Crank gear for a reciprocating compressor

A crank drive and compressor technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as inaccurate balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

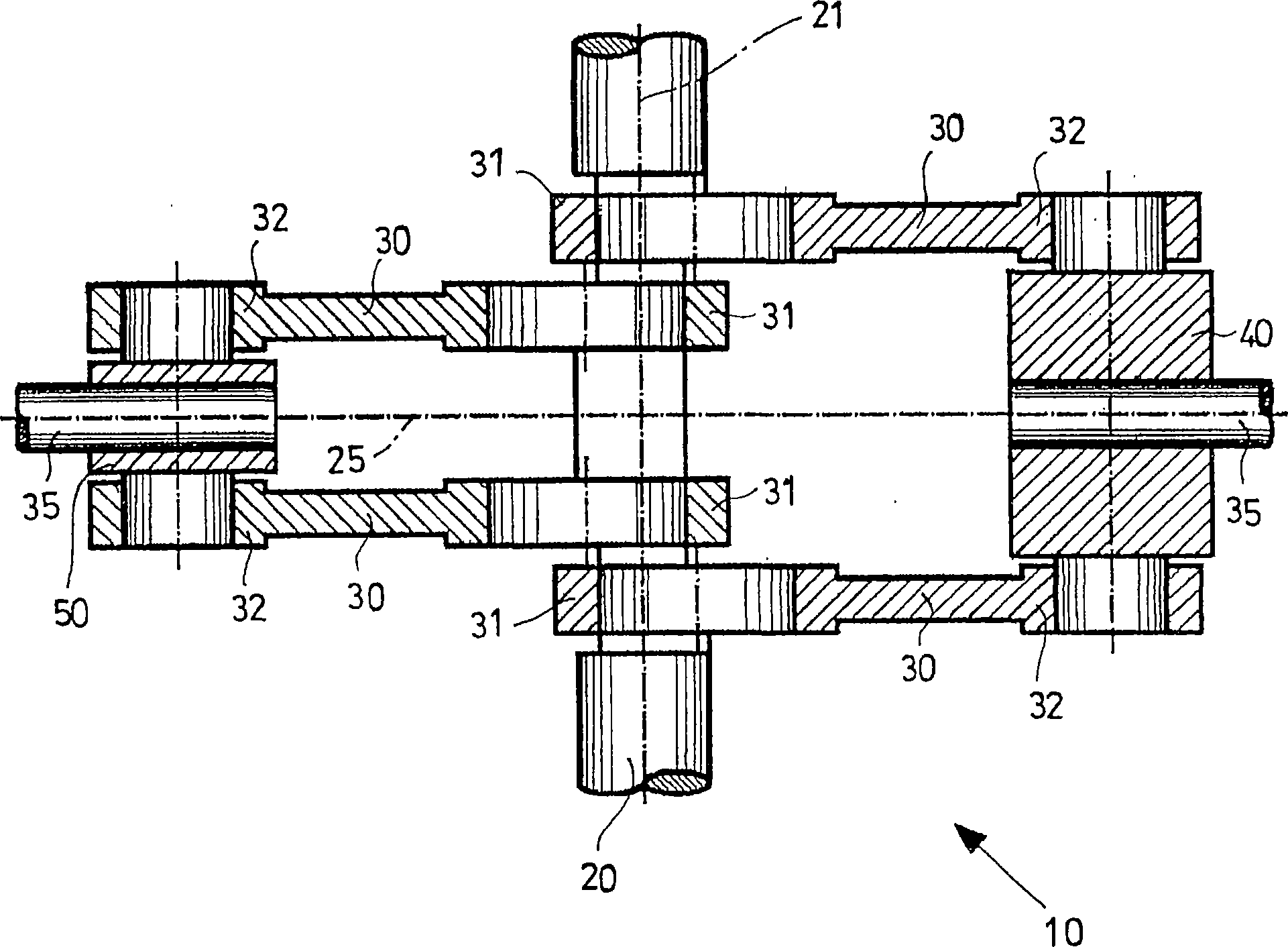

[0023] refer to figure 1 , which shows a crank gear 10 for a reciprocating compressor, on which a module can be applied comprising two working axes with two oppositely oriented cylinders? .

[0024] Said crank gear is adapted to constrain the two cylinders on the crank shaft 20 and keep them opposite each other with respect to the axis 21 of the shaft 20 .

[0025] The crank transmission 10 includes two rods 35 and a series of connecting rods 30, each connecting rod has its first end 31 connected to the shaft 20 and its second end 32 connected to one of the two rods 35. Each of the two rods 35 is respectively connected to one of the two cylinders.

[0026] The series of connecting rods 30 comprises identical connecting rods 30 arranged symmetrically with respect to the axis of alignment 25 of the two cylinders.

[0027] Furthermore, the connecting rods 30 of said series of connecting rods 30 are connected in pairs to two rods 35 by means of two crossheads 40 and 50 respecti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap