Dual piezoelectric beam driven diaphram air pump

A dual piezoelectric and diaphragm technology, which is applied to pumps with flexible working elements, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as difficulty in meeting chip heat dissipation requirements, and achieve low power consumption. , The effect of large output flow and small side size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

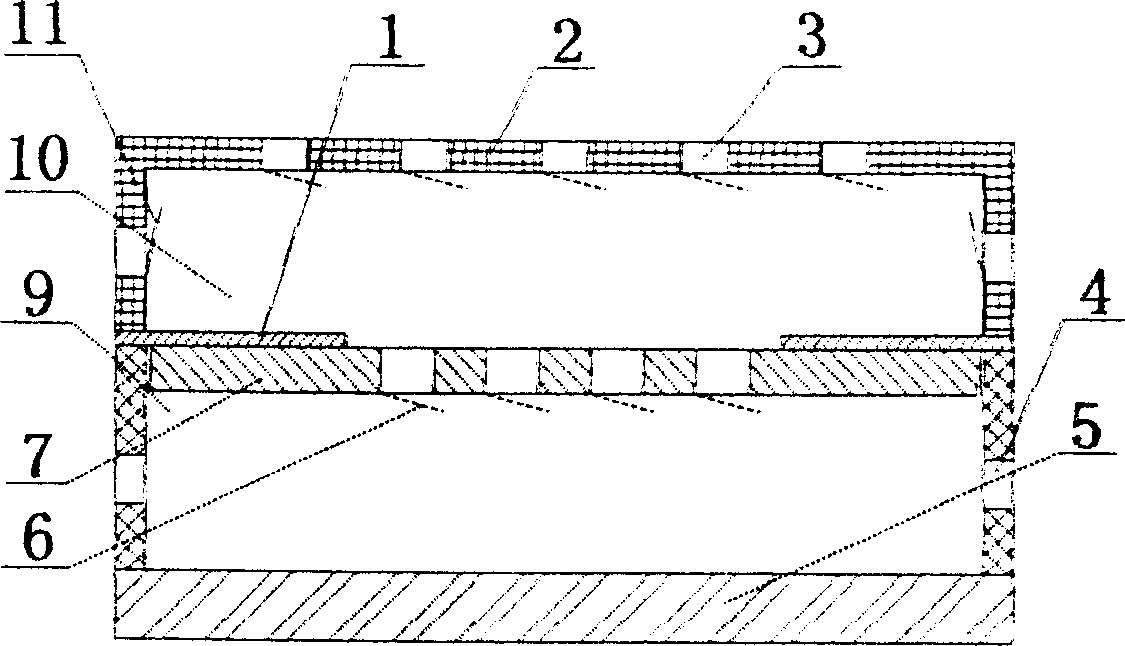

[0015] The difference between this embodiment and the previous embodiment is that a check valve 11 is added on the side of the upper chamber 10 (such as image 3 ). The advantage of this is that on the one hand, the flow rate of the upper chamber of the diaphragm air pump can be increased; on the other hand, when the one-way valve hole at the top of the upper chamber is blocked, the upper chamber can still be exchanged through the side check valve 11. gas. The structure, manufacturing and assembly methods of other parts of this embodiment are exactly the same as those of Embodiment 1, but the movement of the diaphragm should not interfere with the work of the one-way valve 11 during the manufacturing process.

Embodiment 3

[0017] The difference between this embodiment and the first embodiment is that the holes 4 on the side walls of the upper chamber 10 and the lower chamber 9 and the one-way valve 11 on the side of the upper chamber 10 can also be trapezoidal holes / trapezoidal valves. This kind of valve realizes the one-way flow of air flow by utilizing the different flow resistances in the two directions of the trapezoidal hole / trapezoidal valve. Its manufacturing process is simpler than that of the one-way valve with the valve plate, thus greatly increasing the reliability of the diaphragm air pump. sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com