Electronic park brake valve system for air brakes vehicles

A parking brake cylinder, vehicle braking technology, applied in the direction of brake transmission, brakes, brake components, etc., can solve the problems of difficult installation, increased parking brake release time, occupying space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

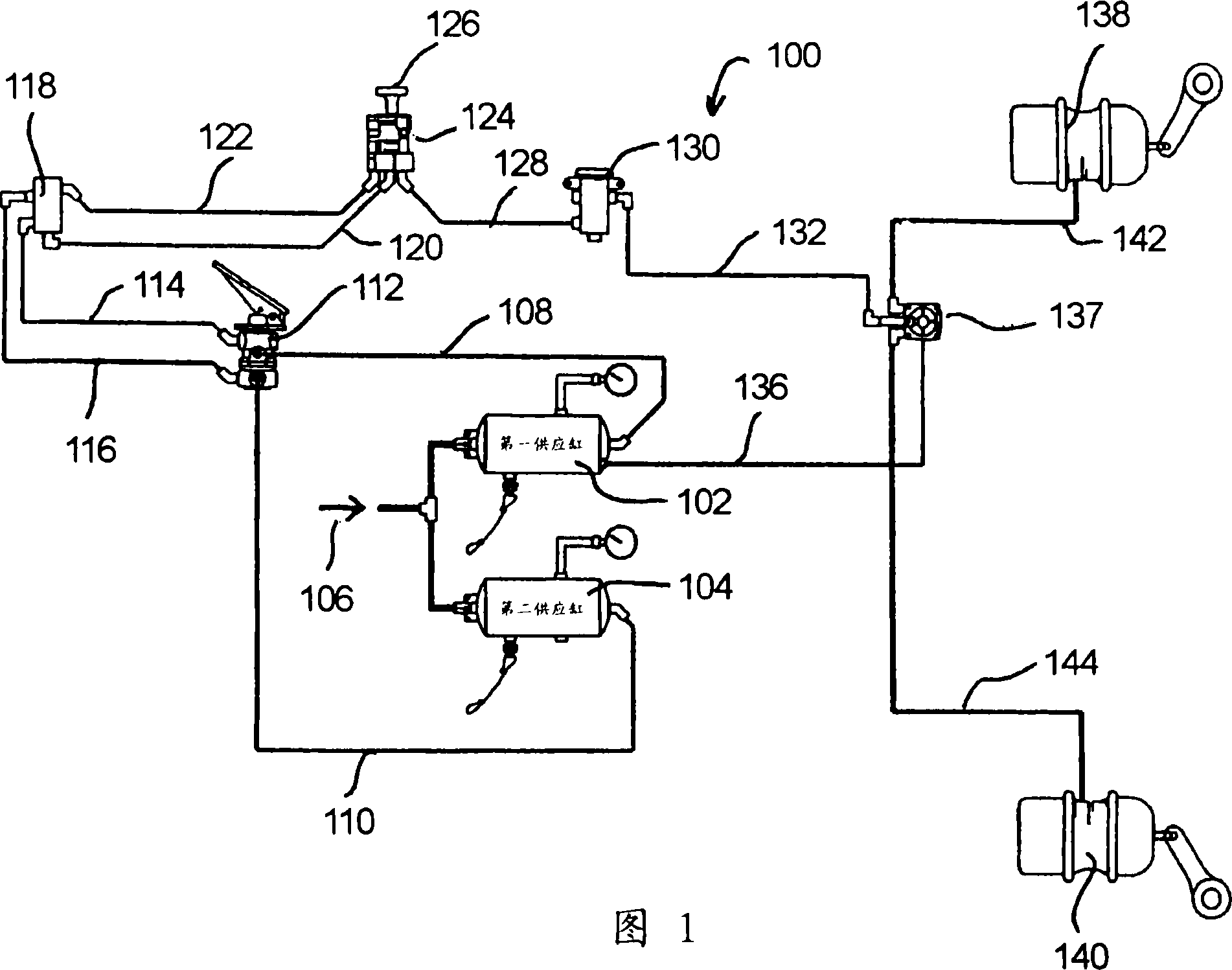

[0024]As shown in FIG. 1 , a typical heavy vehicle pneumatic braking system 100 in the prior art is shown. The system 100 includes a primary compressed air supply cylinder 102, a secondary compressed air supply cylinder 104, both of which receive compressed air from a compressed air source (shown by arrow 106), typically a compressor. The primary compressed air supply cylinder 102 and the secondary compressed air supply cylinder 104 are connected by conduits 108, 110 to a brake pedal 112, which is located within the cab, generally within easy reach of the driver's feet.

[0025] The brake pedal 112 is connected by conduits 114, 116 to a manifold 118 which is connected by conduits 120, 122 to a push / pull dual check valve (PPDC) 124 which typically includes a push / pull handle 126 located in the cab, This handle is normally located on the bulkhead within the driver's reach. PPDC valve 124 is connected by conduit 128 to switch valve 130 which is connected by conduit 132 to relay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com