Compound insulator

A technology of composite insulators and suspension insulators, applied in the direction of suspension/strained insulators, etc., can solve problems such as excessive research and development costs and time, inability to apply insulators, and inability to transform insulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

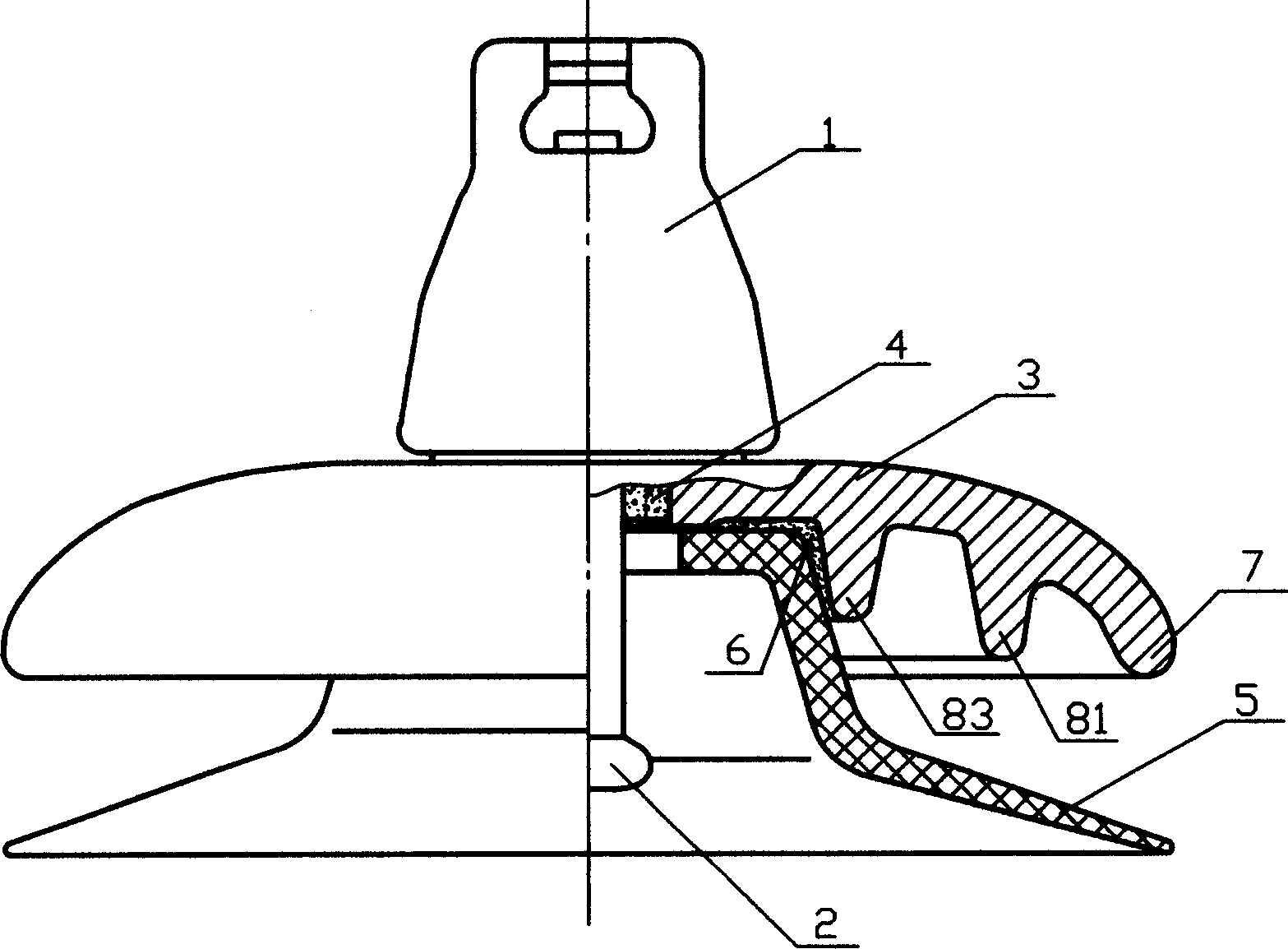

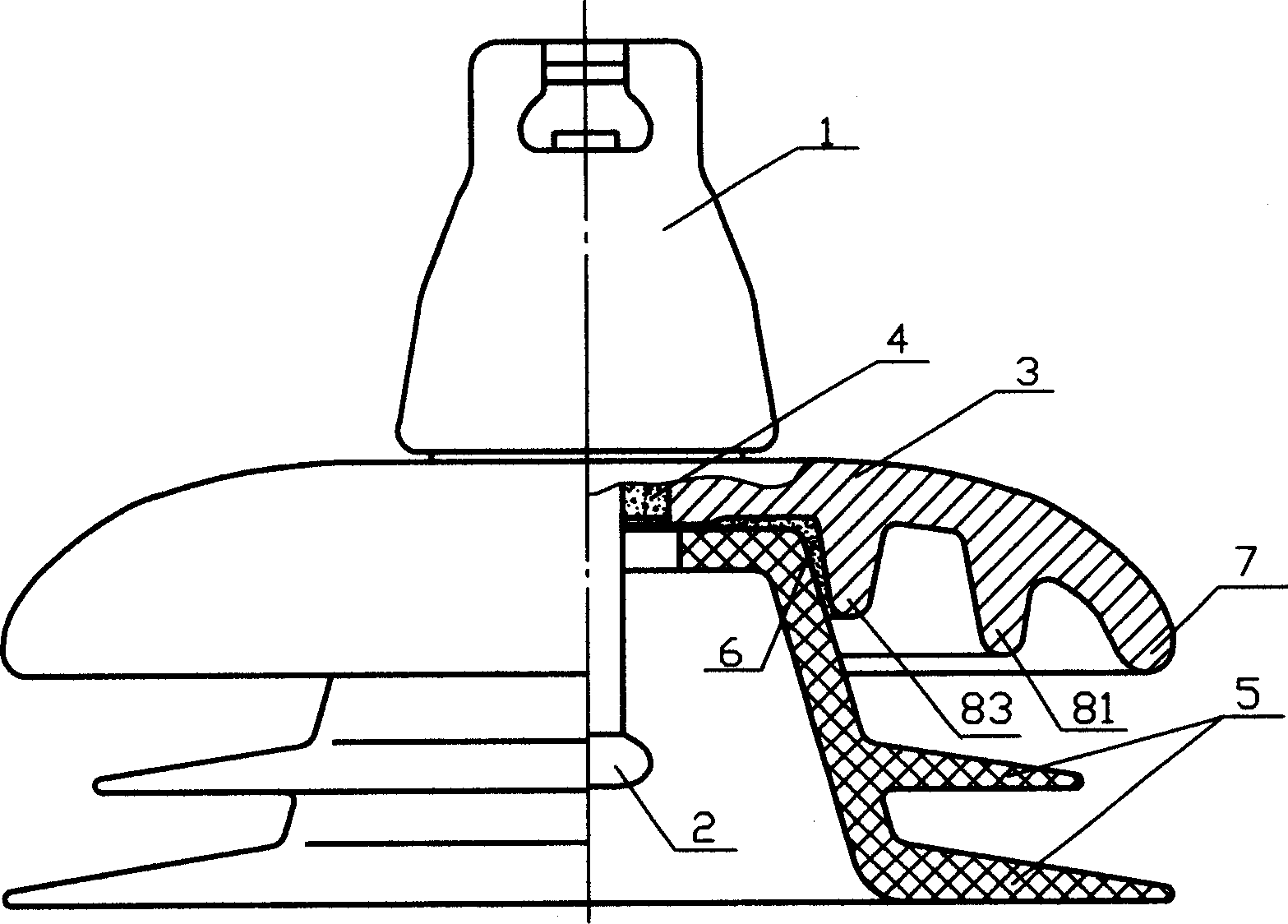

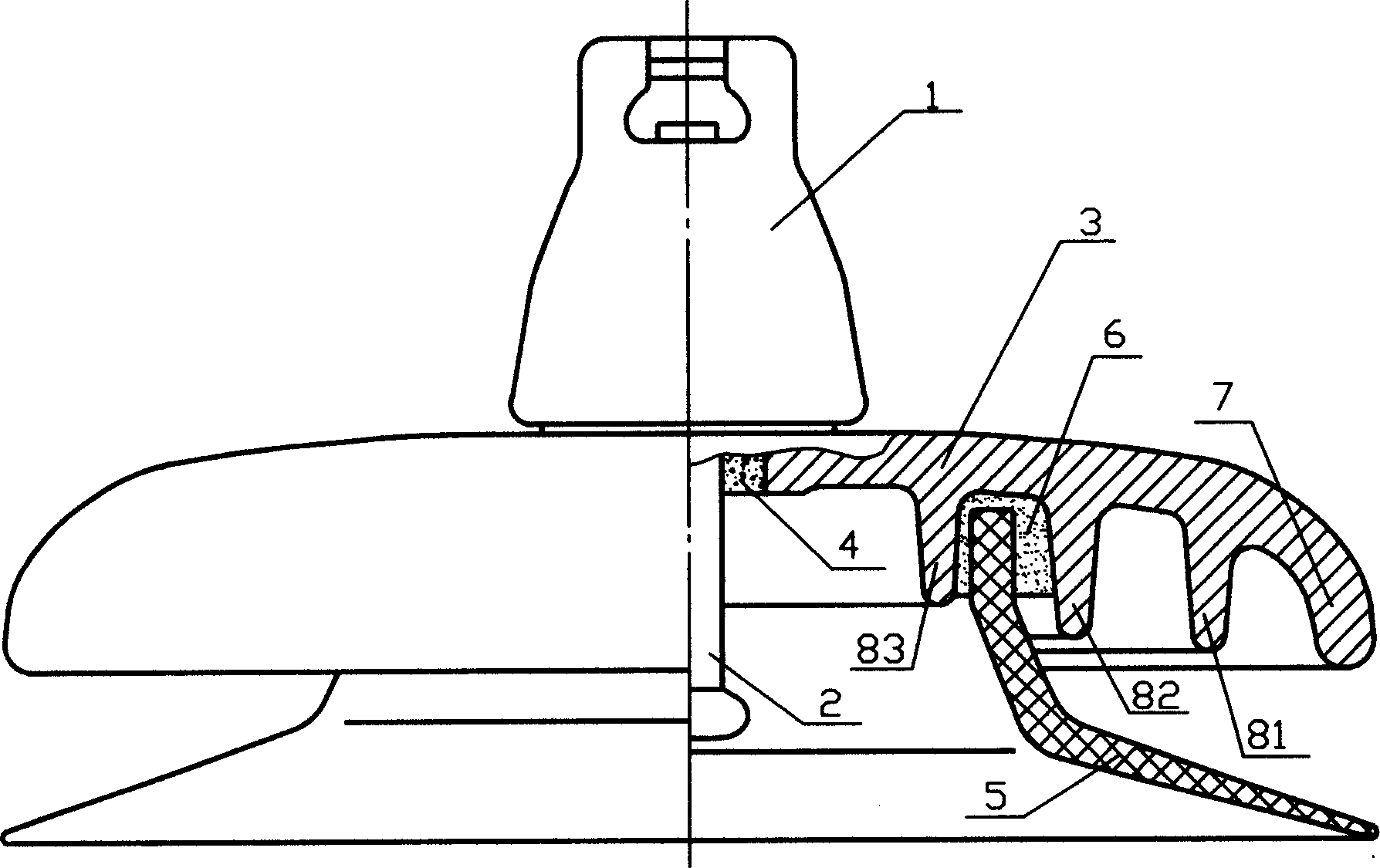

[0022] in the attached figure 1 Among them, the iron cap 1, the steel foot 2, the umbrella plate 3 and the adhesive material 4 together form a single-layer umbrella plate-shaped suspension insulator. The lower surface of the umbrella disk 3 of the suspension insulator has two downwardly protruding annular umbrella edges, that is, an outer umbrella edge 81 and an inner umbrella edge 83 , and a downwardly extending annular drip edge 7 . The structural height (note: this word is technical term) of this suspension insulator is 146 millimeters, and the diameter of umbrella disk 3 is 255 millimeters. The middle hole of synthetic shed 5 extends upwards in a tubular shape, and the top of the tubular extension and the lower surface of the umbrella disc 3 of said suspension insulator are bonded to each other by adhesive 6 (all sides of the ring-shaped umbrella edge are bonded together in the present invention) Both the surface and the lower surface are regarded as part of the lower sur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap