Dual-scroll pump

A double volute and pump body technology, applied in the mechanical field, can solve problems such as damage pressure, bearing wear, and affecting the service life of volute pumps, and achieve the effect of prolonging service life and reducing radial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

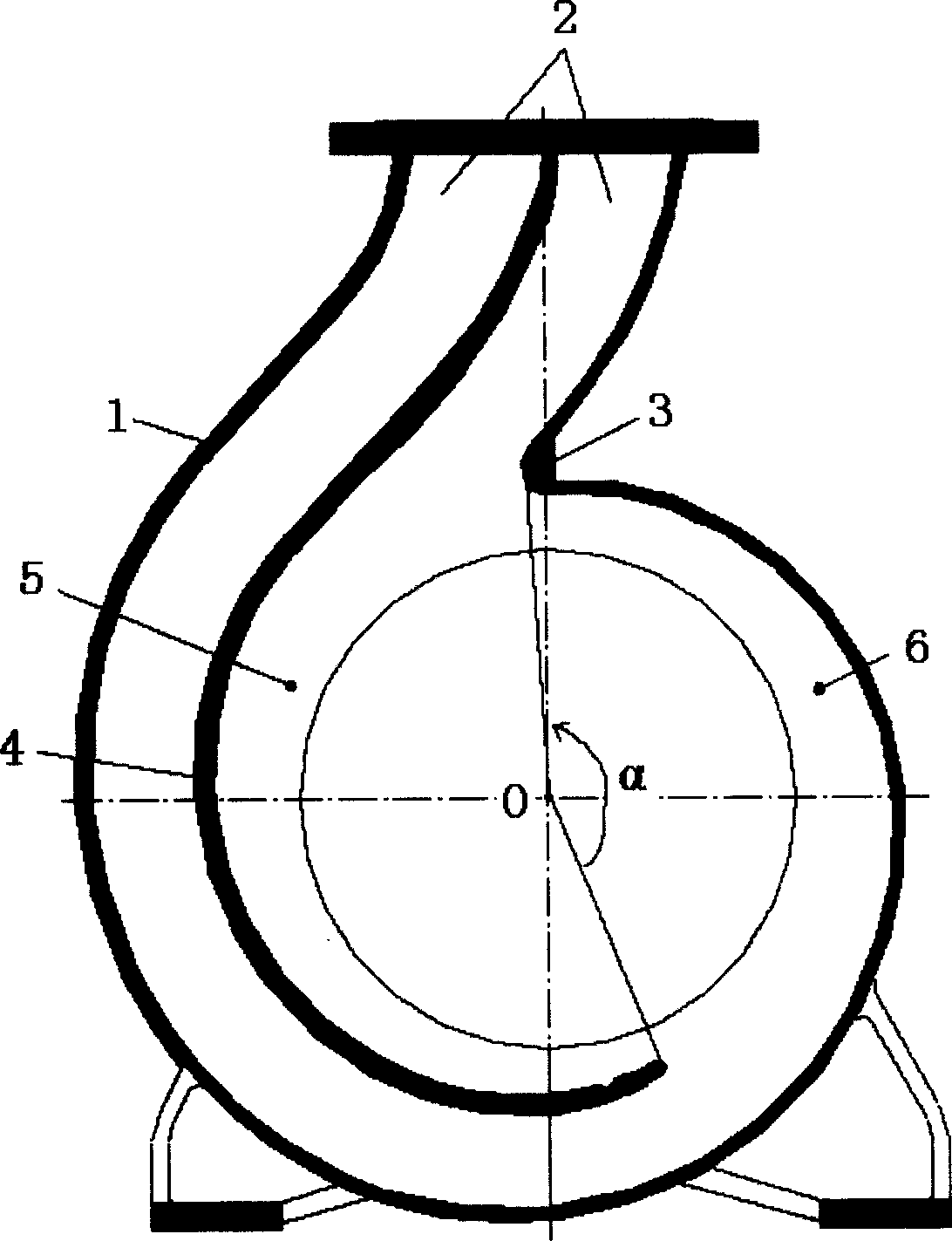

[0008] Such as figure 1 As shown, the double volute pump of the present invention is composed of a pump body 1, and a spiral extruding chamber is arranged in the pump body 1, and the extruding chamber is connected with a spiral flow channel 2. The upper side of the flow channel 2 has a partition tongue 3 protruding into the flow channel, wherein, the middle part of the flow channel 2 is provided with a partition plate 4 along the axial direction of the flow channel, and the partition plate 4 is arranged in a spiral Extending linearly to the extrusion chamber, the extrusion chamber is provided with blades (not shown in the figure), the connection line between the lower end point of the partition plate 4 and the rotation center of the blade 0 and the The included angle α of the line between the tongue 3 and the rotation center 0 of the blade is between 160° and 180°.

[0009] Further, a first cavity 5 is formed between the partition plate 4 and the vane, a second cavity 6 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com