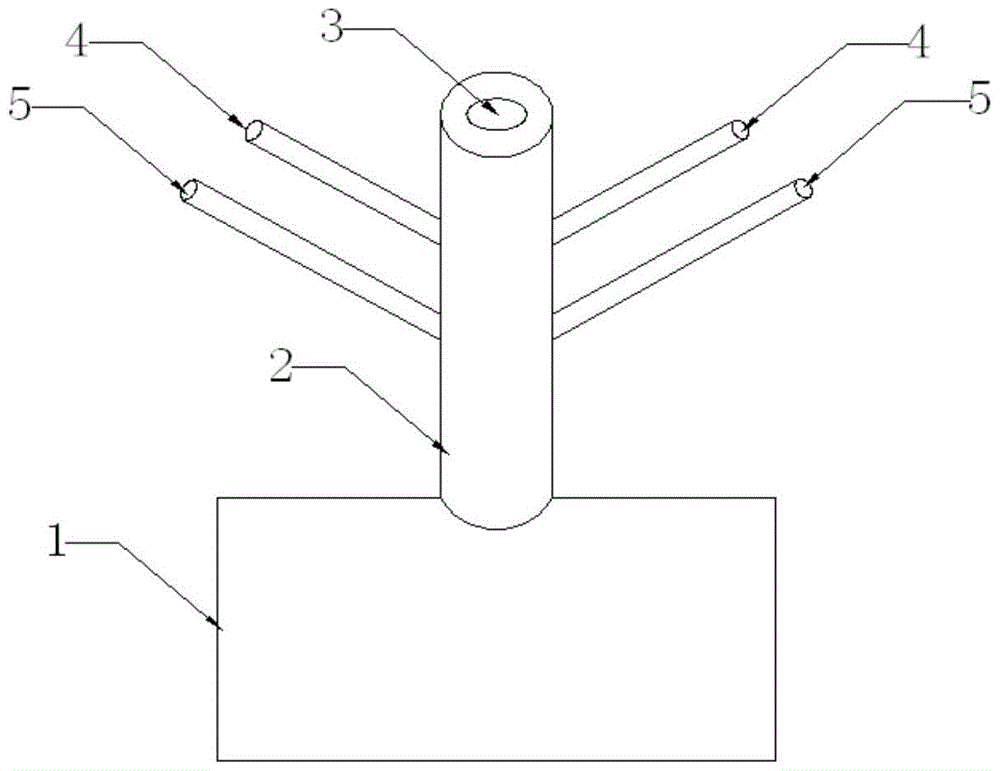

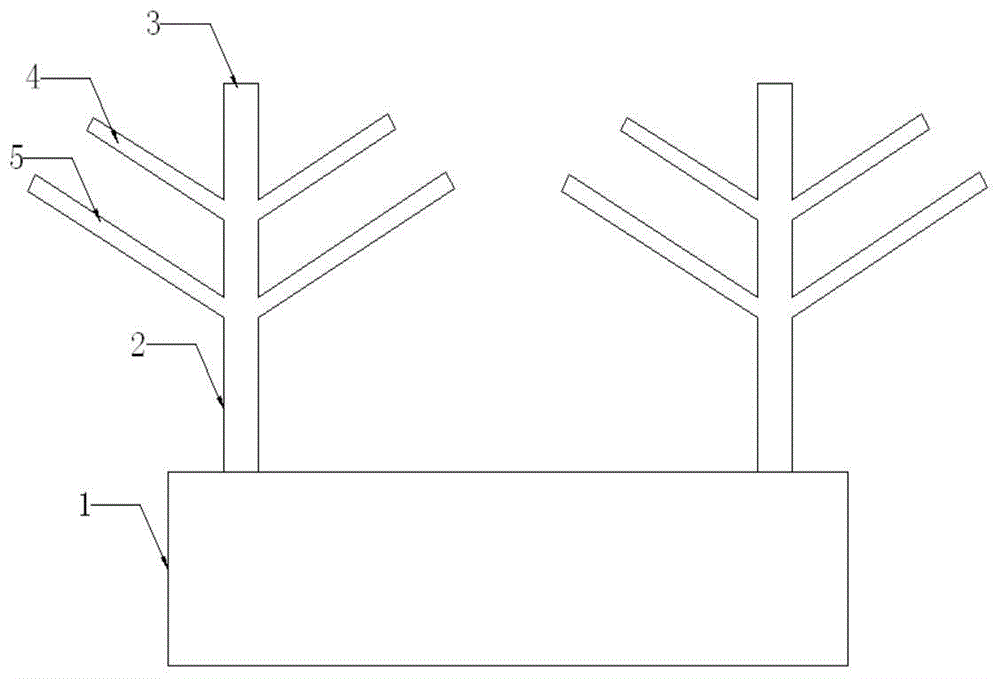

A nozzle device for ozone flue gas mixing system

A nozzle device and flue gas mixing technology, which is applied in the field of waste gas treatment, can solve the problems of poor flue gas disturbance effect, single spray angle, and large fluctuation of ozone spray speed, so as to improve the oxidation rate of nitrogen oxides, uniform spray speed, The effect that the mixing effect improves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] at 5000m 3 The process of ozone oxidation of NO in flue gas was simulated on a device of / h scale. The length of the flue is 3m, and a straight pipe is used to feed ozone into the flue to simulate the oxidation rate of NO without the device of the present invention. Flue gas volume 5000m 3 / h, the flue gas composition is as follows: O 2 is 9%, NO is 300ppm, and the rest is nitrogen, the flue gas temperature is 100 degrees Celsius, and the pressure is 1 atmosphere. Ozone according to the molar ratio O 3 : The ratio of NO=1 is injected, and the oxidation rate of NO at the outlet is 30%.

Embodiment 2

[0044] Under the optimal implementation mode of the present invention, at 5000m 3 The process of ozone oxidation of NO in flue gas was simulated on a device of / h scale. The flue length is 3m, and the flue gas volume is 5000m 3 / h, the flue gas composition is as follows: O 2 is 9%, NO is 300ppm, and the rest is nitrogen, the flue gas temperature is 100 degrees Celsius, and the pressure is 1 atmosphere. Ozone according to the molar ratio O 3 : The ratio of NO=1 is injected, and the oxidation rate of NO at the outlet is 75%.

Embodiment 3

[0046] Under the optimal implementation mode of the present invention, at 5000m 3 The process of ozone oxidation of NO in flue gas was simulated on a device of / h scale. The flue length is 3m, and the flue gas volume is 5000m 3 / h, the flue gas composition is as follows: O 2 is 9%, NO is 300ppm, and the rest is nitrogen, the flue gas temperature is 100 degrees Celsius, and the pressure is 1 atmosphere. Ozone according to the molar ratio O 3 : The ratio of NO=1.2 is injected, and the oxidation rate of NO at the outlet is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com