Heated window pane

A glass plate and heating wire technology, which is applied in ohmic resistance heating, transparent/reflective heating devices, glass/slag layered products, etc., can solve the problems of unreachable length of heating wire, increased cost, and the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

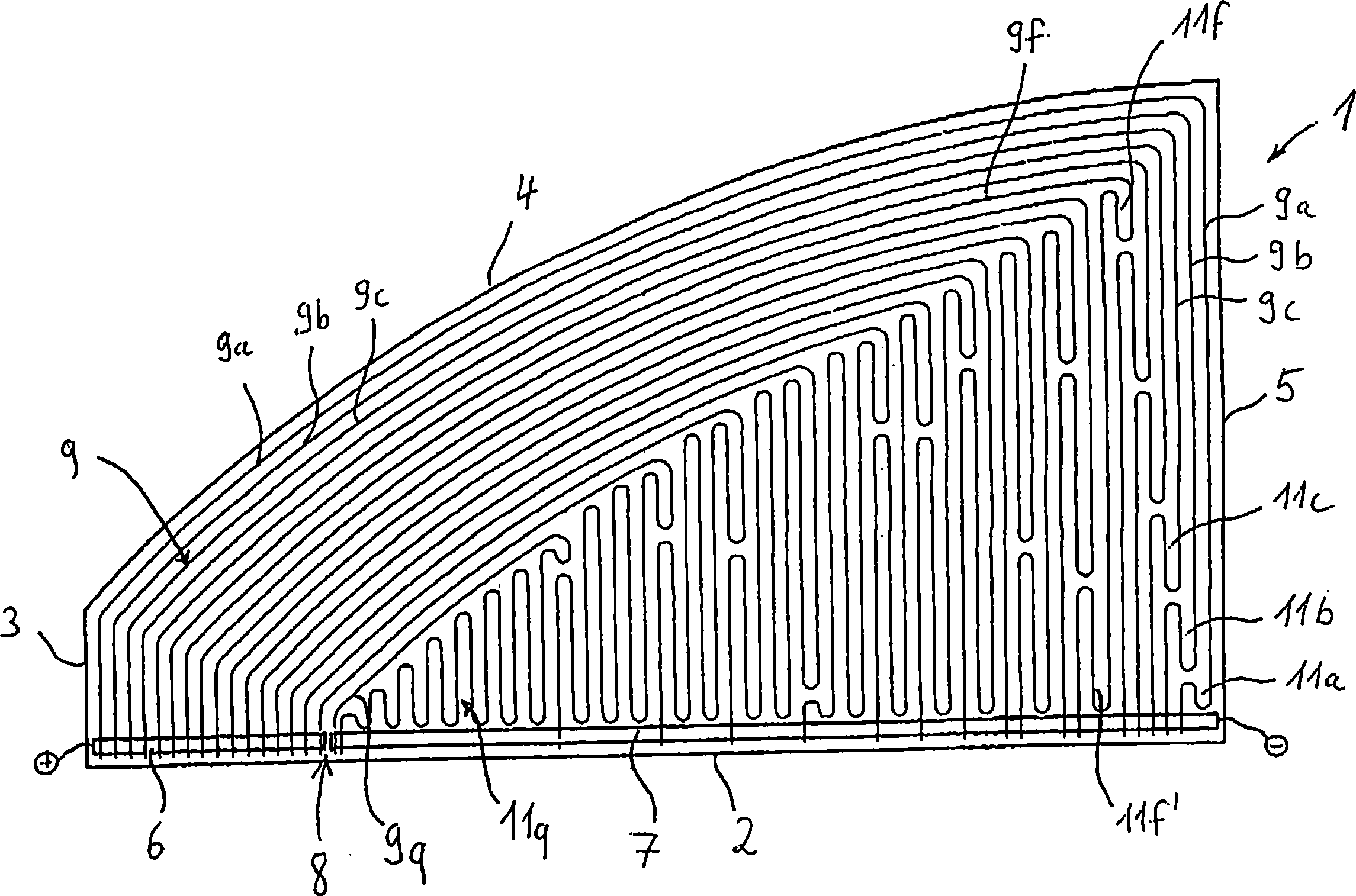

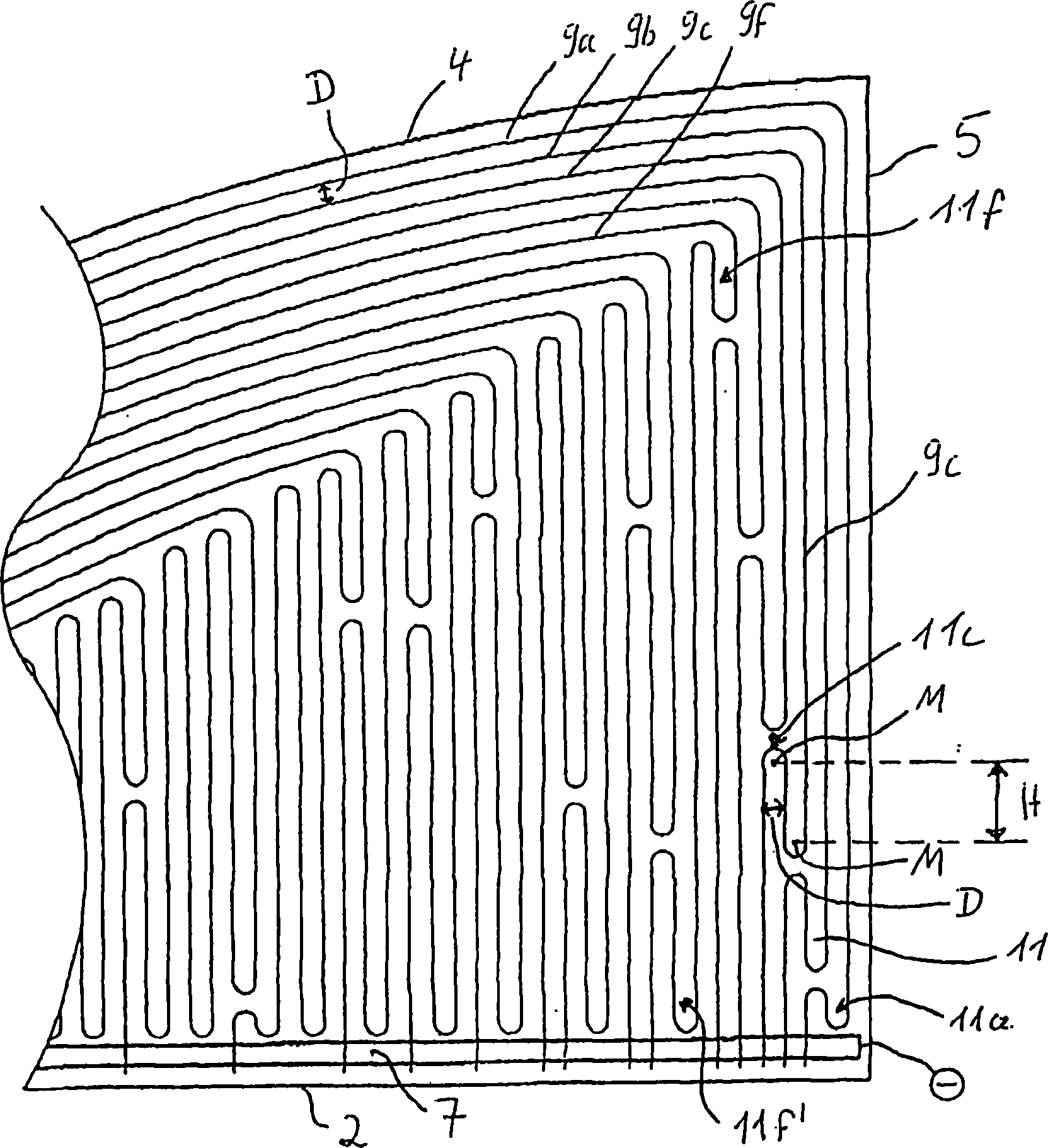

[0022] This is a laminated glass pane with a plastic foil (not visible) between two pane elements. Attached to the plastic foil are contact busbars 6, 7 and a bundle of heating wires 9.

[0023] Arranged along the bottom edge 2 are a contact busbar 6 to be connected to the positive pole of the DC power supply and a contact busbar 7 to be connected to the negative pole of the DC power supply (not shown), which are separated from each other by a gap 8 .

[0024] An outermost heating wire 9a electrically contacts the end of the bus bar 6 facing the front edge 3, and the heating wire 9a moves along the front edge 3, the upper edge 4 and the rear edge 5 to the rear facing side of the contact bus bar 7 The outer end of the edge 5 is in electrical contact with the contact busbar 7 . Next to the outermost heating wire 9a, a certain interval D is the second outermost heating wire 9b. According to the type of heating wire used and the required heating power density, the spacing D can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap