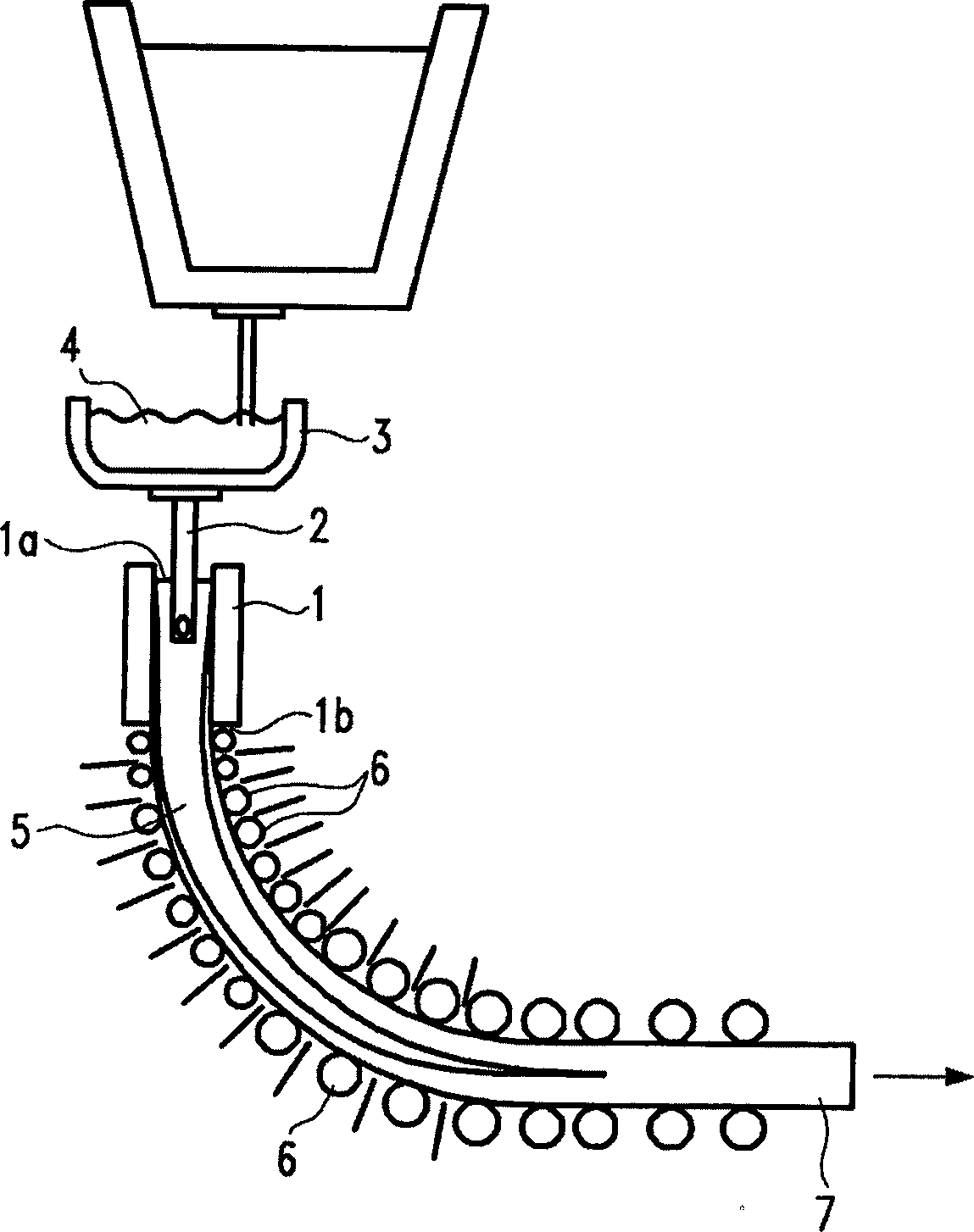

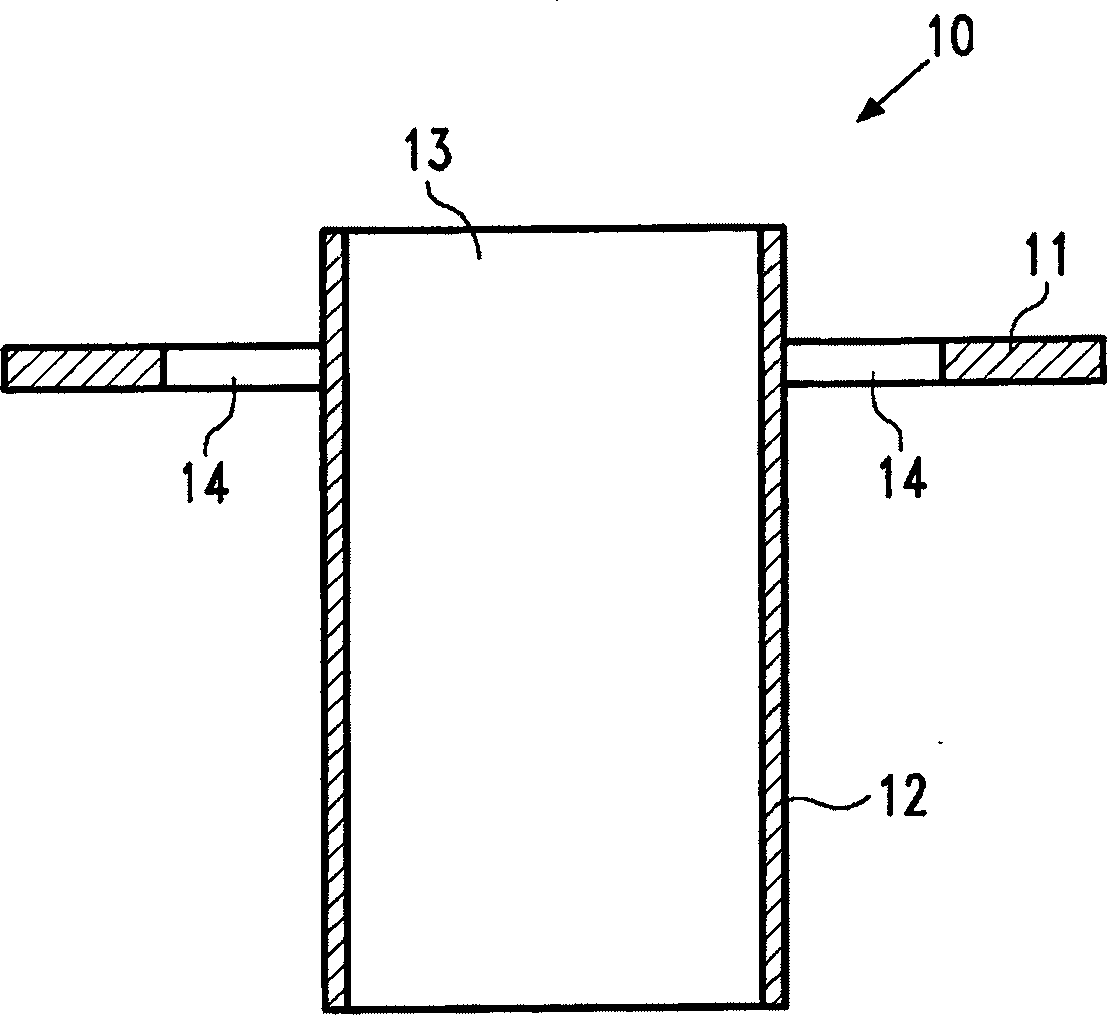

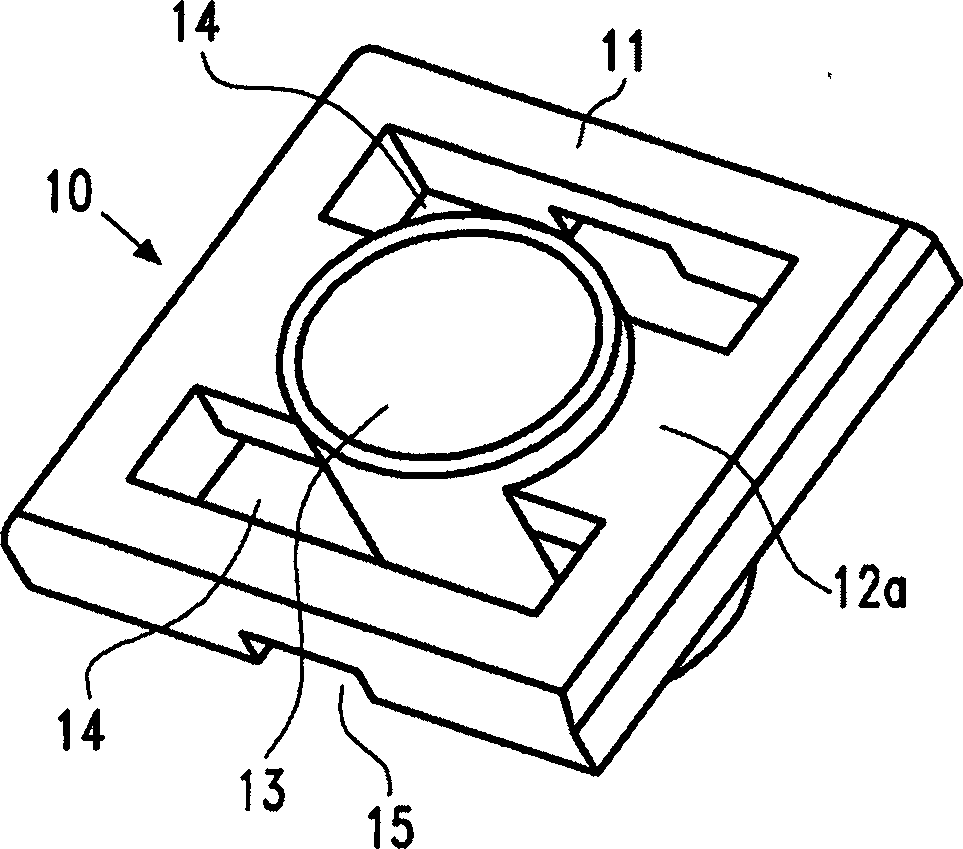

[0034] As is evident from the disclosure given above, it will be appreciated that the present invention is particularly advantageous when used to detect and / or measure the depth of mold powder and the level of molten metal in a mold during continuous moulding. For this reason, several examples will be given below in which corresponding embodiments of the method and apparatus according to the invention are applied in continuous casting processes and continuous casting installations and for measuring the depth of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com