Cooling process and device for a steel sheet

A technology of cooling device and steel strip, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problem of low cooling rate and achieve uniform spraying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

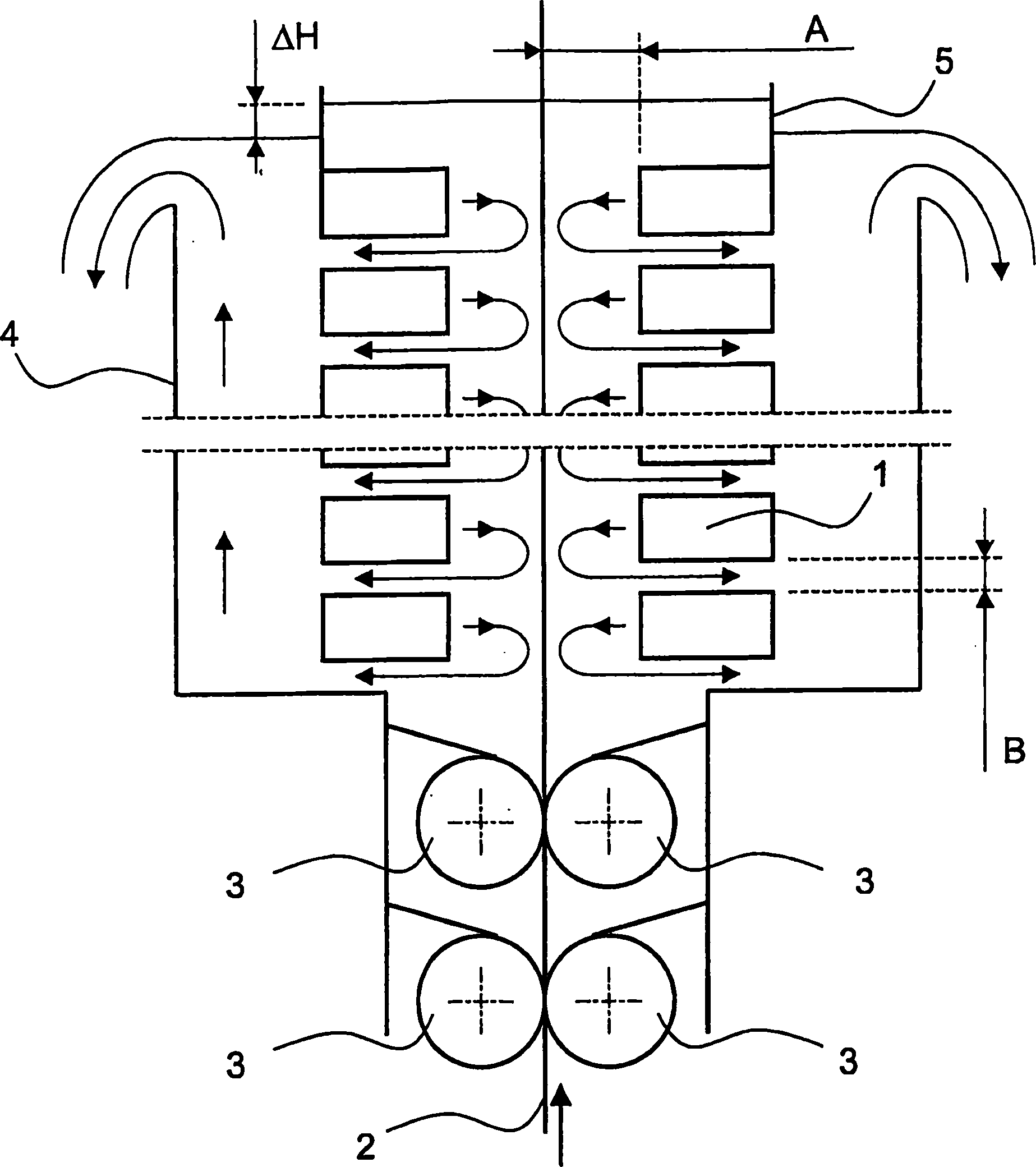

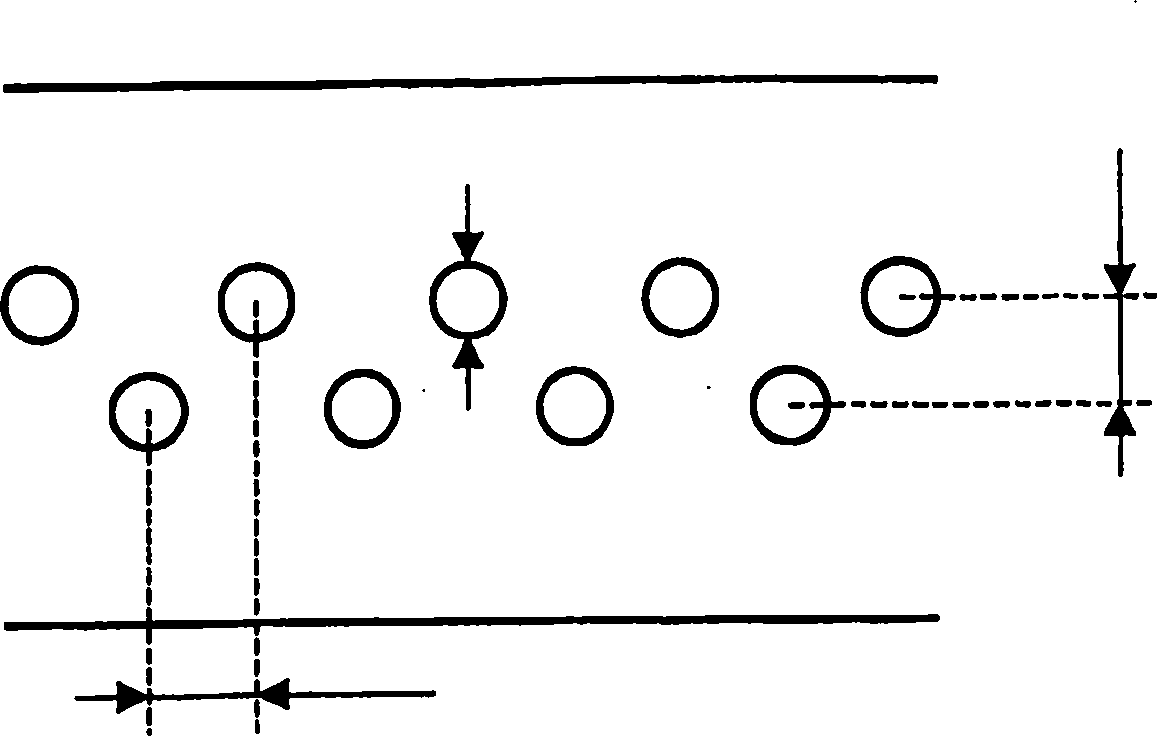

[0068] [65] If figure 1 As shown, the cooling device includes a group of pipes 1, which are called "workbench" or "cooling workbench", and these pipes are symmetrically arranged on both sides of the steel strip to be cooled. These tables are immersed in cooling fluid and are supplied with cooling fluid in the transverse direction. Their cross-section is preferably rectangular. In the further description of the invention, the words "pipe" and "table" are used without distinction.

[0069] [66] The immersion of the workbench into the fluid is achieved by means of a sealing system located in the lower part of the device, which allows the passage of the steel belt 2 and creates a maximum load loss in order to direct the cooling fluid to the bottom of the housing Leakage is limited to a minimum. In the present application, the sealing system consists of two pairs of roller bodies 3 which are pressed against the steel belt and positioned symmetrically with respect to the steel be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com