Automatic filled road-bridge transitional attachment strap member

A technology of automatic filling and lapping, applied in bridge parts, roads, bridges, etc., can solve problems such as reducing the number of road repairs, and achieve the effect of reducing the impact on normal traffic, reducing the number of repairs, and reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The working principle of auto-filling road and bridge transitional slab components is as follows:

[0043] The working process of effectively eliminating and preventing subsidence after the soft ground pavement road bridge is docked is explained by using the bridge deck to the road surface to automatically fill the road and bridge transitional slab components.

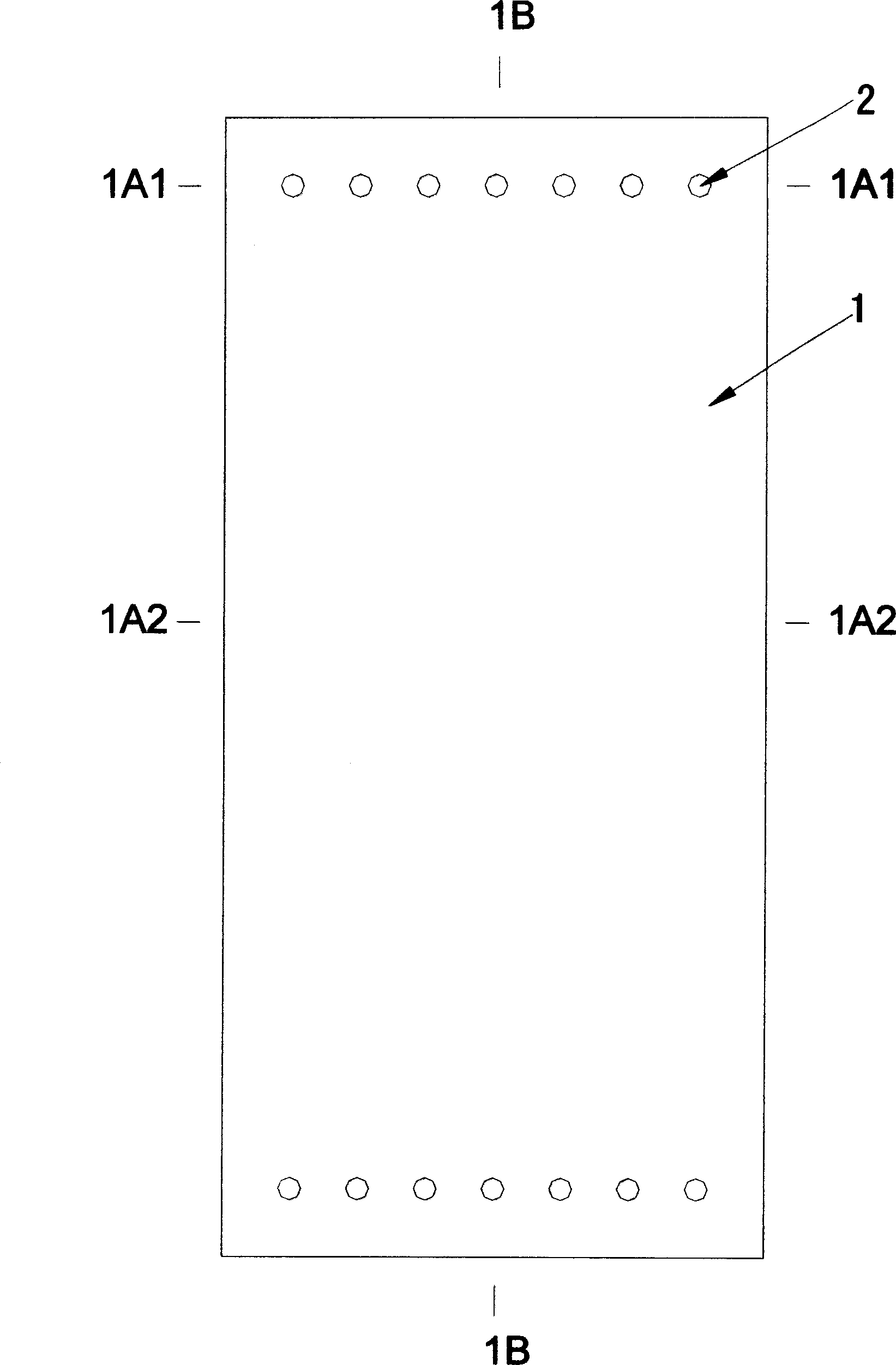

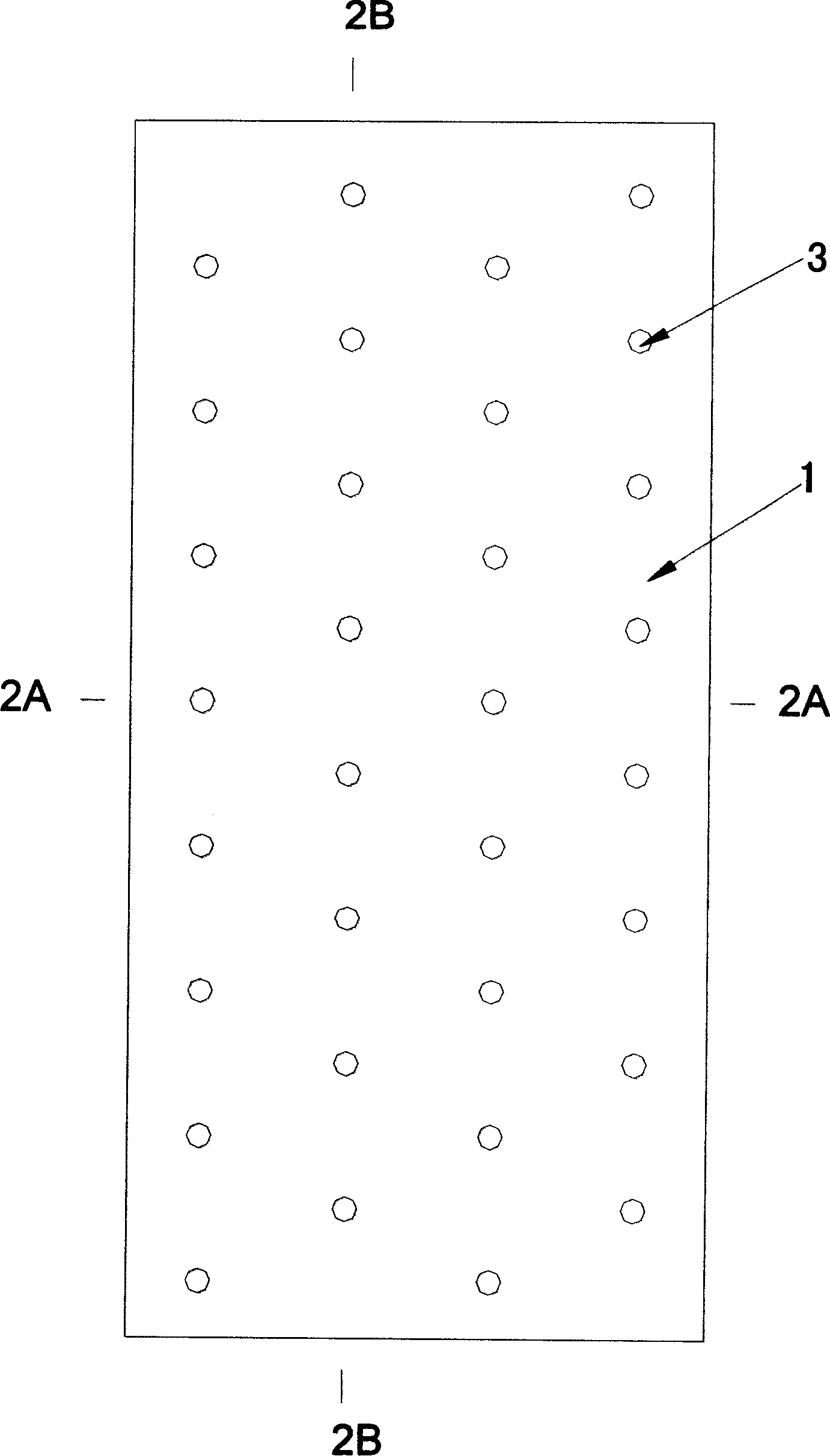

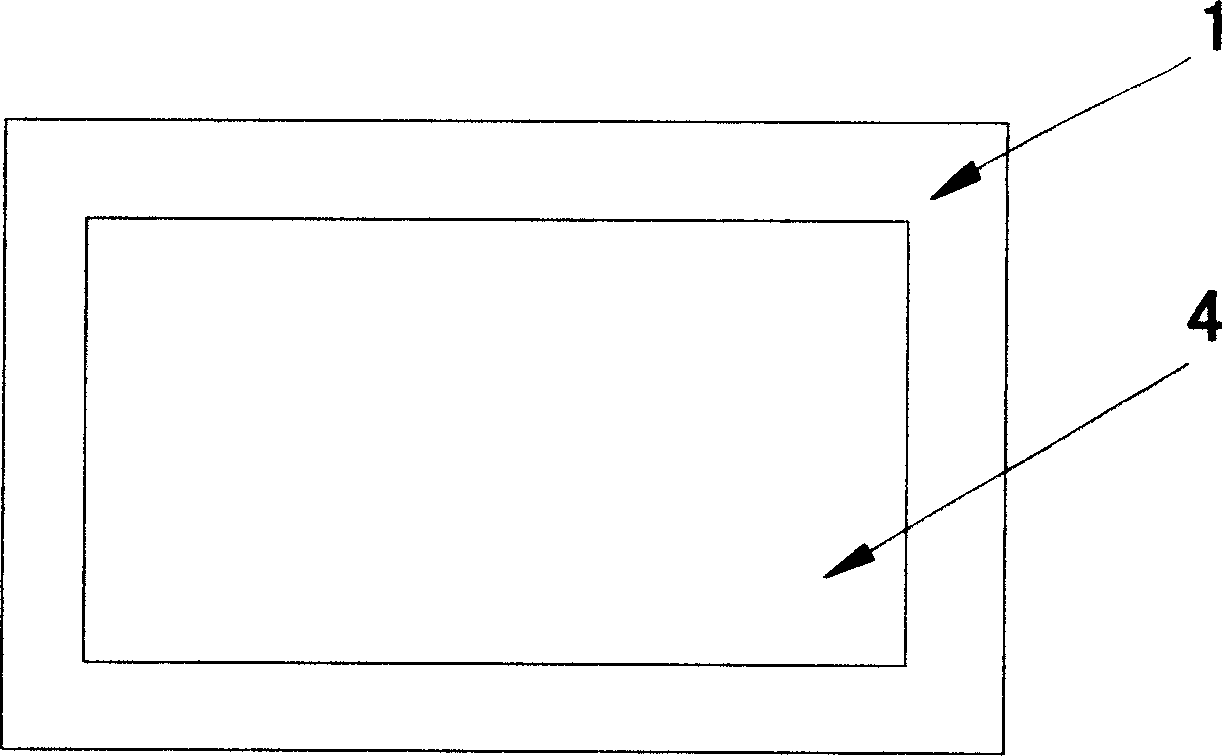

[0044] The board 1 on the transition section between the bridge deck 7 and the road surface 9 is the main part of the wrong platform, fracture, and vehicle jump caused by the settlement. The transition board 1 between the road surface 9 and the bridge deck 7 is changed to a new structure with automatic filling function, and the two ends of the transition board 1 with automatic filling function in the new structure are respectively connected by thermal expansion and cold contraction buffer pads 8 . The new structure has an automatic filling function. In the internal material storage chamber 4 of the transition bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com