Motor driven slide variable resistor

A motor drive and resistor technology, applied in the direction of the resistance element adjusted by the auxiliary drive device, can solve the problems of the quality level of the lossy device, the change of the moving speed of the motor drive, etc., achieve the effect of high quality level and reduce deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

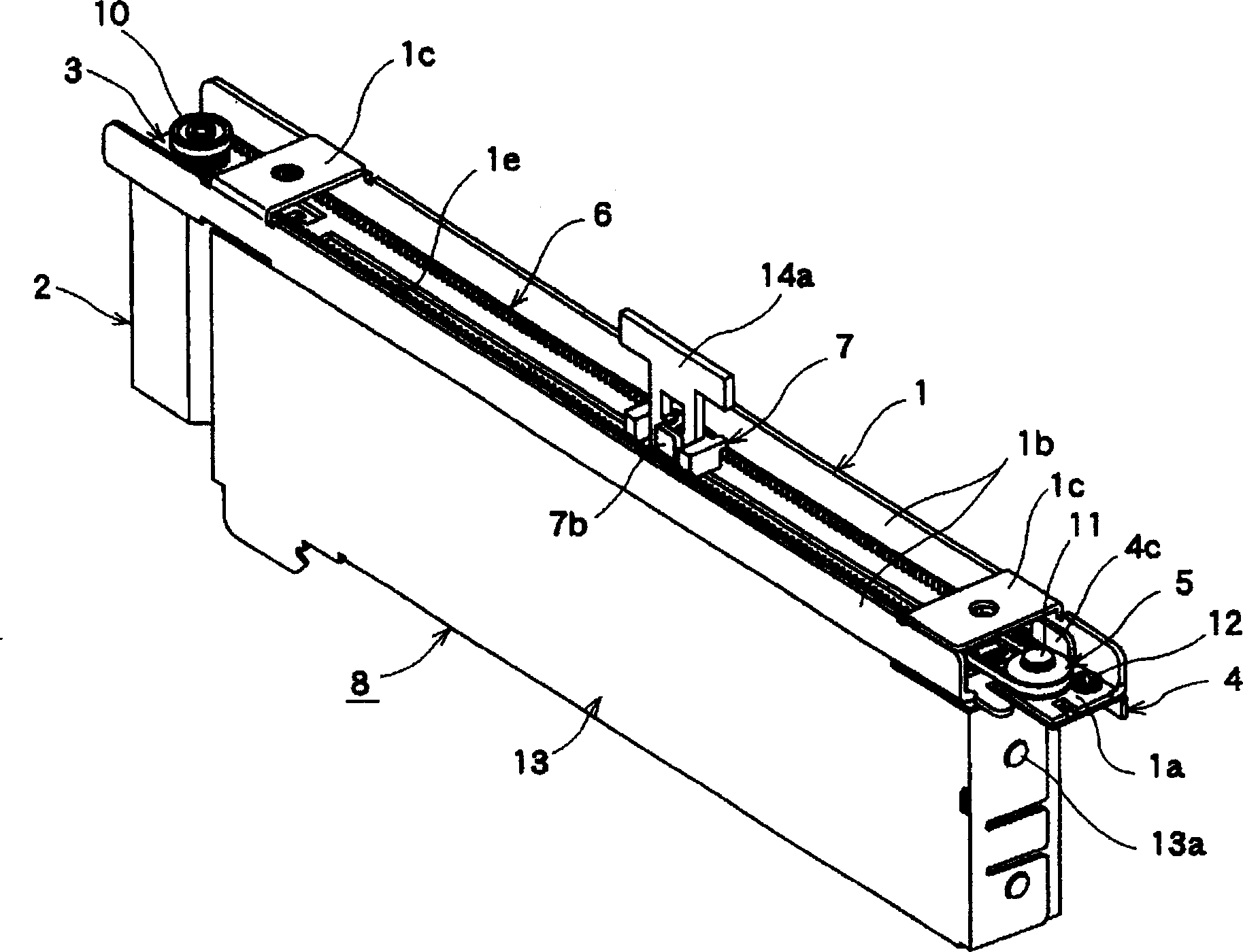

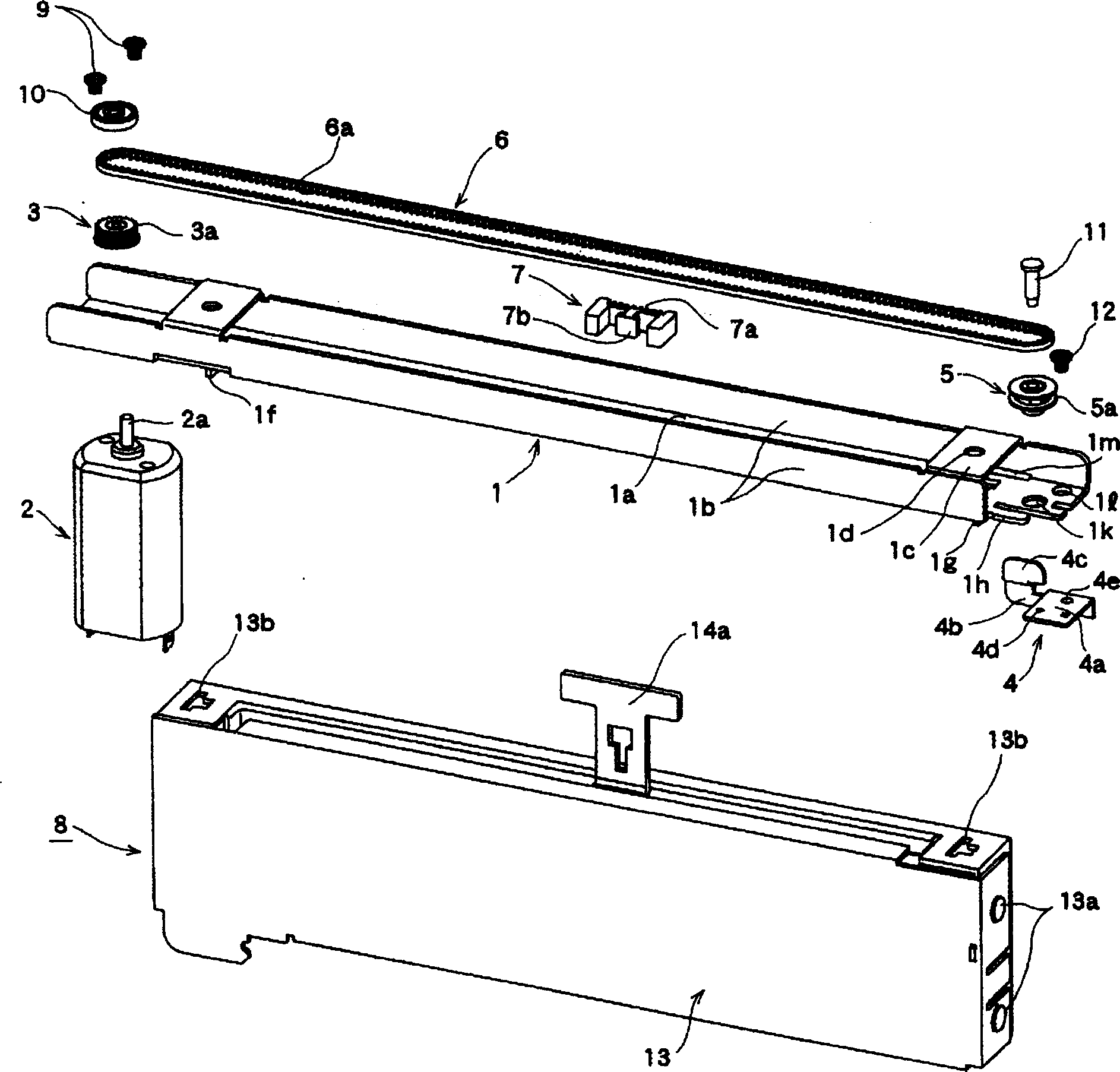

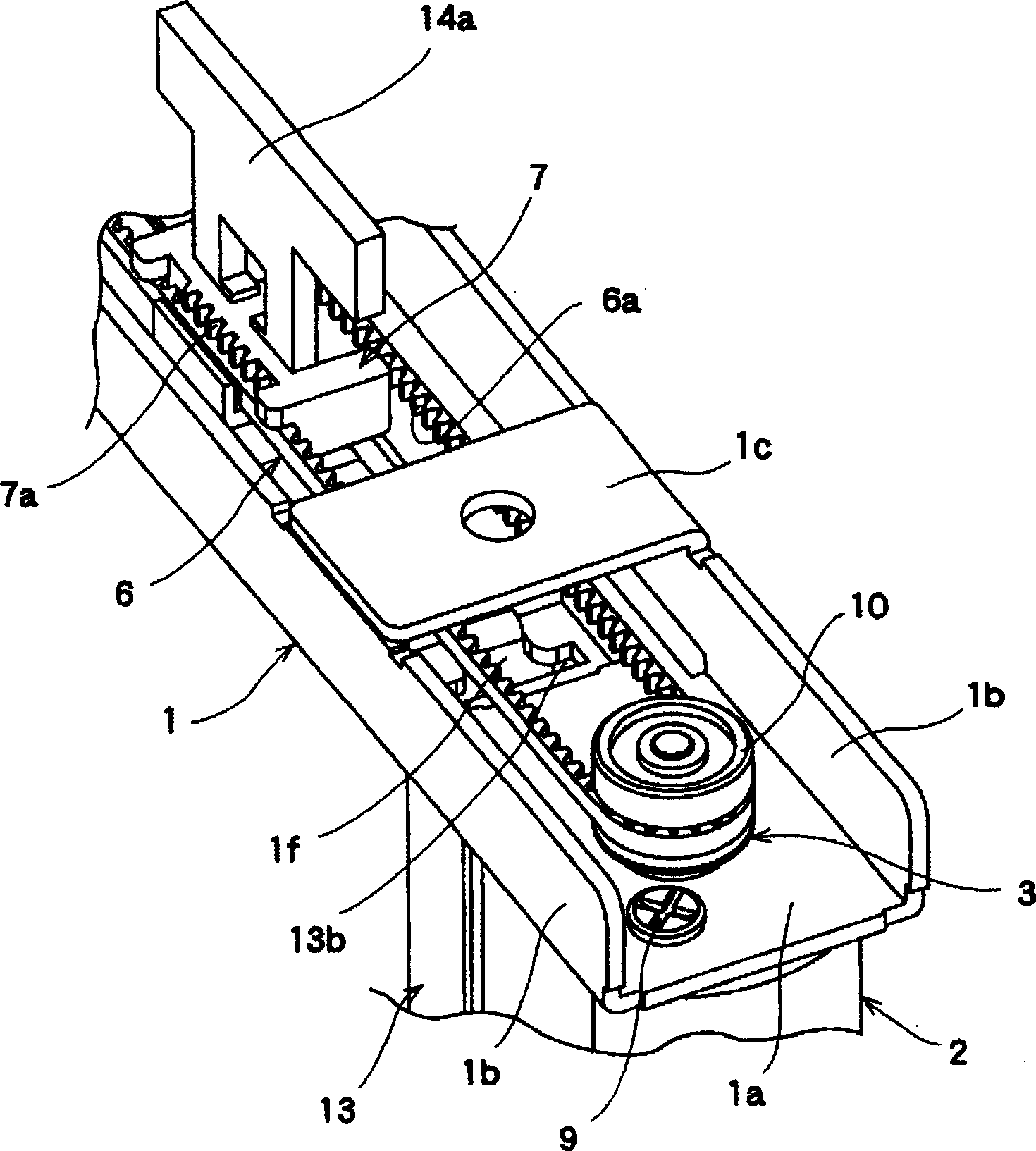

[0044] Below, the embodiments of the present invention are as Figure 1 to Figure 1 0 shown. figure 1 Is a perspective view showing the motor-driven sliding variable resistor of the present invention, figure 2 Is an exploded perspective view showing the motor-driven sliding variable resistor of the present invention, image 3 Is an enlarged perspective view of the motor side of the motor-driven sliding variable resistor of the present invention, Figure 4 It is an enlarged exploded perspective view of the motor side of the motor-driven sliding variable resistor of the present invention, Figure 5 It is an enlarged perspective view of the driven pulley side of the motor-driven sliding variable resistor of the present invention, Figure 6 It is an enlarged exploded perspective view of the driven pulley side of the motor-driven sliding variable resistor of the present invention, Figure 7 It is an explanatory diagram of the moving body and the variable resistor part moved to the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com