Short-length reduced-pressure backflow preventor

A backflow prevention and angle technology, applied in the field of low-pressure backflow preventer valve assemblies, can solve the problems of high backflow preventer assembly manufacturing, assembly, maintenance and repair costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

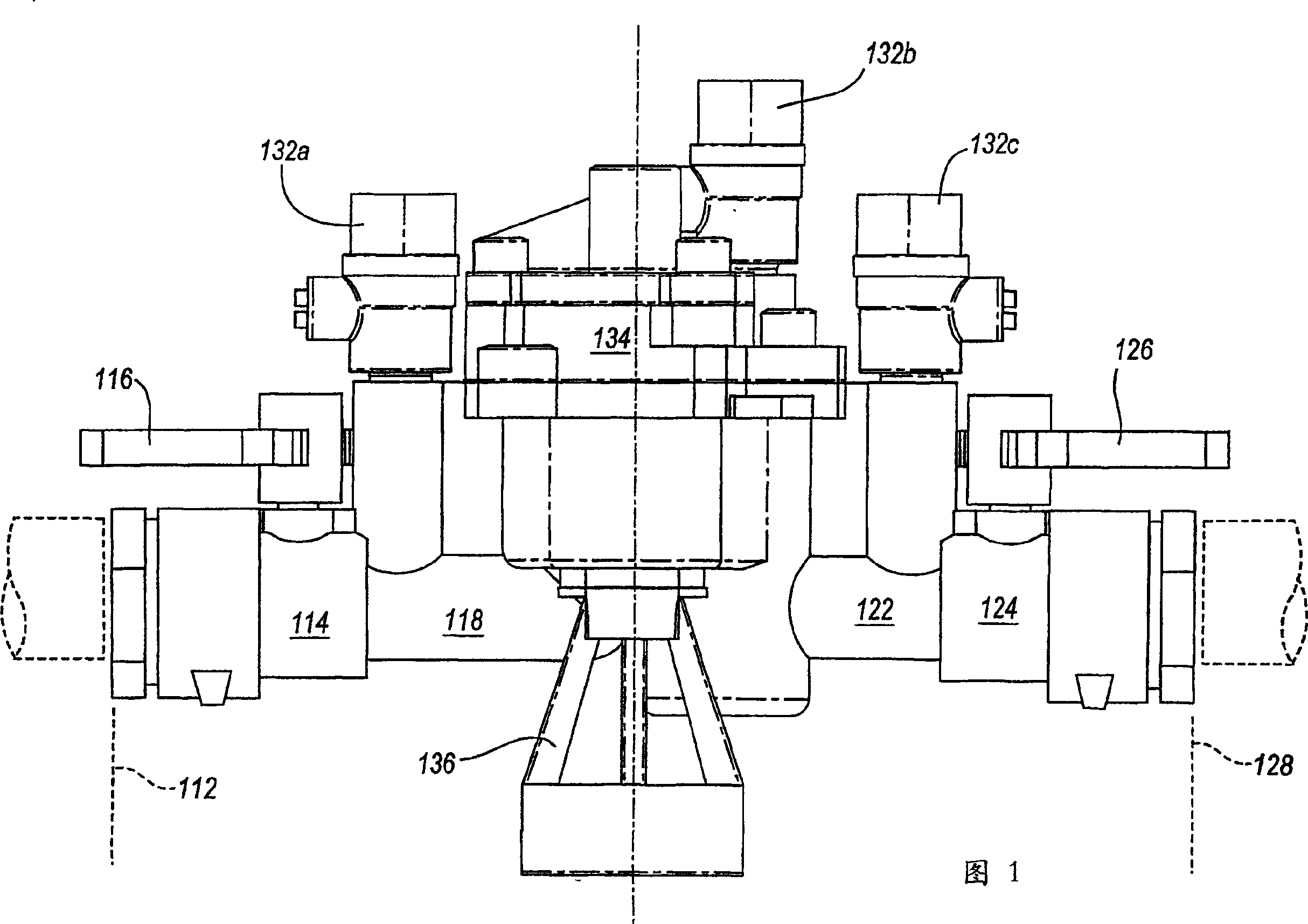

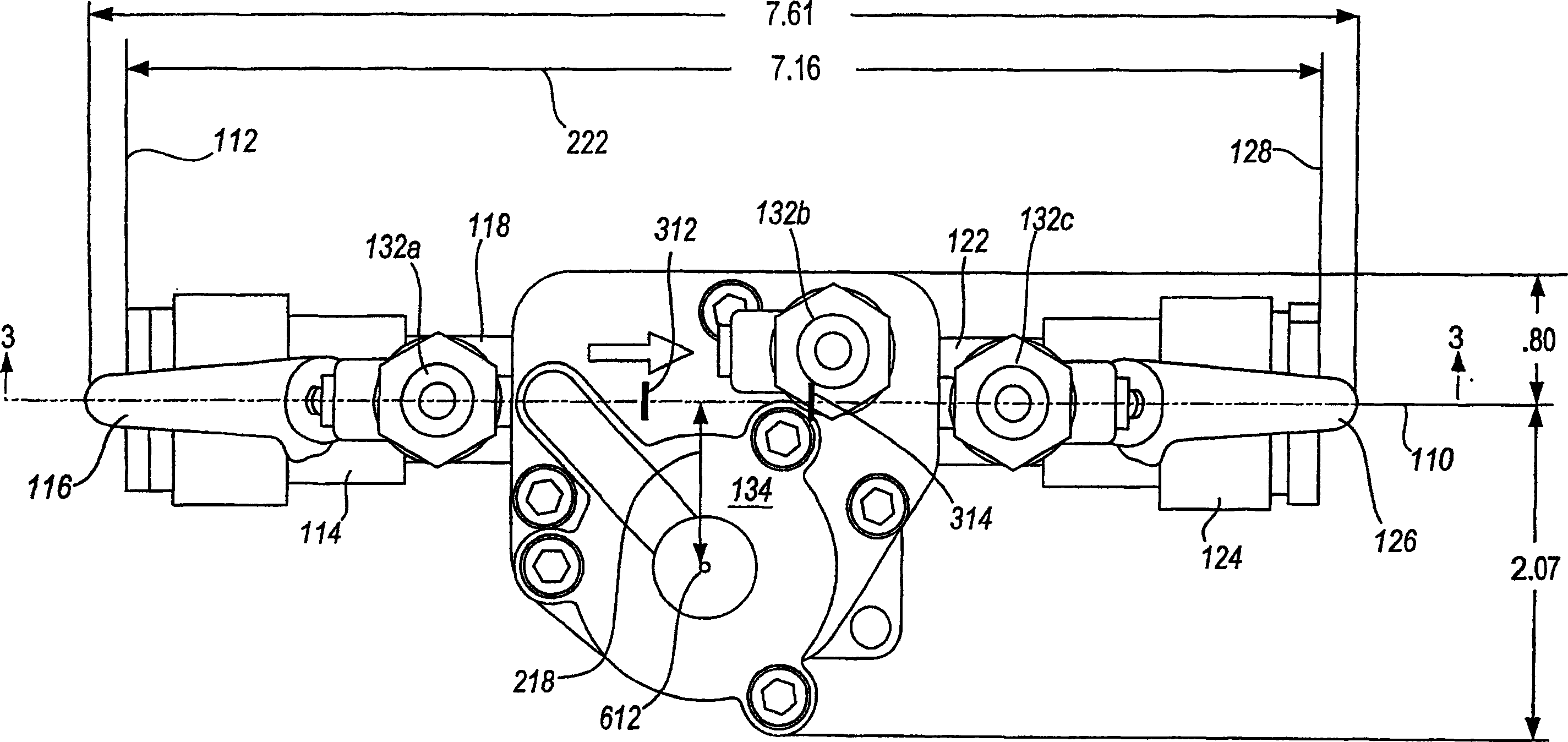

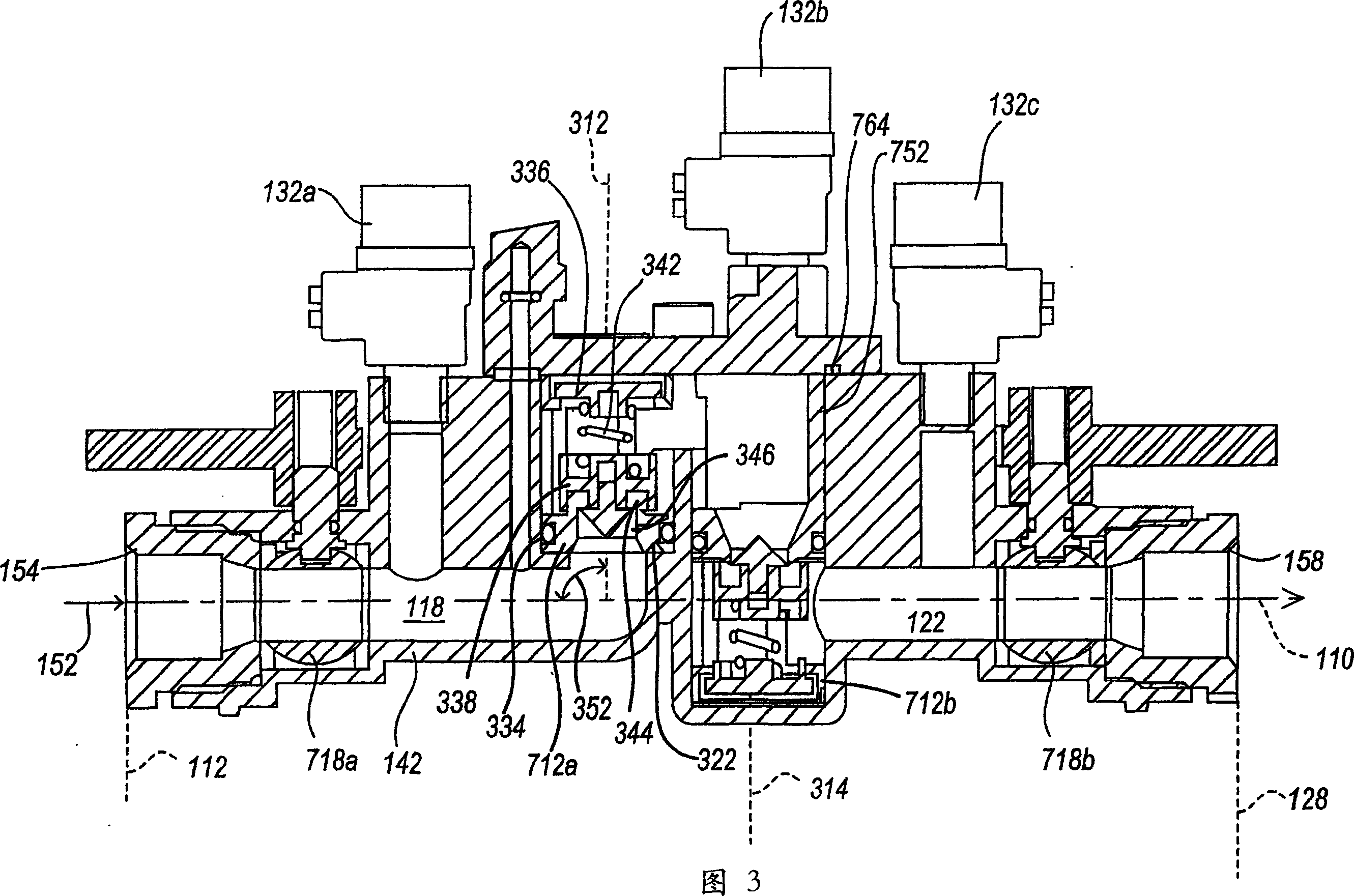

[0021] In the embodiment depicted in FIG. 1 , the input orifice forming an input orifice plane 112 is in fluid communication with a first shutoff valve body 114 controlled by a handle or lever 116 . Valve body conduit 118 provides fluid passage to a first check valve having a first check valve travel axis 312 (FIG. 3). The first check valve can be moved from the closed valve configuration shown in Figure 3 to the Figure 4 The normal open (that is, open during normal use) state among them. Liquid therethrough flows in a lateral direction 412 to a second check valve forming a second check valve axis 314 . Liquid flows through the second check valve and to a second conduit 122, which leads to a second shut-off valve body 124 controlled by a second lever or handle 126 whereby the liquid flow can pass through a plane 128 forming an output orifice. out of the output orifice. The test cocks 132a, b, c may be used for calibration, maintenance purposes and others. A relief valve m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com