Big flow magnetic check valve

A large flow, check valve technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of inconvenient cleaning and disassembly, hanging debris on the bracket, and large water resistance, etc., to achieve disassembly and assembly Easy construction, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

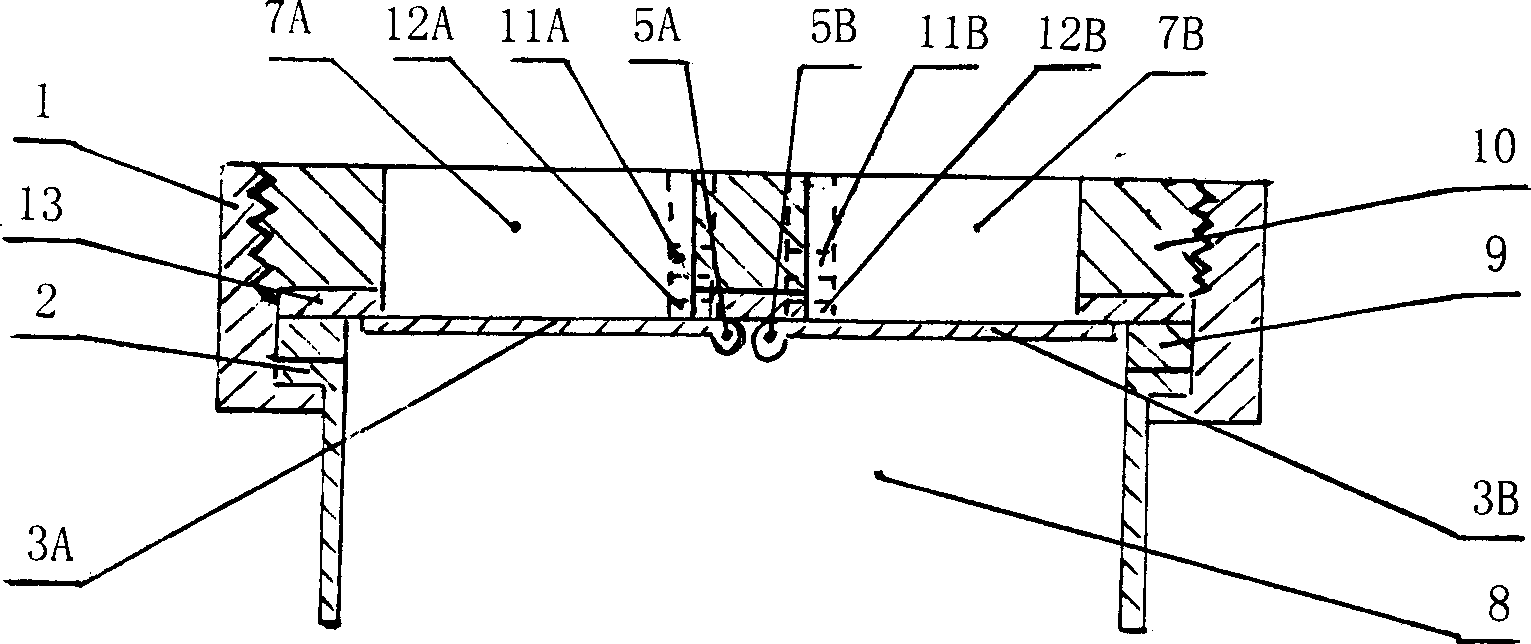

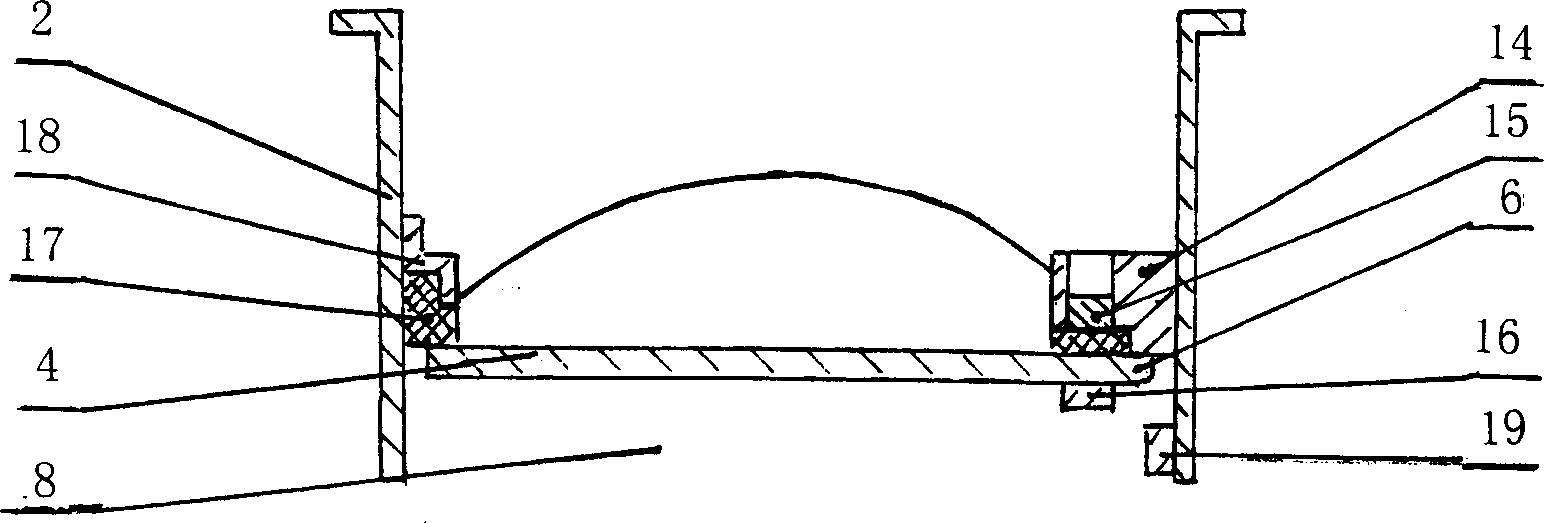

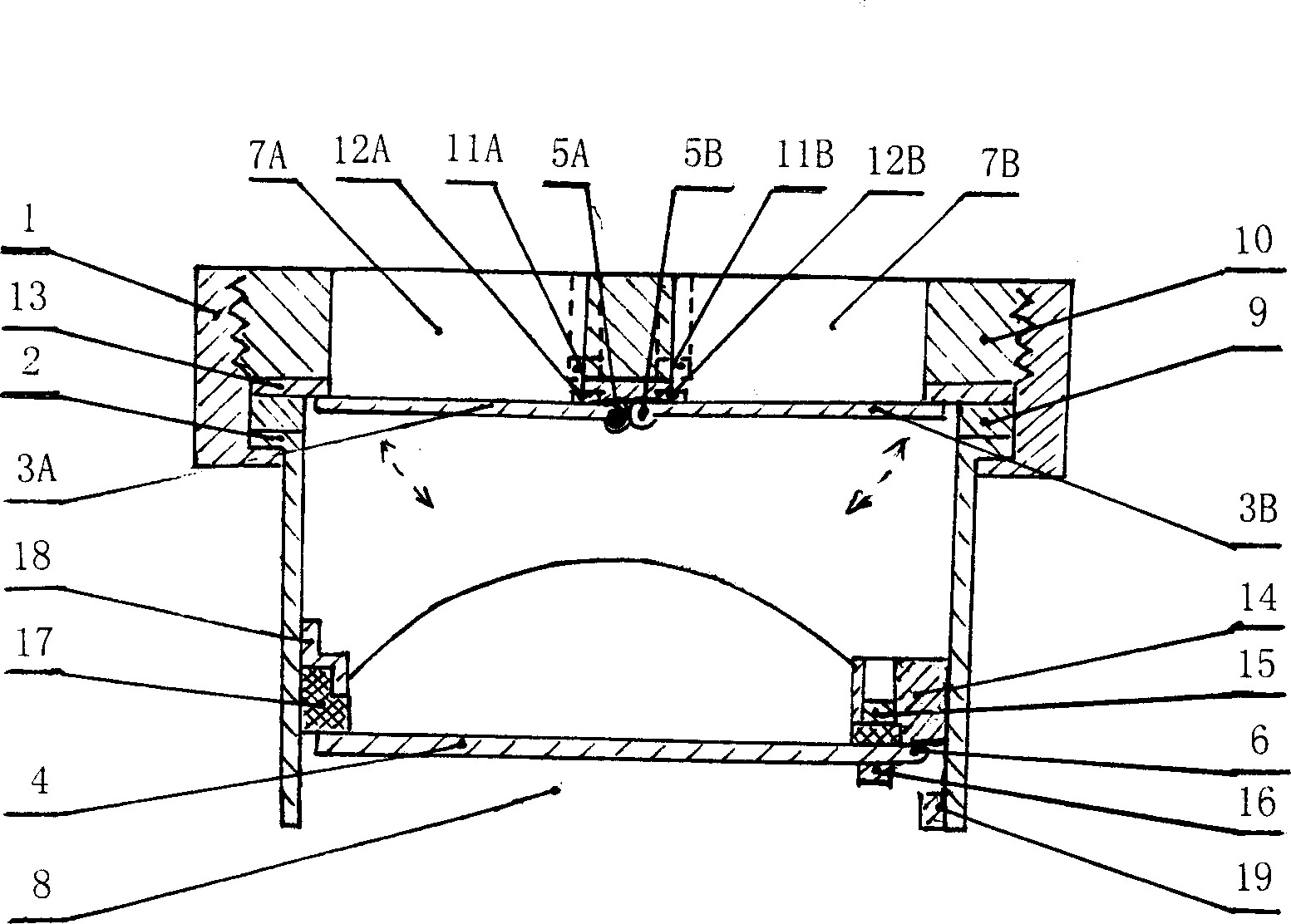

[0020] figure 1 It is one of the basic valve schemes - a schematic diagram of a double-piece valve. The double-piece valve is composed of an upper casing (1), a lower casing (2), a double-piece valve (3), a double-piece valve shaft (5), and a fluid inlet ( 7A, 7B), bearing bracket ring (9), double-piece valve bracket (10), permanent magnet (11), permanent magnet (12), elastic magnetic sealing ring (13) composed of a cylinder with snap-in annular surface shaped valve body.

[0021] The basic operating principle of the double-plate valve is: the double-plate valve (3) works by pressure difference. When the pressure of the fluid inlet (7) exceeds the opening threshold of the double-piece valve (3), the permanent magnet (12) on the double-piece valve (3) and the permanent magnet (11) in the double-piece valve bracket (10) begin to interact with each other At the same time their mutual magnetic attraction begins to decrease, the double-plate valve (3) opens, and the sewage passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com