Burner with ignition needle protection structure

A technology for protecting structures and burners, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of ignition needle pollution, ignition failure, explosion of the ceramic outer wall of the ignition needle, etc., to avoid explosion, improve speed and Success rate and effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

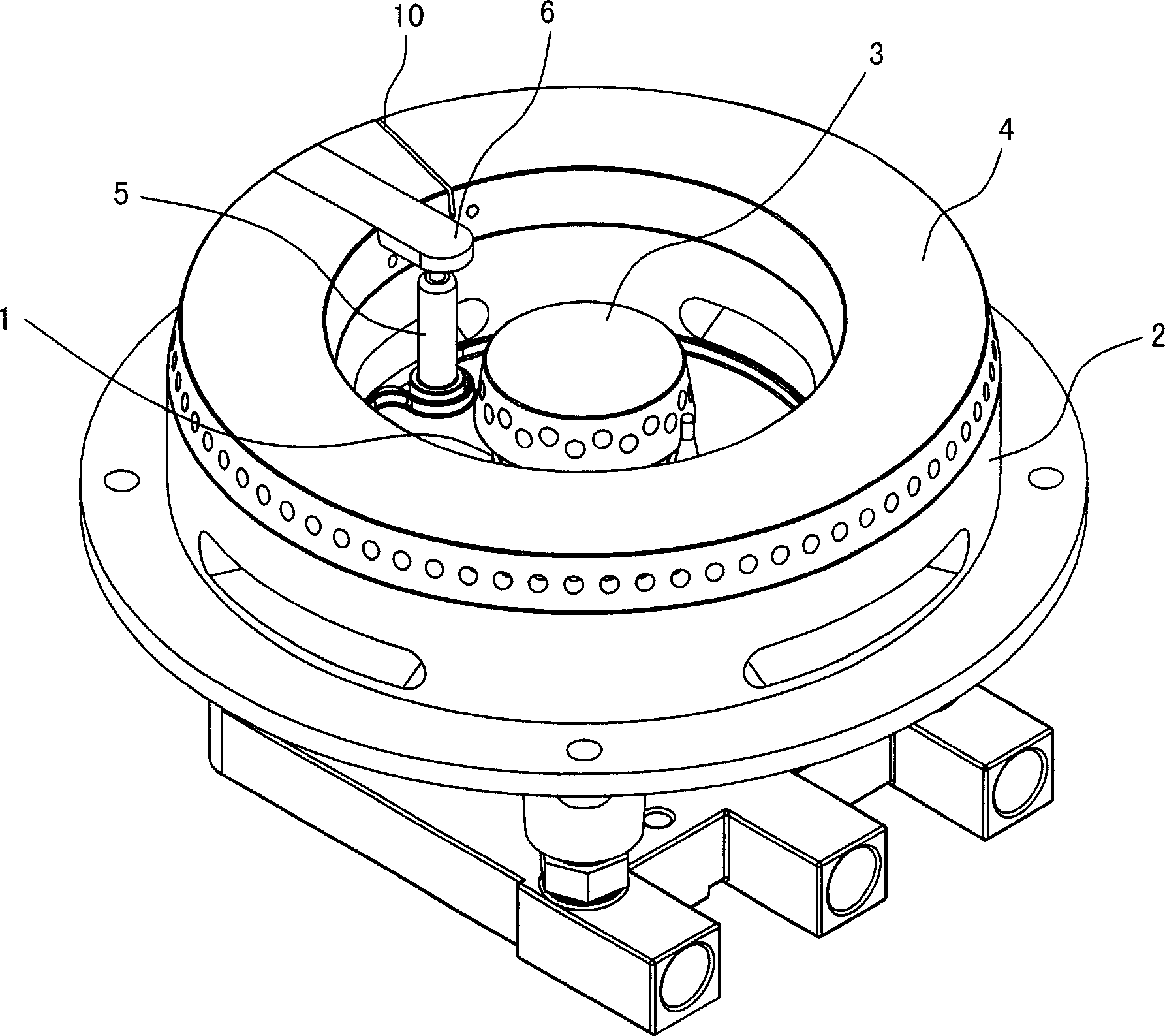

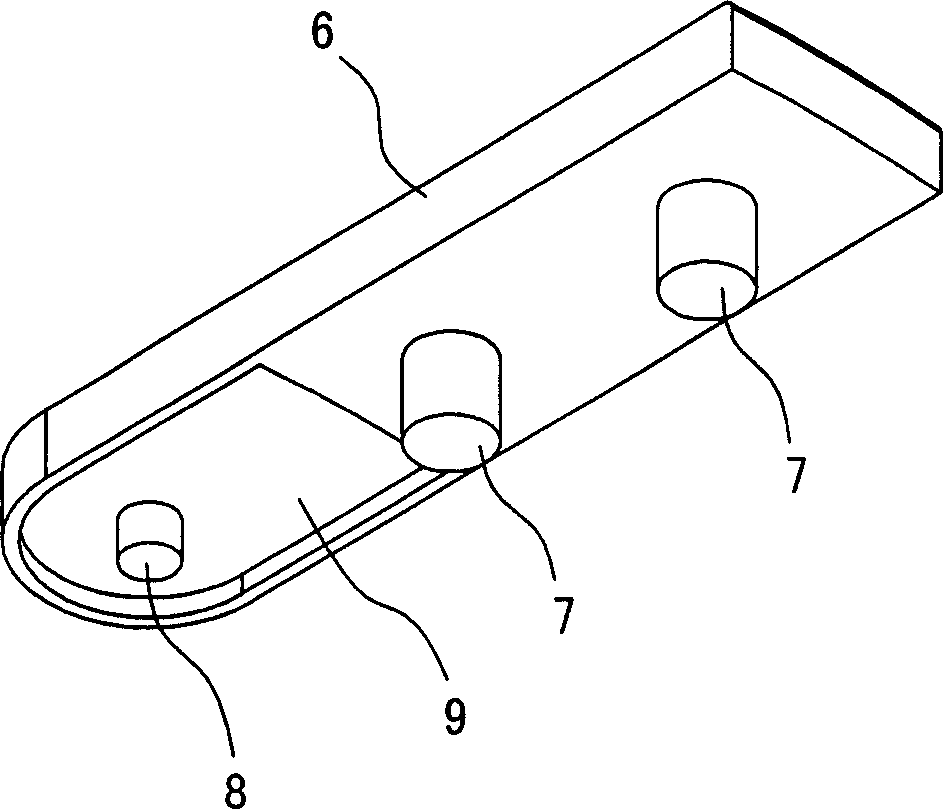

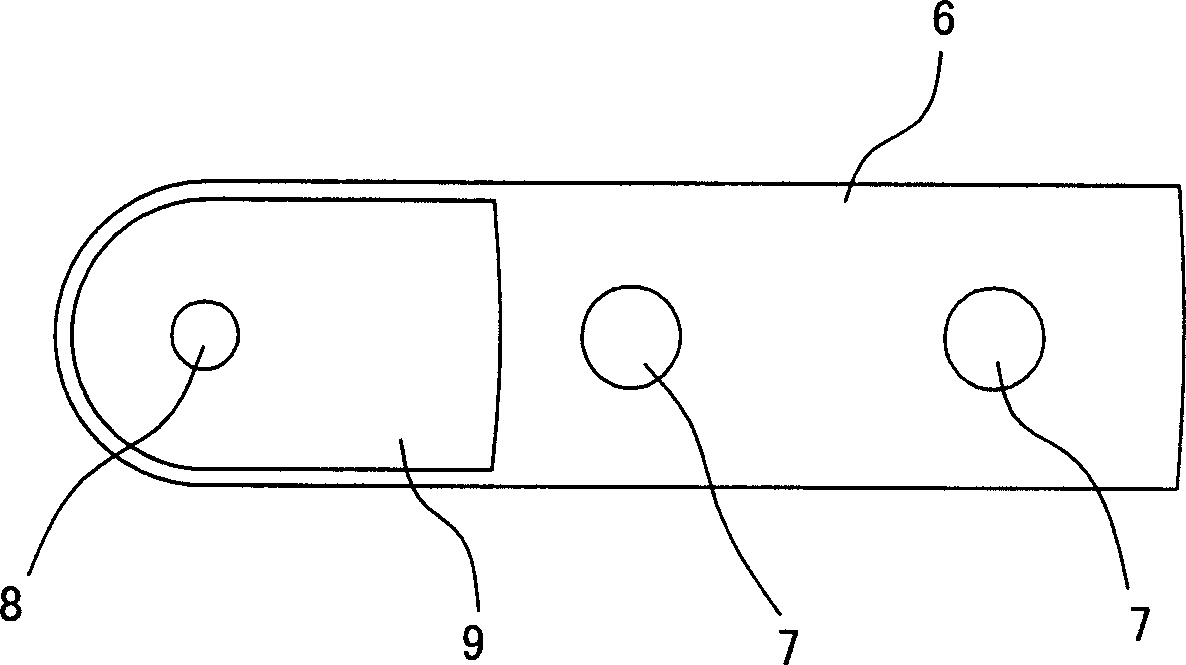

[0031] Such as Figure 1 ~ Figure 4 Shown is a preferred embodiment of the present invention. Such as Figure 1 ~ Figure 4 As shown, the burner with ignition needle protection structure in this embodiment has an inner air mixing chamber 1, an outer ring air mixing chamber 2, an inner ring fire cover 3, an outer ring fire cover 4 and an ignition needle 5, and also has a setting On the block-shaped protective cover 6 above the ignition pin 5, the lower surface of the rear end of the protective cover 6 extends downward with two positioning pins 7, and the lower surface of its front end extends downwards corresponding to the position of the ignition pin 5. The protruding needle 8 is formed with a concave area 9 around the periphery of the protruding needle 8. The outer ring fire cover 4 is provided with a positioning groove adapted to the rear end of the protective cover 6 , and the bottom of the positioning groove is provided with a positioning hole adapted to the positioning p...

Embodiment 2

[0033] Such as Figure 5 ~ Figure 6 shown, and see figure 1 , the burner of this embodiment, the protective cover 6 arranged above the ignition needle 5 is a section of arc-shaped protrusion horizontally extending from the outer ring fire cover 4 to the inside, and the upper surface and the lower surface of the protective cover 6 are both Neat plane.

Embodiment 3

[0035] Such as Figure 7 ~ Figure 8 shown, and see figure 1 For the burner in this embodiment, the protective cover 6 arranged above the ignition pin 5 is a circle of ring-shaped bumps extending horizontally from the outer ring ignition cover 4 to the inside, and the upper surface and the lower surface of the protective cover 6 are both for a neat plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com