Mask for glass etching and its use for glass etching

A mask and glass technology is applied in the application field of etching the glass back cover of an organic electroluminescent display device, and achieves the effects of convenient use, low price and high groove precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

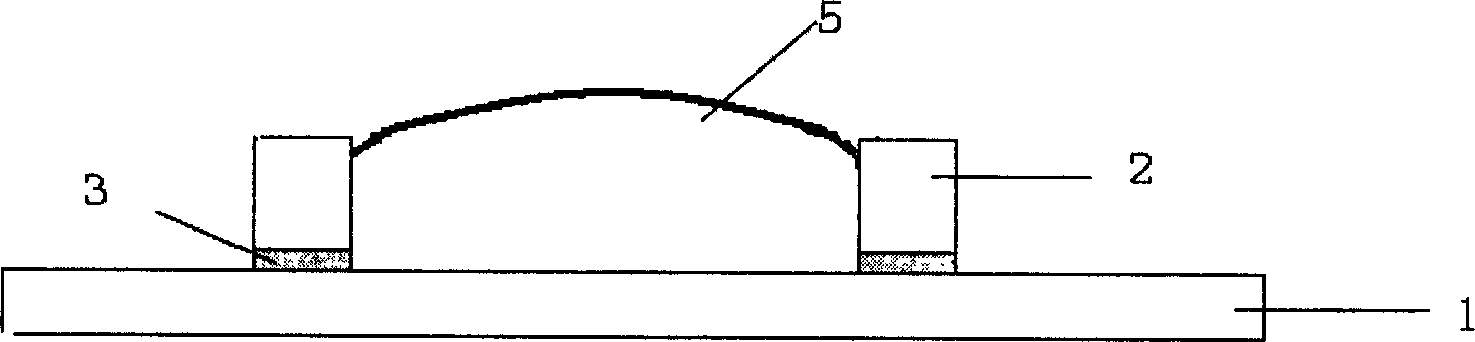

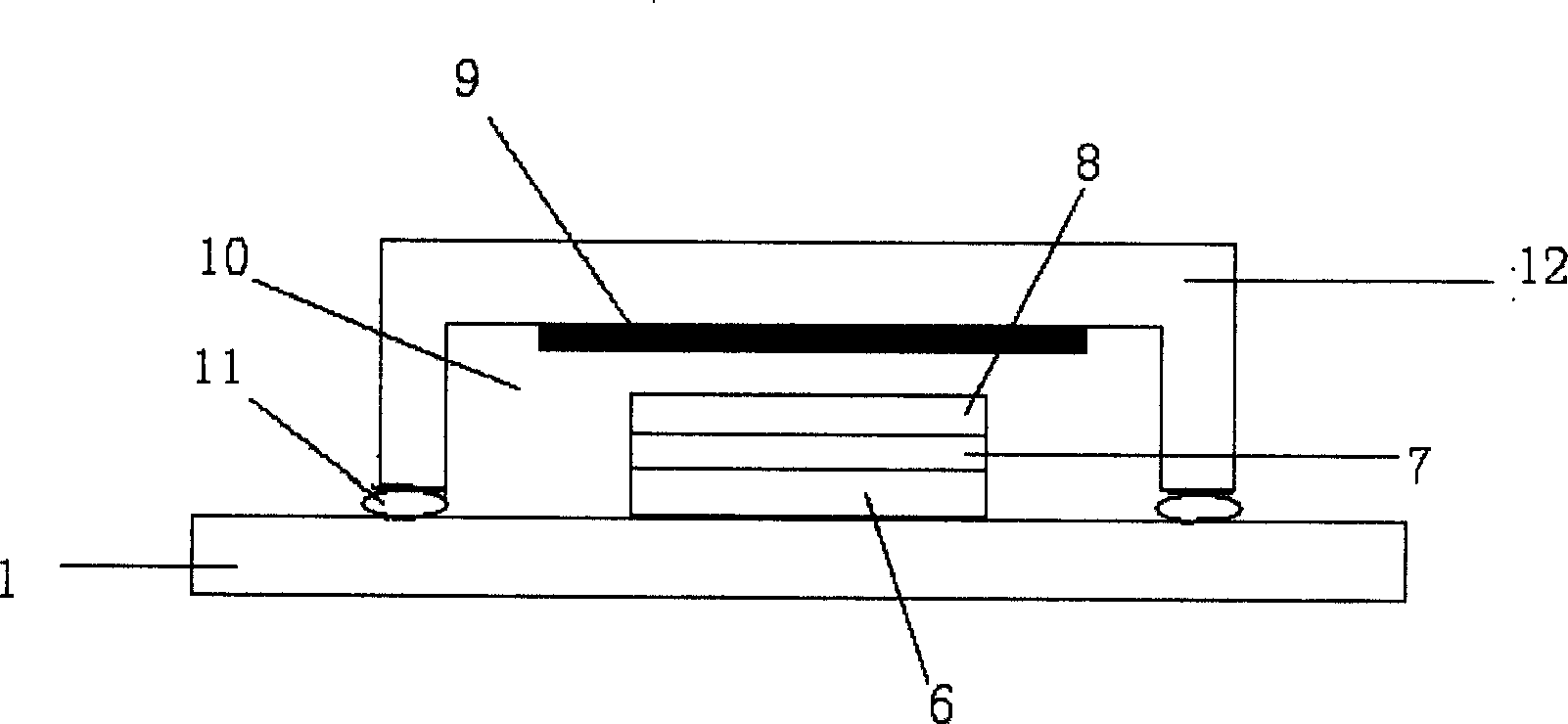

[0033] The manufacturing method of the glass back cover adopting the present invention will be further described in detail with reference to the attached schematic diagram.

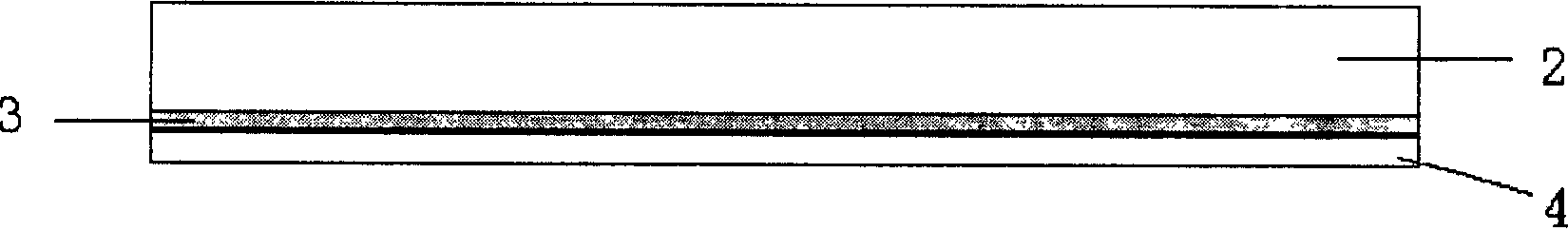

[0034] The present invention adopts the following technical scheme: by using a new material 2 mask to etch a groove 10 with a uniform depth and a flat bottom on the flat glass, the manufacture of the back cover of the device packaging glass is completed. The process method of etching the groove on the flat glass to make the glass back cover includes the following steps:

[0035] A. Cut out the glass plates of the required size for cleaning;

[0036] The size is selected according to needs. You can select a single glass plate that only needs to be etched locally, such as a single glass back cover, or multiple, such as forming a whole glass plate with multiple divisions on it. Glass back cover; after cleaning, it is dried to facilitate bonding with the new mask;

[0037] B. Stick the new mask material evenly on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com