Mask for continuously transverse solidifying technology and method for forming polycrystal silicon layer

A technology of lateral solidification and polysilicon thin film, which is applied in the field of masks and can solve problems such as poor electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

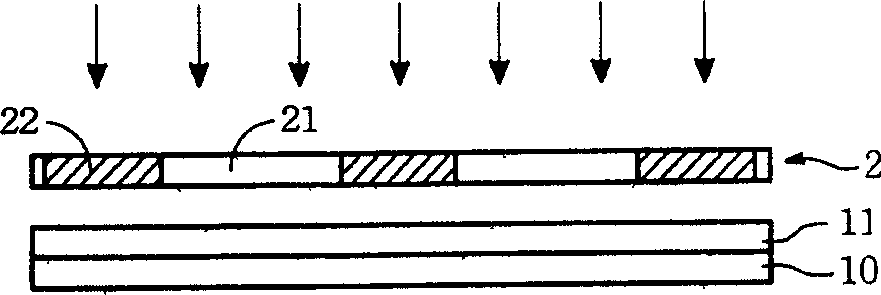

[0039] The invention discloses a mask applied to continuous lateral solidification (SLS) to produce a polysilicon film with dispersed crystal boundaries. The mask of the present invention will be described in detail below with reference to the accompanying drawings and multiple specific embodiments.

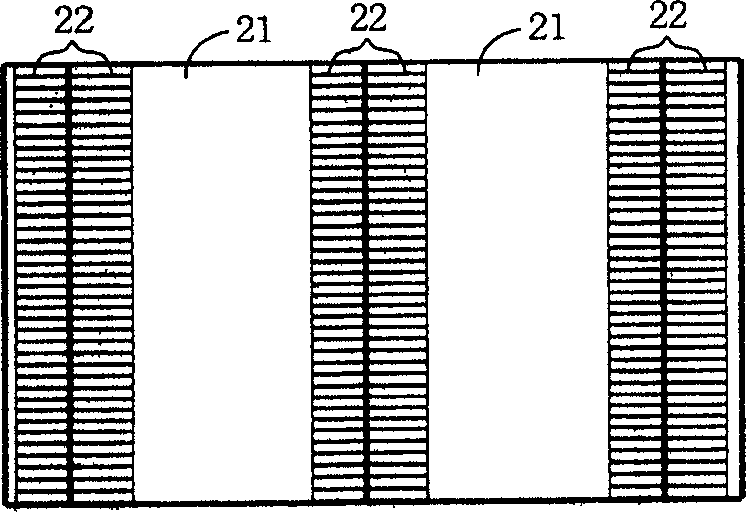

[0040] Such as figure 2 Shown is a schematic top view of a mask in a preferred embodiment of the present invention. figure 2 The mask 3 includes at least: a first area 31 , a second area 32 , and a third area 33 . Wherein, the first area 31 and the third area 33 are light-transmitting, and the second area 32 is light-shielding.

[0041] The first region 31 surrounds the second region 32 , and the first region 31 and the second region 32 have substantially the same peripheral shape. The third region 33 has the same peripheral shape as the first region 31 , and in this embodiment, the peripheral shapes of the above three regions are rectangular structures. Moreover, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com