Converter for changing three phase power into single phase power

A technology of three-phase power supply and single-phase power supply, applied in the direction of circuit devices, electrical components, AC network circuits, etc., can solve the problems of three-phase power supply grid power imbalance, grid power supply deterioration, damage, etc., to achieve reasonable and effective use , Ensure safe and efficient operation, simple and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

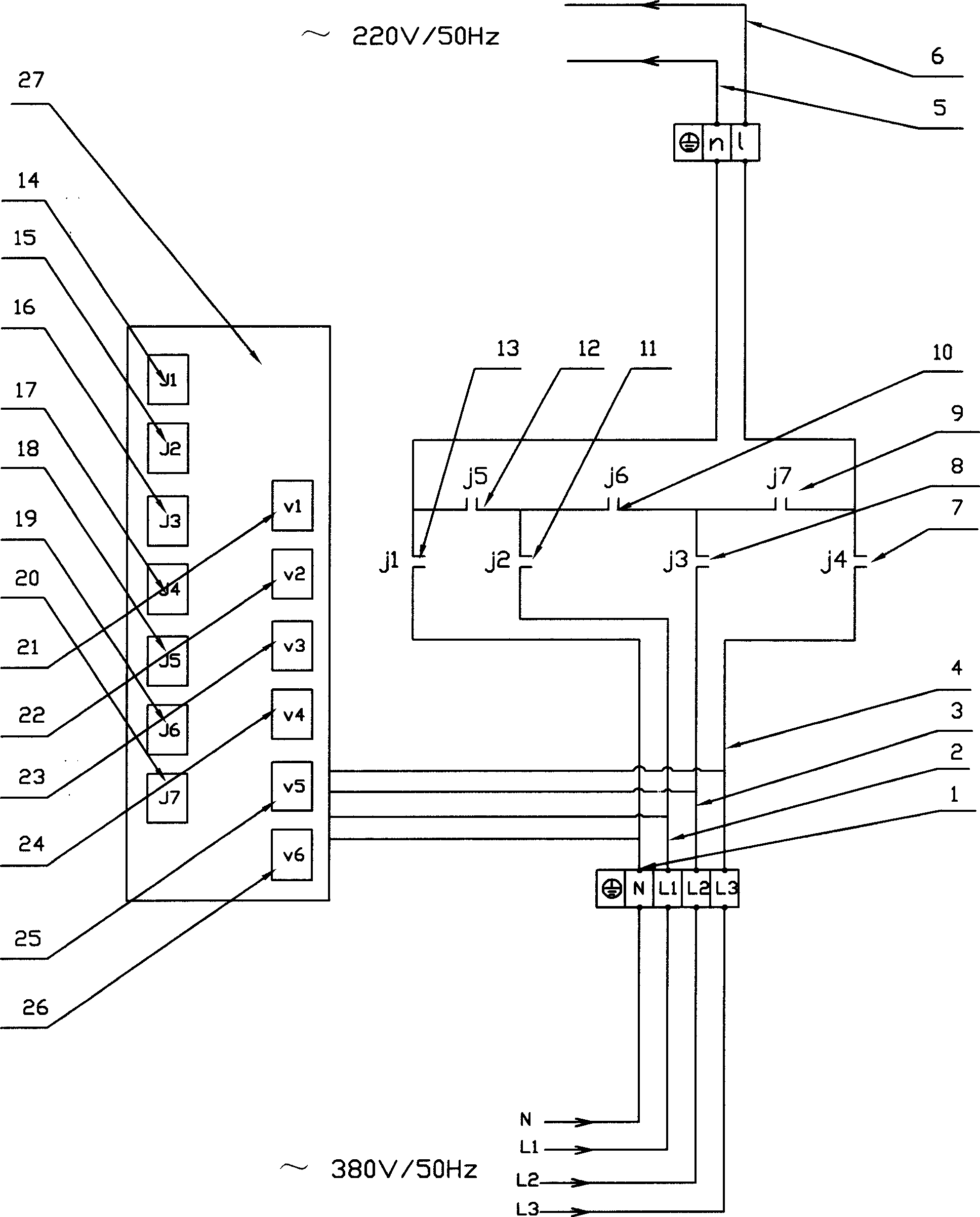

[0016] Embodiment 1, with reference to figure 1 . A three-phase power-to-single-phase power conversion device, comprising three-phase power input lines N(1), L1(2), L2(3), L3(4), single-phase power supply output lines n(5), l(6), voltage processor (27), main relay J1(14), J2(15), J3(16), J4(17), J5(18), J6(19), J7(20), voltage Transformers V1(21), V2(22), V3(23), V4(24), V5(25), V6(26), the voltage transformers V1(21), V2(22), V3(23 ), V4(24), V5(25), V6(26) and main relays J1(14), J2(15), J3(16), J4(17), J5(18), J6(19), J7 (20) Distributed on the voltage processor (27), the input lines N(1), L1(2), L2(3), and L3(4) of the three-phase power supply are respectively connected to the voltage processor (27) by wires , provide the driving power of the voltage processor (27), and make the input terminals of the voltage transformer V1 (21) be connected with the input lines N (1) and L1 (2) of the three-phase power supply respectively, and the voltage transformer V2 (22 ) input te...

Embodiment 2

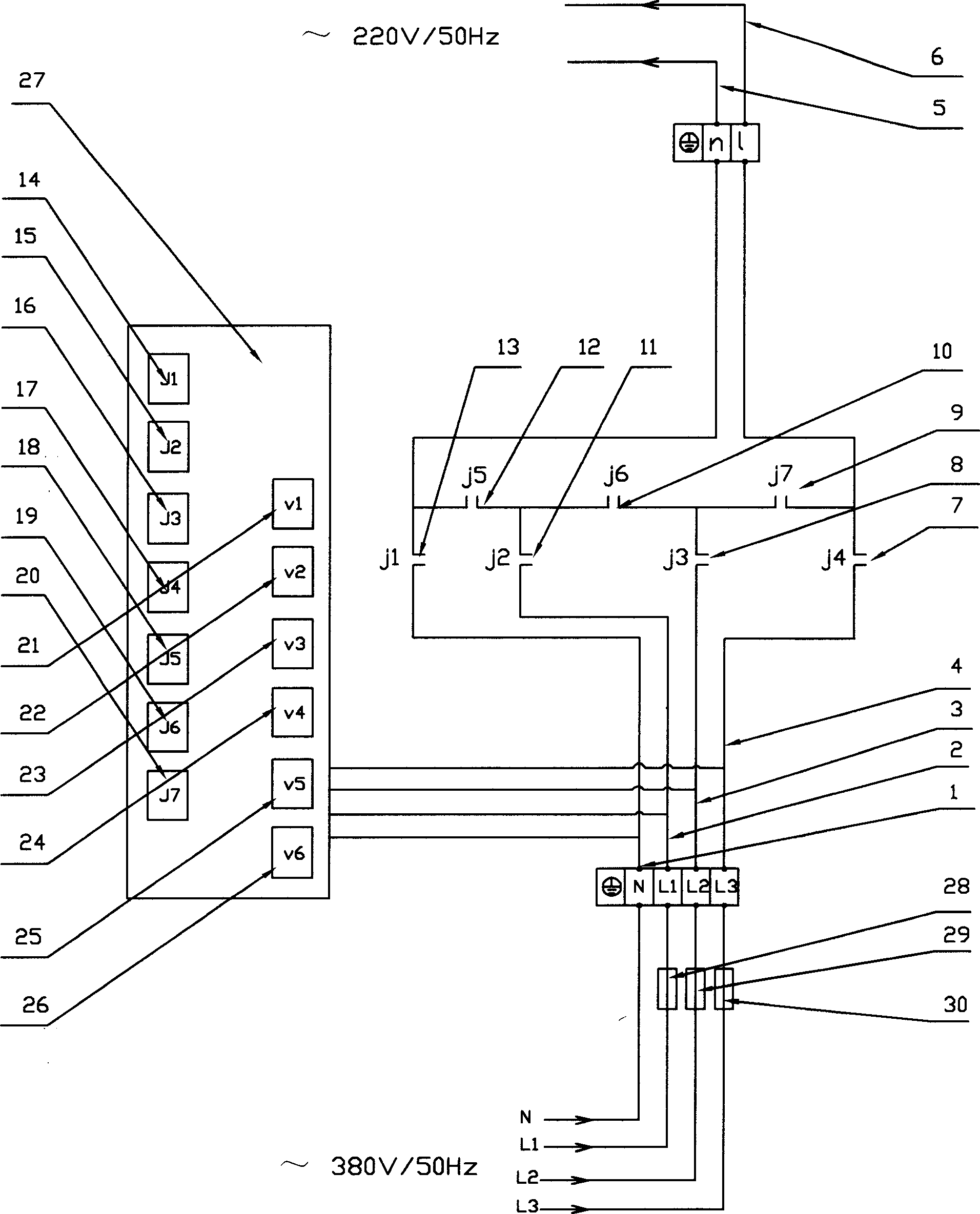

[0018] Embodiment 2, with reference to attached figure 2 . The difference between Embodiment 2 and Embodiment 1 is that fuses (28) and (29 ), (30) or leakage switch.

Embodiment 3

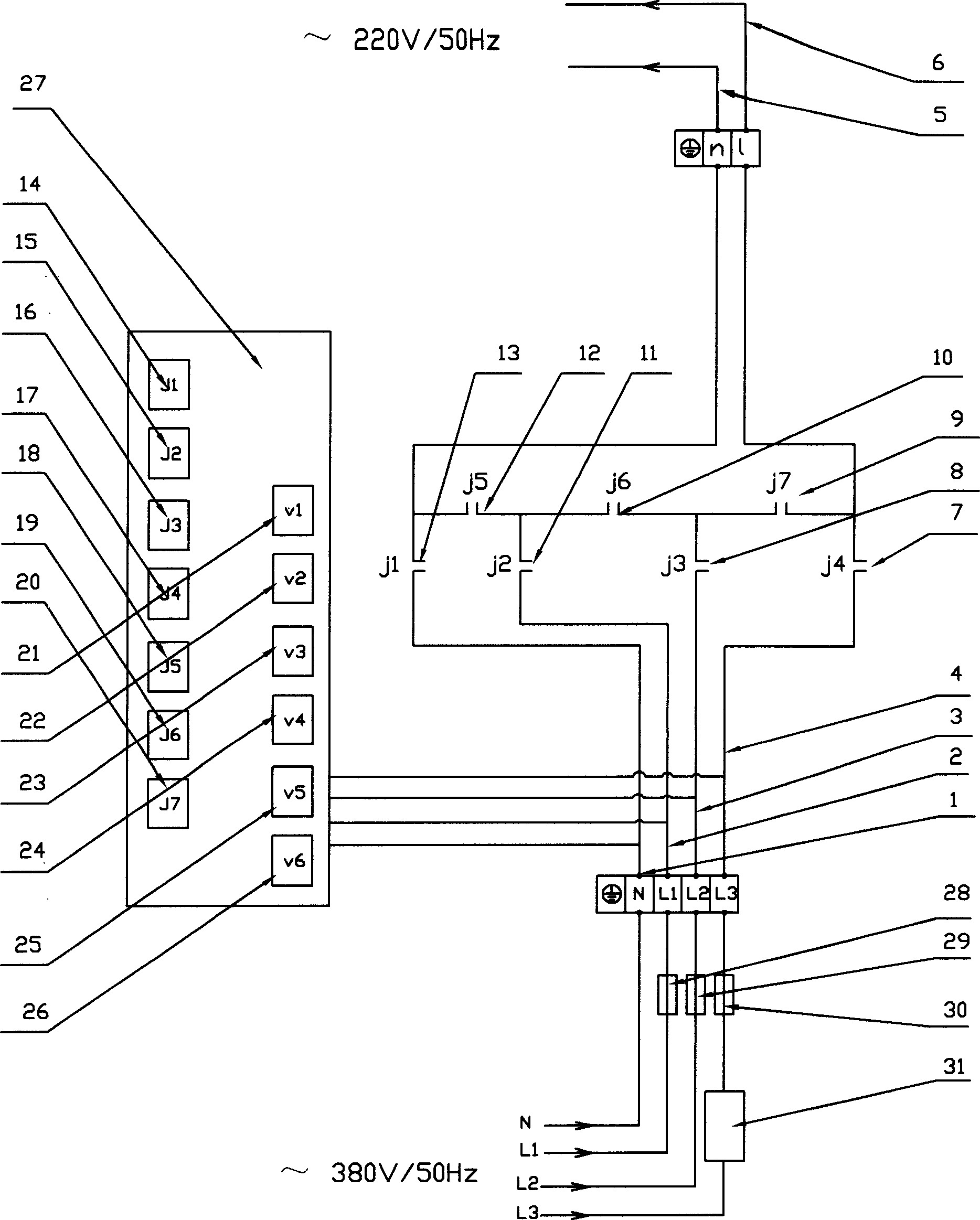

[0019] Embodiment 3, with reference to attached image 3 . The difference between embodiment 3 and embodiment 2 is that: on the input lines L1(2), L2(3), and L3(4) of the three-phase power supply, a phase line can be arbitrarily selected to add a voltage-reducing transformer (31 ) or other voltage-reducing devices, the driving power supply of the voltage processor (27) cannot adopt the power supply after the voltage reduction.

[0020] The working principle is as follows: when the voltage between the input lines L1(2), L2(3), L3(4) and N(1) of the three-phase power supply is higher than the output lines n(5), l(6) of the single-phase power supply ) requirements, by selecting the phase line of the transformer (31) for step-down voltage, it is easy to meet the requirements for the use of the output lines n(5), l(6) of the single-phase power supply; when the input line L1(2) of the three-phase power supply ), the voltage between L2(3), L3(4) and N(1) is lower than the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com