Tripod nozzle device of thermal power station ammonia-injection and denitration system

A thermal power plant and nozzle device technology, applied in the field of parts and components, can solve problems such as single injection angle, large deviation of ammonia concentration distribution in velocity distribution, poor flue gas disturbance effect, etc., achieve uniform injection velocity, improve denitrification efficiency, reduce The effect of small ammonia slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will become more obvious.

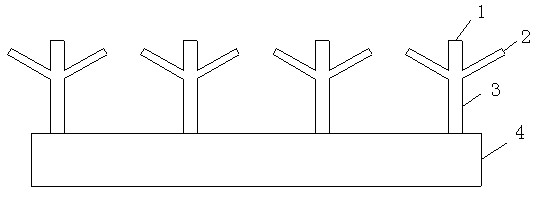

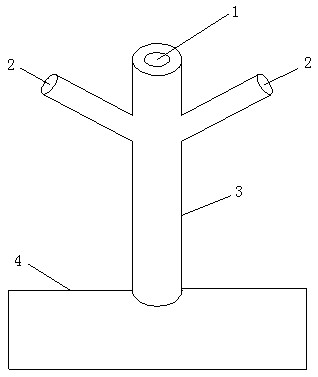

[0012] Such as figure 1 with 2 As shown, the ammonia injection and denitrification system of a thermal power plant comprises a mixing tube 4, and the trident nozzle device of the ammonia injection and denitrification system of a thermal power plant of the present invention includes a straight ammonia injection pipe 3 vertically inserted into the mixing tube 4, and an ammonia injection straight pipe 3. A central nozzle 1 is provided at the top, and two side nozzles 2 are symmetrically distributed on both sides of the straight ammonia injection pipe 3. The axis of the pipe 4 forms an included angle of 90°C, and the two side nozzles 2 and the straight ammonia injection pipe 3 are located on the same plane.

[0013] A large number of experiments have proved that when the diameter of the side no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com