Stacker crane

A lift and stacking technology, applied in the field of stacking lifts, can solve the problems of increased vibration and increased mast dust, and achieve the effects of reducing load, suppressing vibration and dust, and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

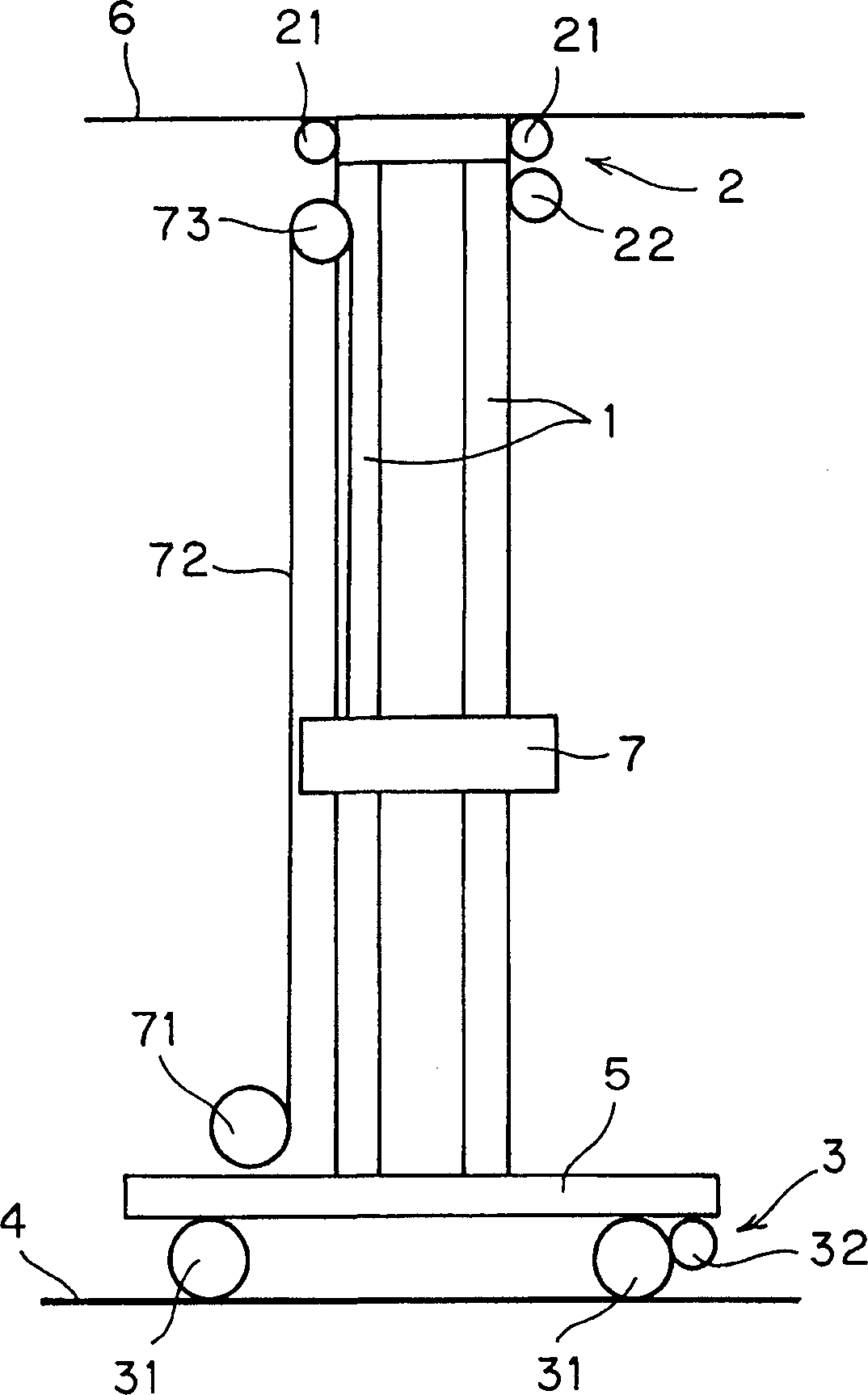

[0031] figure 1 An embodiment of the stacker elevator of the invention is shown.

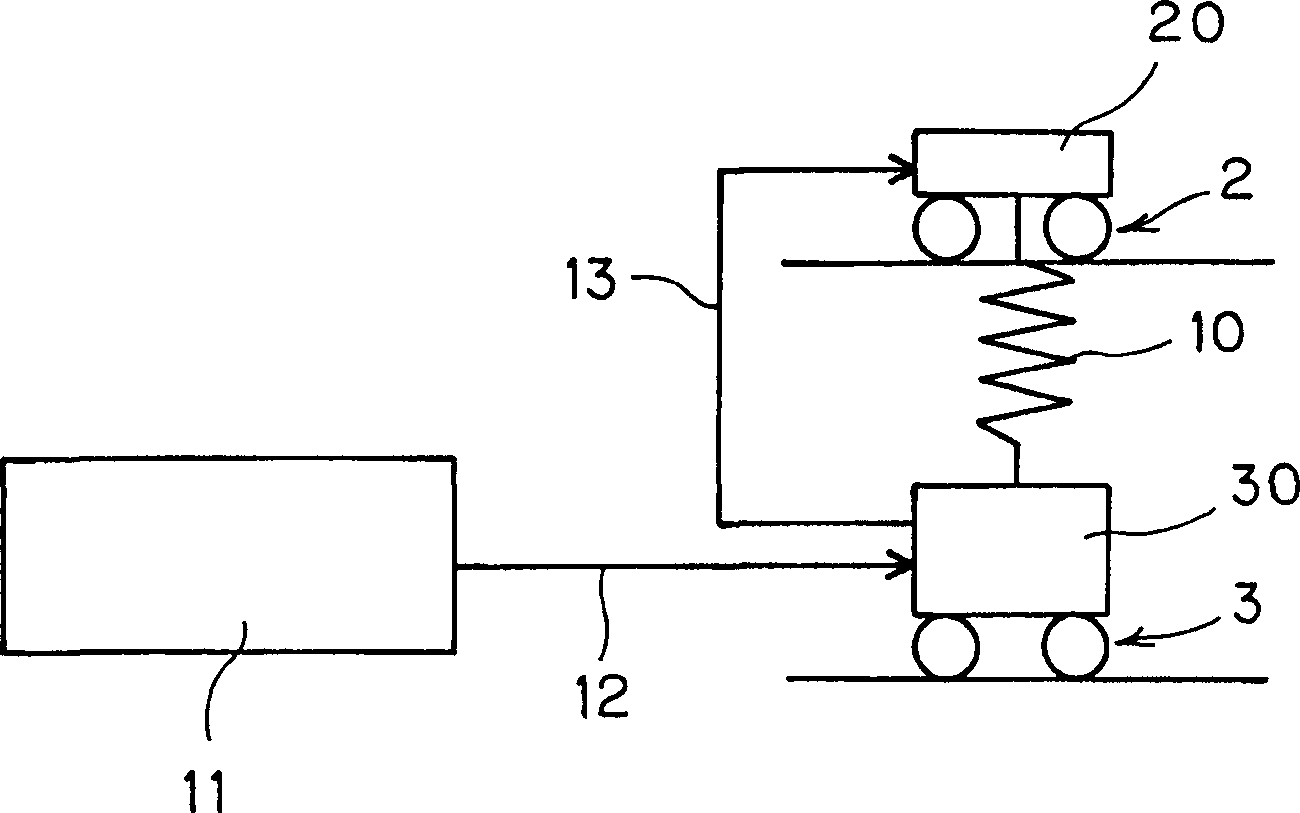

[0032] The stacker elevator of the present embodiment is respectively provided with an upper travel drive device 2 and a lower travel drive device 3 at the top and bottom of the mast 1 of the stacker lifter. While using the lower travel drive device 3 to implement the travel and position control of the stacker elevator, the upper travel drive device 2 is driven according to the speed signal of the lower travel drive device 3, and the vibration of the mast 1 is suppressed by the upper travel drive device 2 .

[0033] The lower driving device 3 includes lower driving wheels 31 running on the running rail 4 on the ground side and a lower driving motor 32 driving the lower driving wheels 31 on the traveling vehicle 5 .

[0034] In addition, the upper traveling driving device 2 is provided with an upper driving wheel 21 traveling along the support rail 6 on the ceiling side and an upper driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com