Method of processing the output signal of a measuring transducer and force measuring device for carrying out the method.

A technology for measuring sensors and force-measuring devices, applied in measuring devices, instruments, weighing, etc., can solve problems such as short response time to oscillation interference, short transient oscillation establishment time, complex and expensive scheme, etc., to achieve optimal damping, shortest Build time, the effect of shortening the build time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

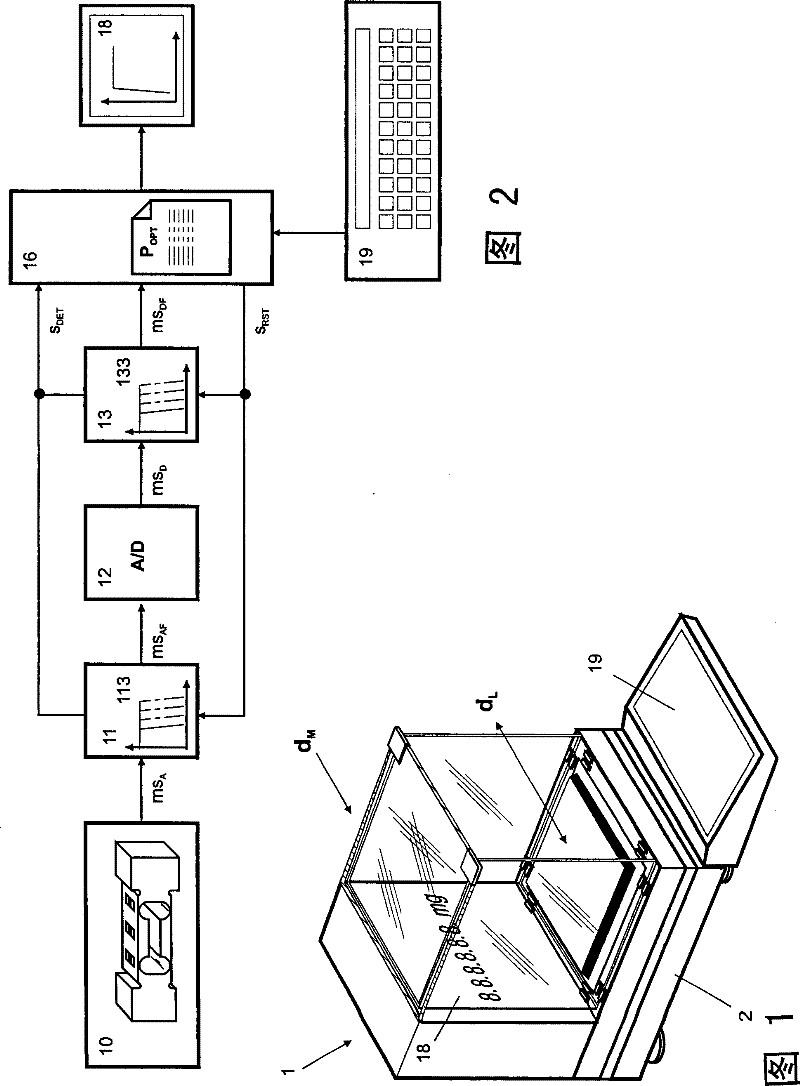

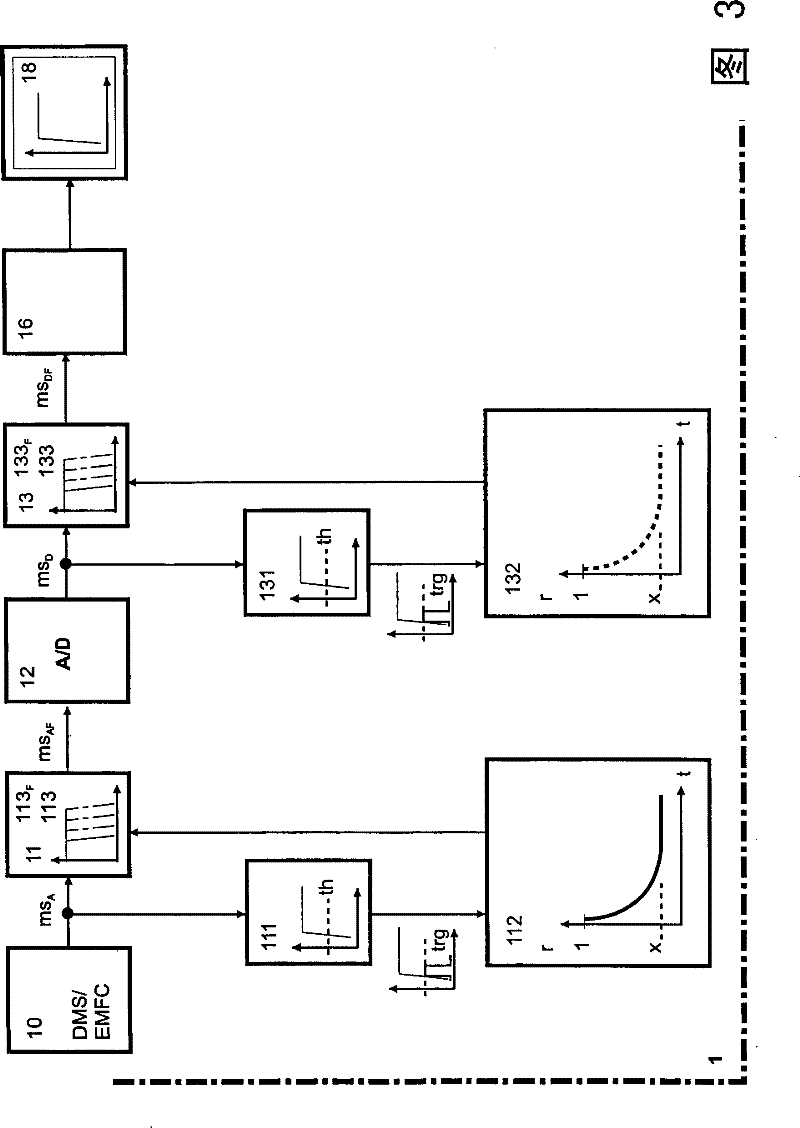

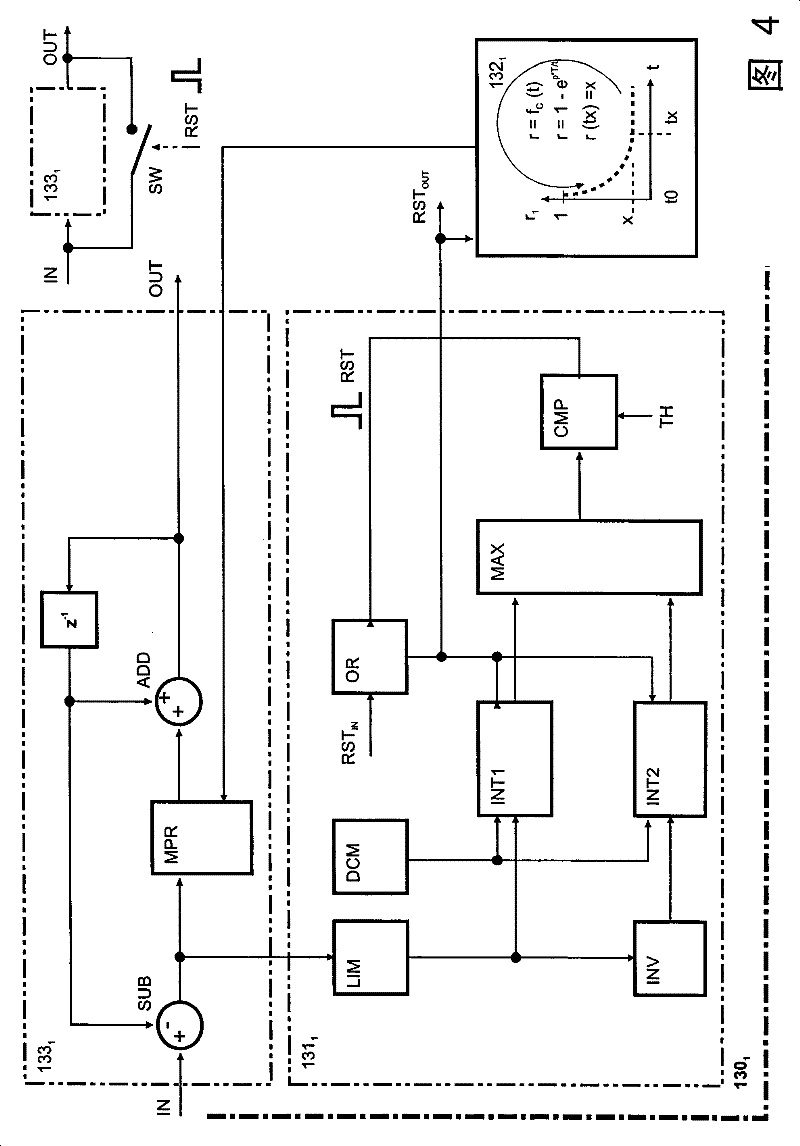

[0061] figure 1 Shown as an example is a scale 1 according to the invention with a symbolically indicated external influence d M and d L , said influencing factor has a great influence on the time distribution of the measurement signal ms. The time distribution of the signal is on the one hand as the weighing load changes d L function changes. The signal distribution also depends on the mechanical influence d M , such as vibrations and shocks, which cause some parts of the scale, in particular the measuring sensor or parts thereof, to oscillate. even during changes in the load acting on the scale d L Having already occurred, mechanical disturbances also each time lead to transient oscillations superimposed on the useful signal. The signal processing unit in the scale 1 therefore has the task of separating the signal portion representing the weighing load from the useless signal portion caused by vibrations, shocks and load changes in the best and fastest manner. This is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com