Gear shifting motor

A technology for shifting motors and components, which is applied to electromechanical devices, electrical components, and electric components, etc., can solve the problems of large impact force, incompatibility, and inability to accurately calculate the motor shaft speed, and achieve the effect of accurate shifting and safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

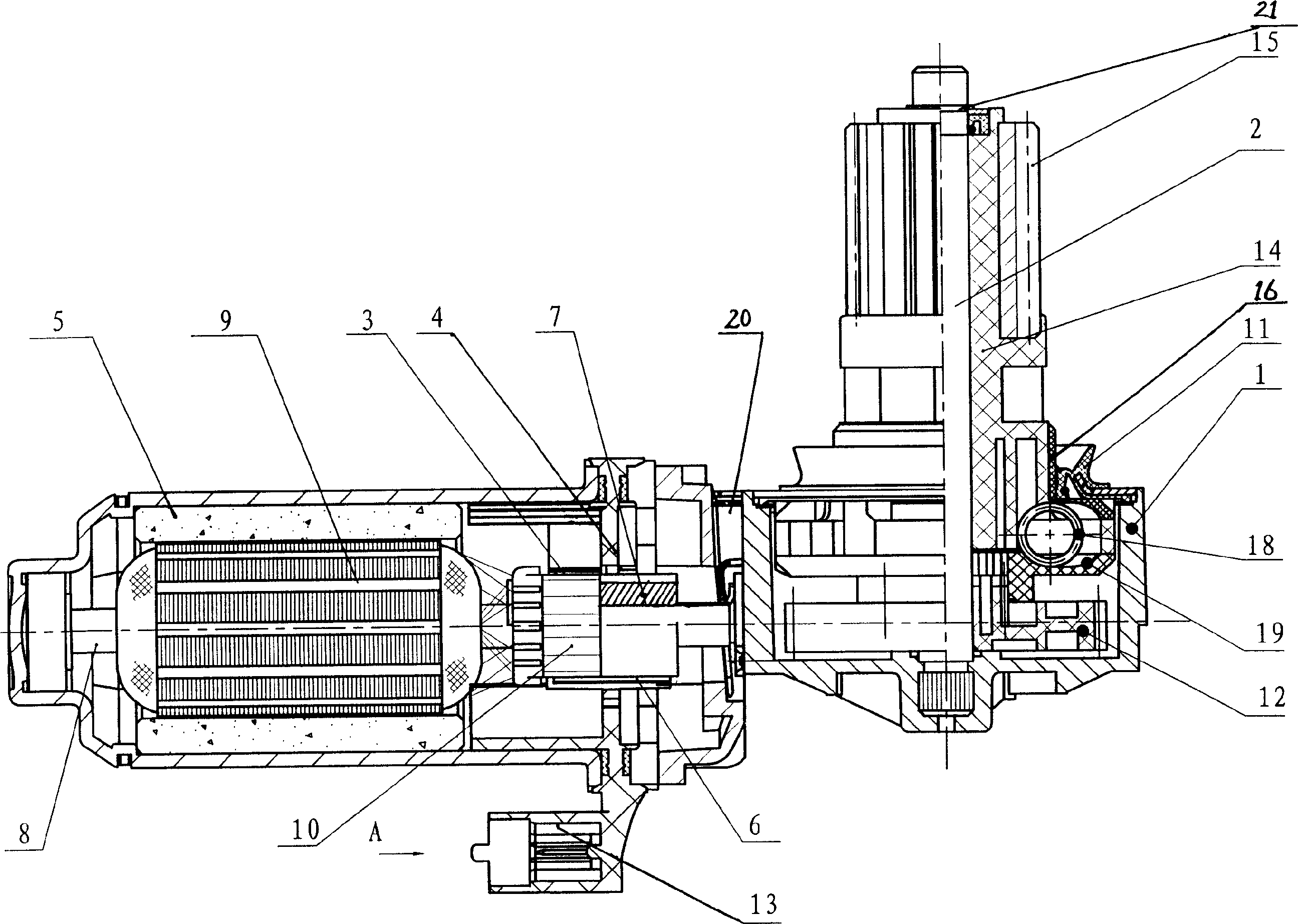

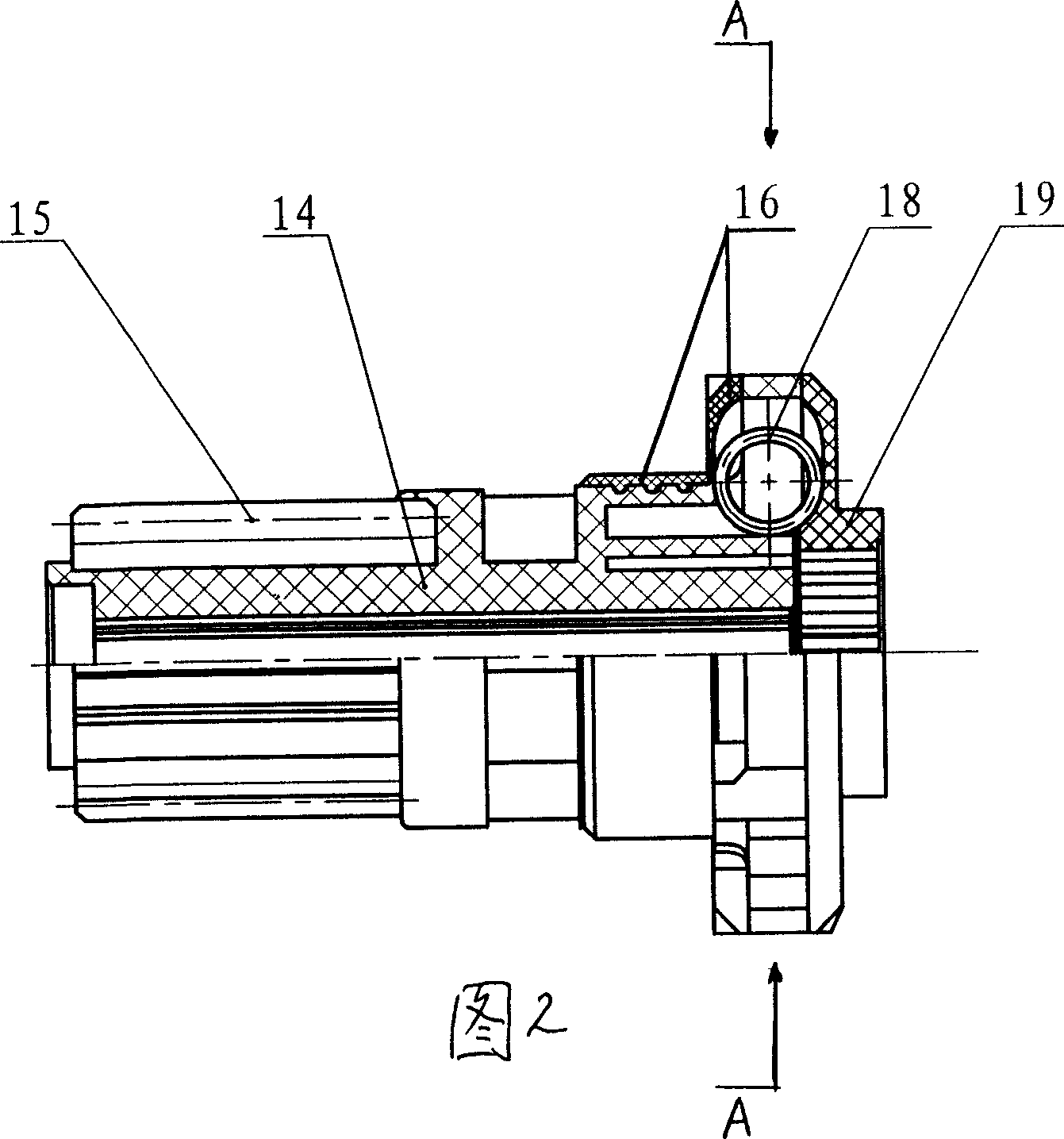

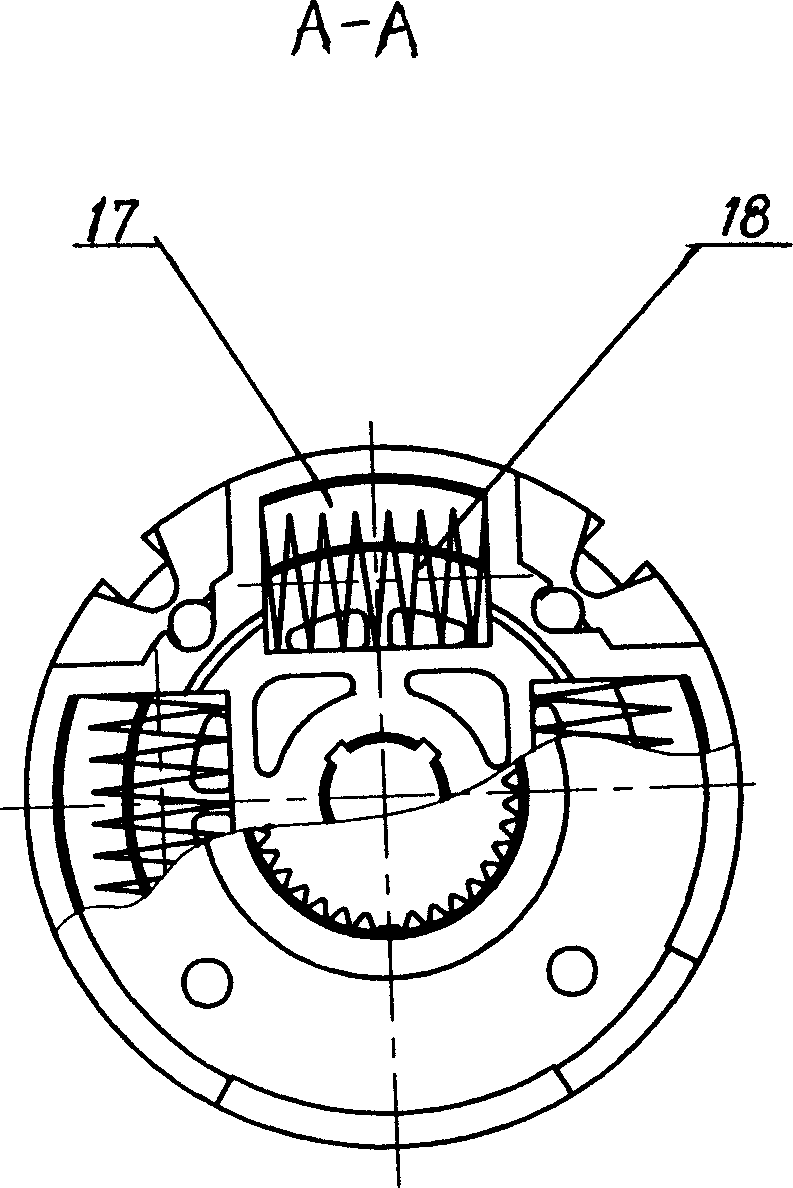

[0012] refer to Figure 1 to Figure 4 It can be seen that the shift motor of the present invention includes a reducer housing assembly, a brush holder assembly, a rotor assembly, a stator assembly 5, a driving gear 12, a gear cover assembly 11, a plug connector 13, and a blocking cover assembly 20, wherein the reducer housing The assembly includes a reducer housing 1 and a gear shaft 2. The brush holder assembly includes a brush 3 and a brush holder 4. The rotor assembly includes a motor shaft 8, a rotor winding 9, and a commutator 10. The brush holder assembly includes Magnetic Hall inductor 6 (permanent magnet is housed on its circuit board) is housed on frame 4, and the wiring of this Hall inductor 6 is located in plug connector 13, on the motor shaft 8 of described rotor assembly, Corresponding to the position of the magnetic Hall sensor, there is an induction counting gear 7 (the uniformity of the magnetic pole angle is high, and the material is pure electric iron); the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com