Automatic waste paper baler

A waste paper baler, fully automatic technology, applied in packaging, presses, manufacturing tools, etc., can solve the problems of high transportation costs, reduced transportation costs, and large space occupied by waste paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

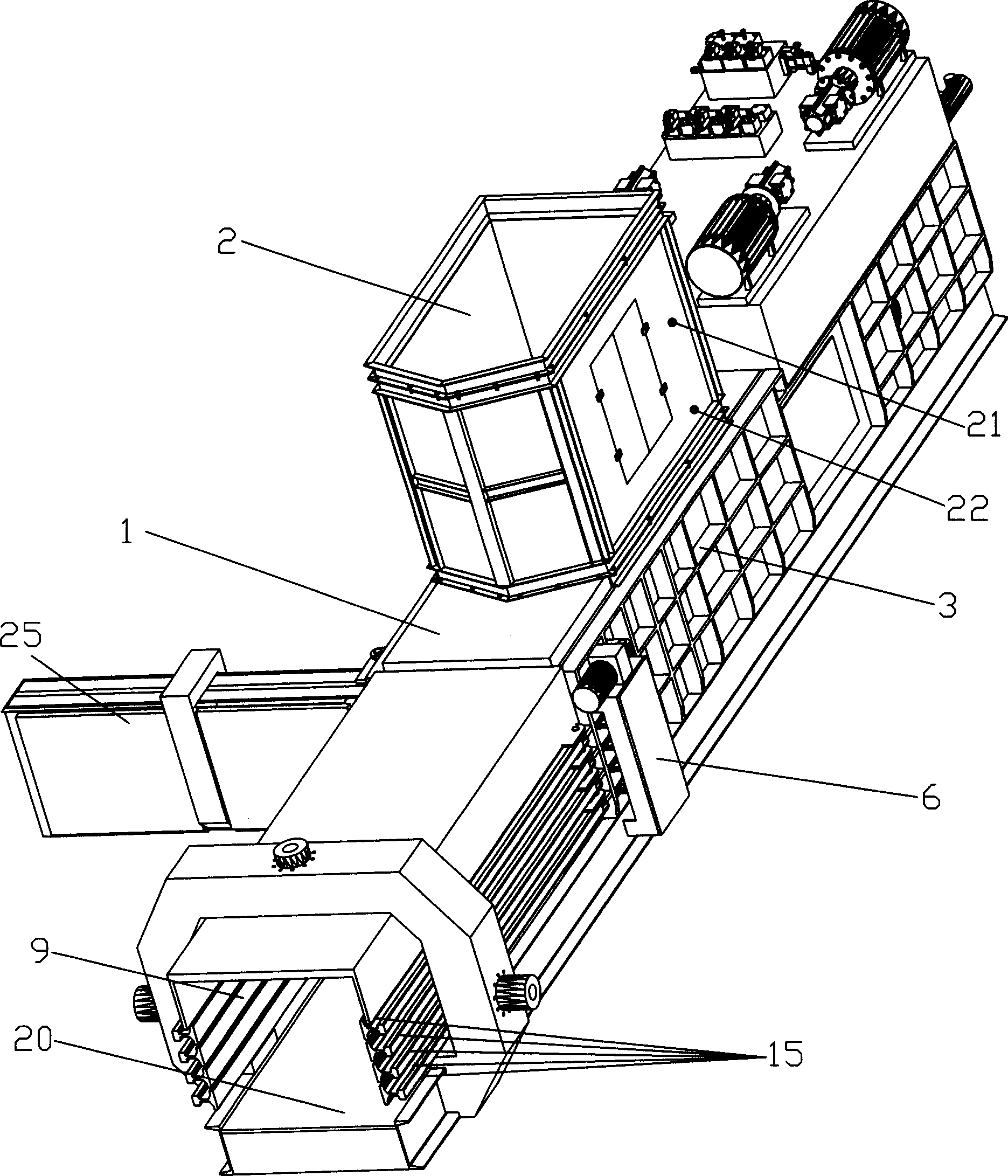

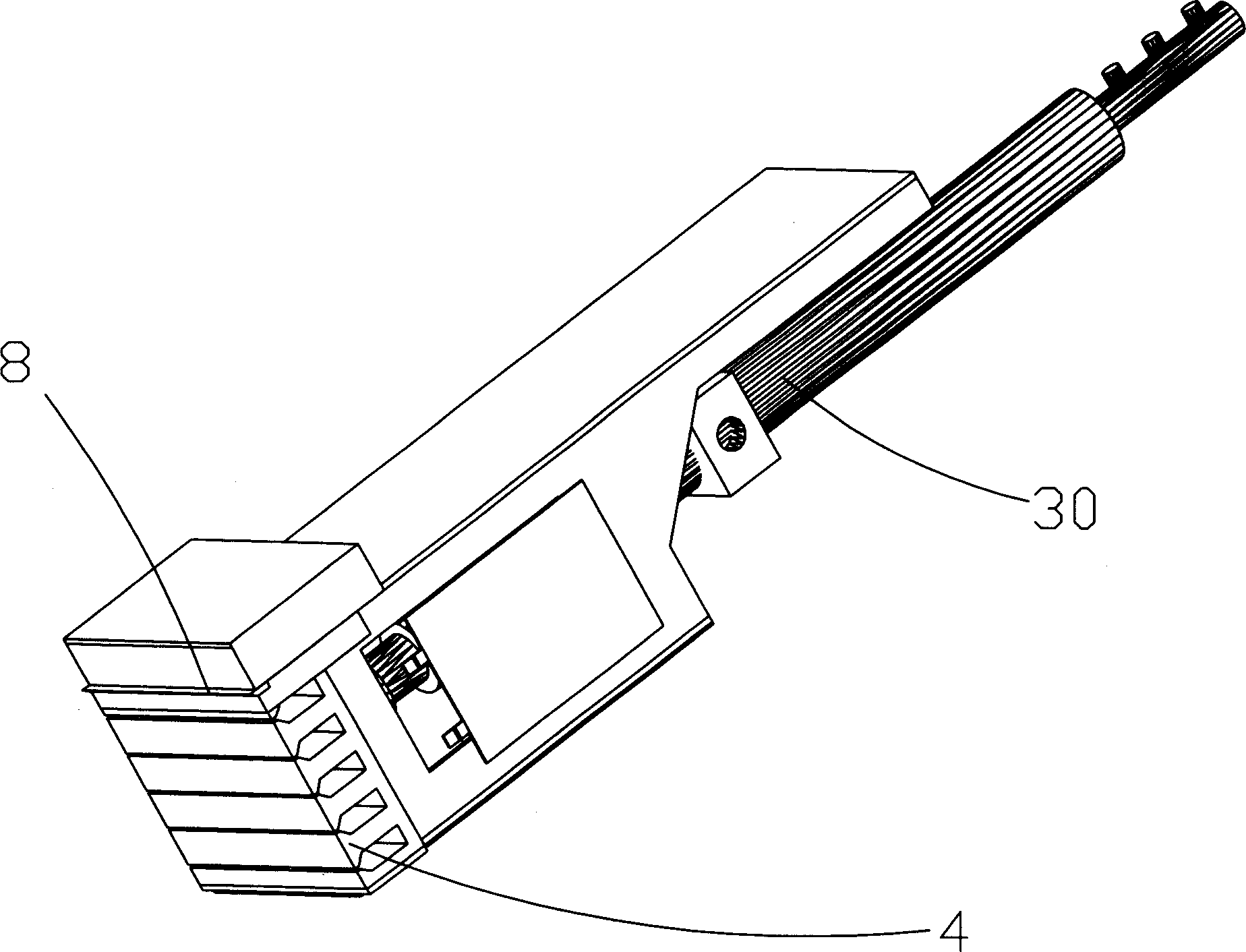

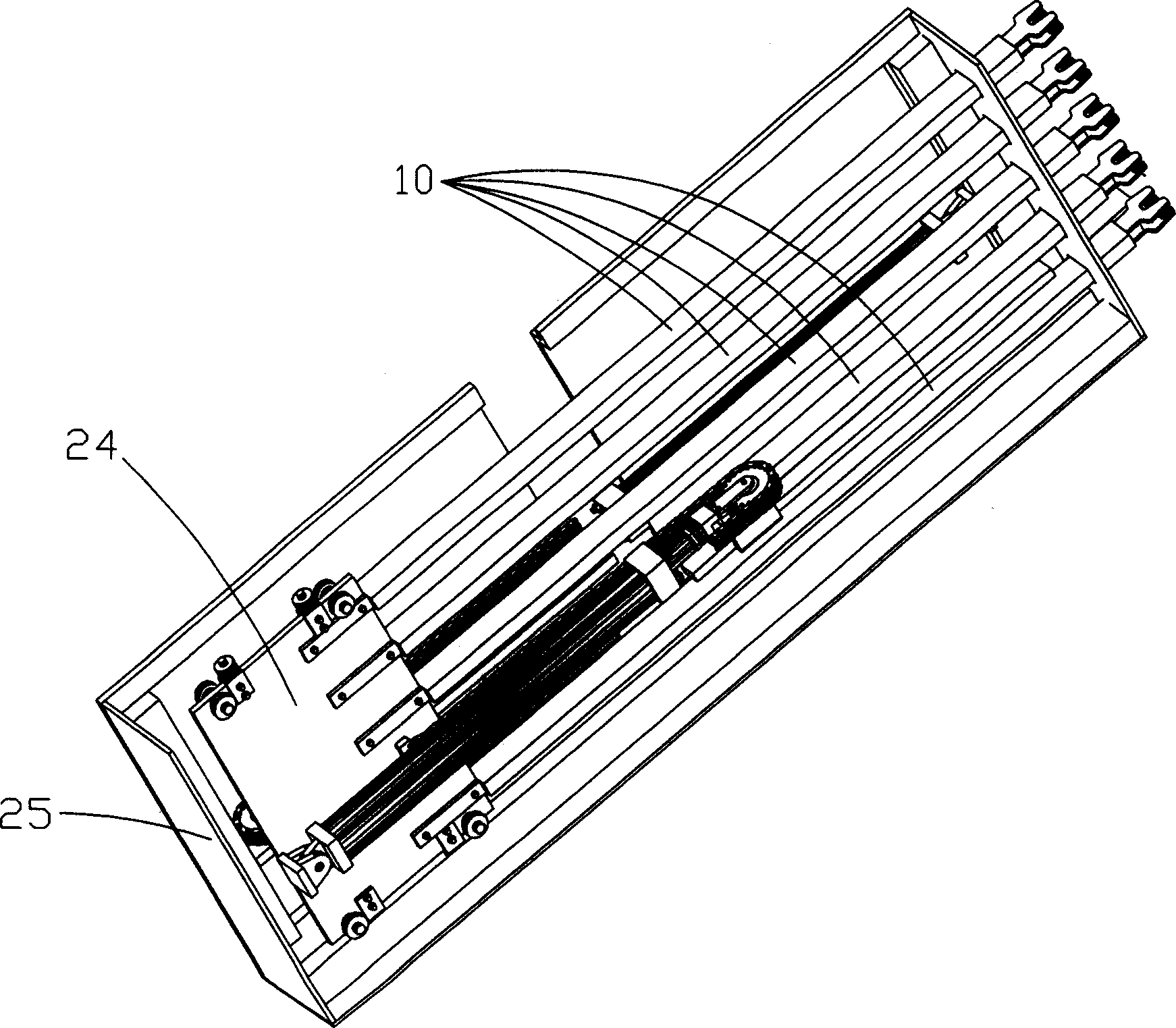

[0017] In order to further reveal the fully automatic waste paper baler of the present invention, the following will be described in conjunction with the examples, with the attached figure 1 , 2 , 3, 4, 5, and 6, it includes a frame 1, a paper feeding chamber 2, a paper pressing chamber 3, a push head 4, a threading rod 10, a threader 6, a hydraulic power unit, and the paper feeding chamber 2 communicates with the upper end of the paper press chamber 3, the left and right sides of the paper press chamber 3 are composed of steel plates installed on both sides of the frame 1, the bottom surface of which is formed by the machine base 20, and a rear end surface of the paper press chamber 3 is installed with a The push head 4 driven by the hydraulic cylinder 30 has a paper cutter 8 fixed on the push head 4. The paper cutter 8 is fixed on the top surface of the front end of the push head 4. When the push head 4 pushes the compressed waste paper, the paper cutter 8 Cut off the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com