Light-negative moulding set

A backlight module and light source technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems affecting the display brightness and quality of the display panel, increasing the structural complexity of the backlight module, and the actual production difficulty of the light guide plate. The effect of light energy utilization, elimination of dark bands, and simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution will be described in further detail below in conjunction with the accompanying drawings.

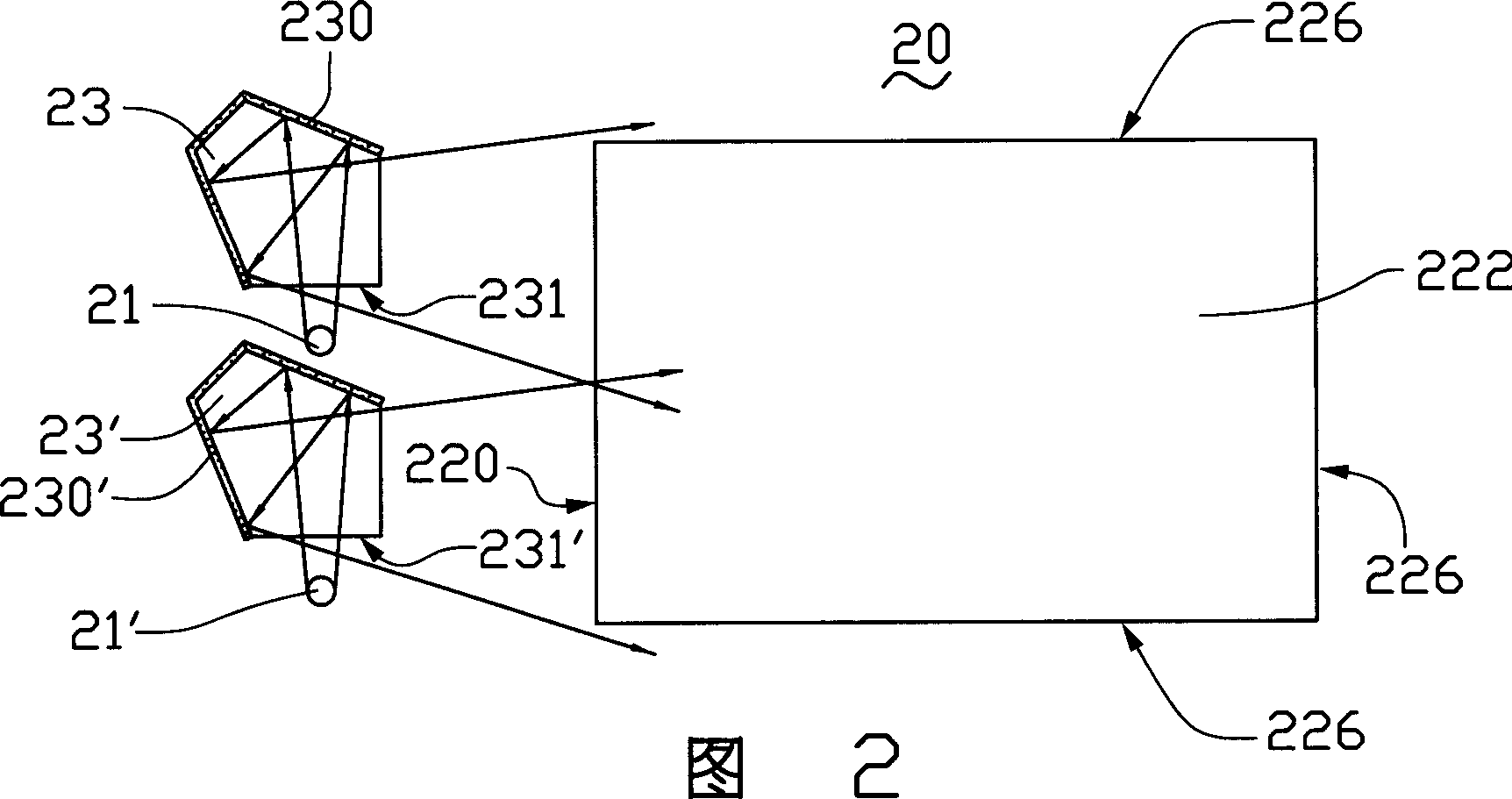

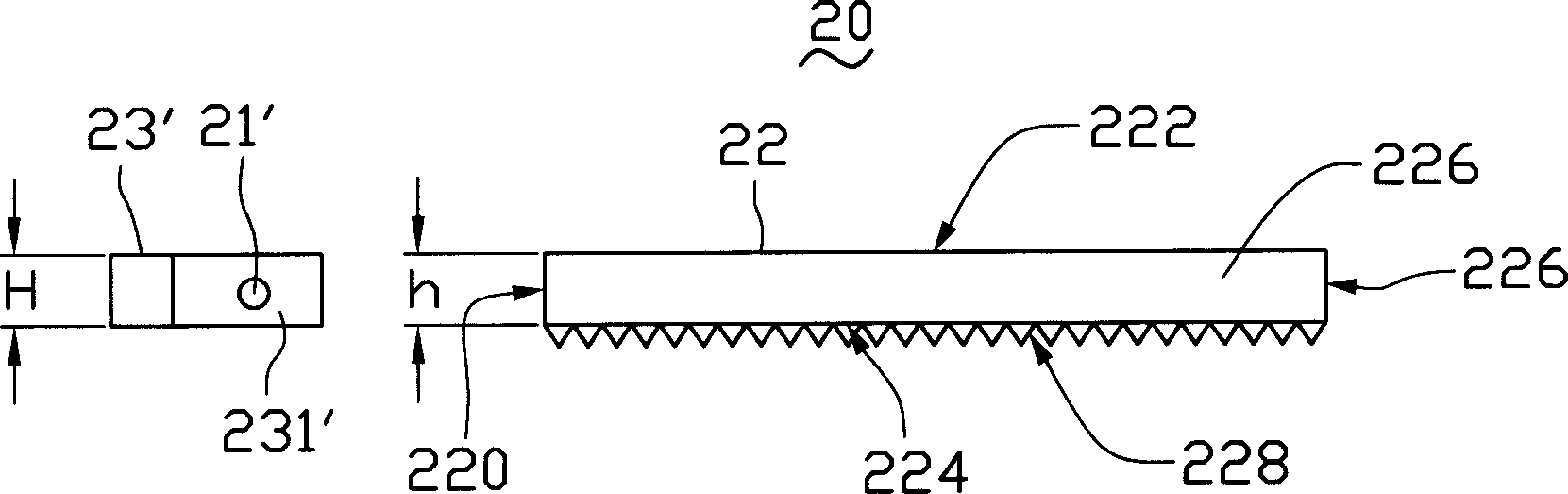

[0027] Please refer to Figure 2 and image 3 , is a schematic structural diagram of the backlight module provided in this embodiment. The backlight module 20 includes two light sources 21, 21', a light guide plate 22 and two multiple reflection devices corresponding to the light sources 21, 21'. Wherein, the multiple reflection device adopts pentagonal prisms 23, 23', and the two pentagonal prisms 23, 23' are located in the light path from the light beams emitted by the two light sources 21, 21' to the light guide plate 22.

[0028] Generally, the light source 21, 21' can be a point light source or a line light source, such as a fluorescent tube, a cold cathode lamp or a light emitting diode, etc. In this embodiment, two light emitting diodes are used as the two point light sources 21, 21'.

[0029] The light sources 21, 21' can be located on the same side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com