Drilling/feed drill/withdrawing drill sealing device for high pressure water rock layer and grouting withdrawing drill method

A sealing device, high-pressure water technology, applied in drilling equipment and methods, sealing/isolation, drilling equipment, etc., to achieve the effect of solving safe drilling, increasing safety factor, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The "connecting hand" described in this article is a connecting device for connecting two drill pipes, which is a general-purpose part.

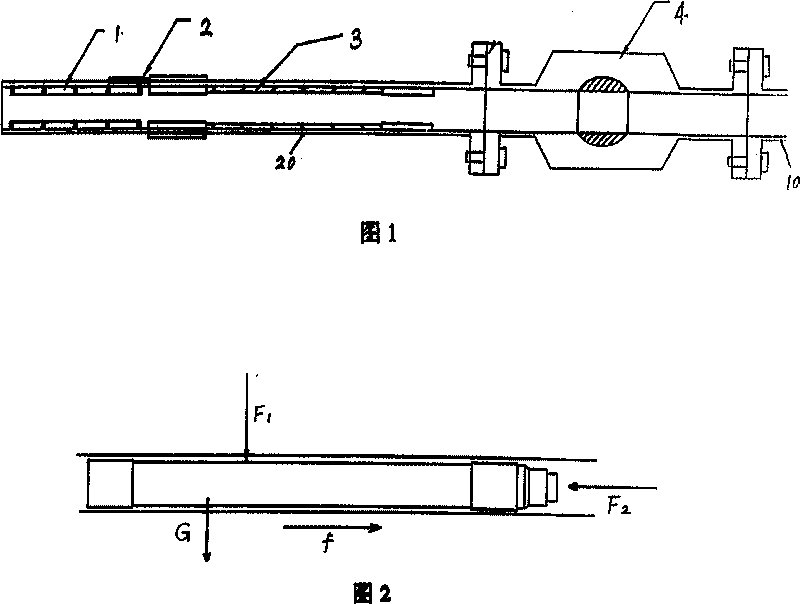

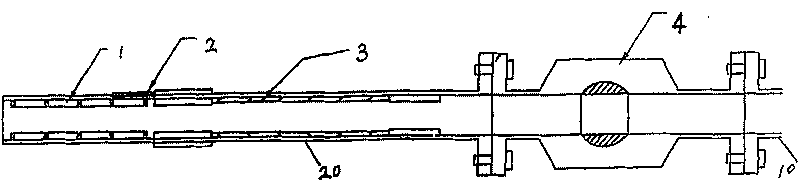

[0017] see figure 1 . In this paper, "hydraulic internal expansion sealing plug or air pressure internal expansion sealing plug" is abbreviated as "hydraulic (air) pressure internal expansion sealing plug".

[0018] The device of the present invention comprises an orifice tube rear section 10, further comprising:

[0019] The front section 20 of the orifice tube, the front section 20 of the orifice tube is provided with a sealing ring 1 and a pressure sealing device, and the pressure sealing device is a liquid (gas) pressure internal expansion sealing plug 3;

[0020] A high-pressure valve 4, one end of the high-pressure valve 4 is connected to the front section 20 of the orifice pipe through a flange, and the other end is connected to the rear section 10 of the orifice pipe through a flange.

[0021] The hydraulic (air) pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com