Support for a railborne vehicle and console

A technology for vehicles and supporting beams, which is applied in the field of supporting beams for roadways, can solve problems such as large installation methods, high loads of vehicles, and high cost, and achieves avoiding dangerous icing, avoiding damage, and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

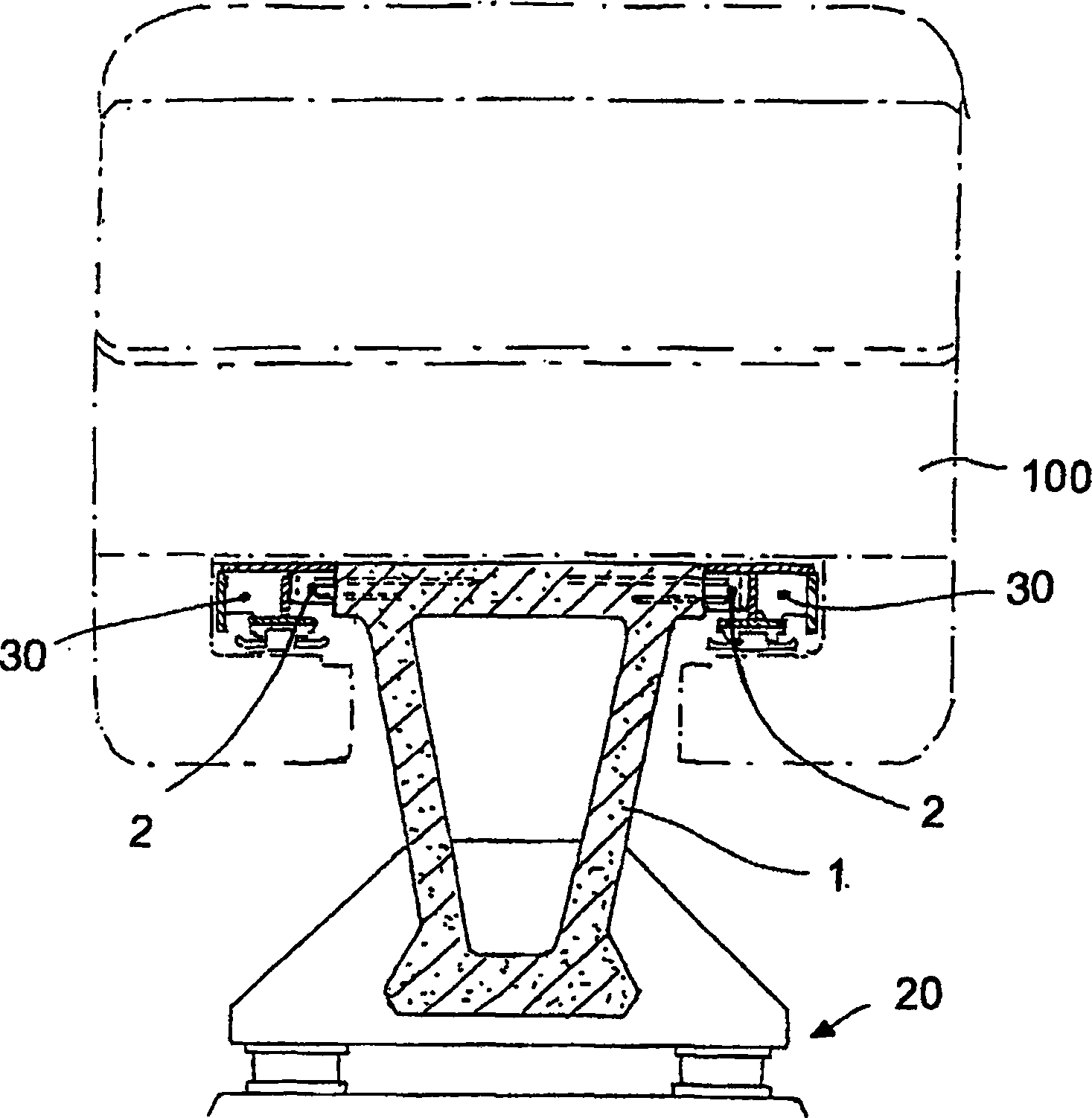

[0043] figure 1 A cross section of an existing roadway for magnetic levitation track 100 is shown in. The magnetic levitation rail 100 surrounds the clamping functional plane supporting beam 30, and the functional plane supporting beam 30 is fixed to the side of the supporting beam 1. The functional plane support beam 30 is fixed by a plurality of cantilever arms 2, and the cantilever arms 2 are arranged on the support beam 1 at intervals. The supporting beam 1 is a prefabricated concrete member erected on a support 20. In order to ensure the orderly operation of the magnetic levitation track 100, it is important to arrange the functional plane support beams 30 in a certain position with each other and assemble with the support beam 1. Only when the functional plane support beam 30 is accurately arranged, can the magnetic levitation track 100 work reliably at extremely high speeds. Therefore, the functional plane support beam is provided with a mounting surface, a lateral guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com