Radial valve orificing axial hydraulic pressure plunger pump

A hydraulic column and axial technology, applied in variable capacity pump parts, parts of pumping devices for elastic fluids, pumps, etc., can solve the problem of difficult maintenance and replacement of valve body accessories, inconvenient maintenance and replacement, Easy to wear and fail and other problems, to achieve the effect of shortening maintenance time, reducing structural size and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

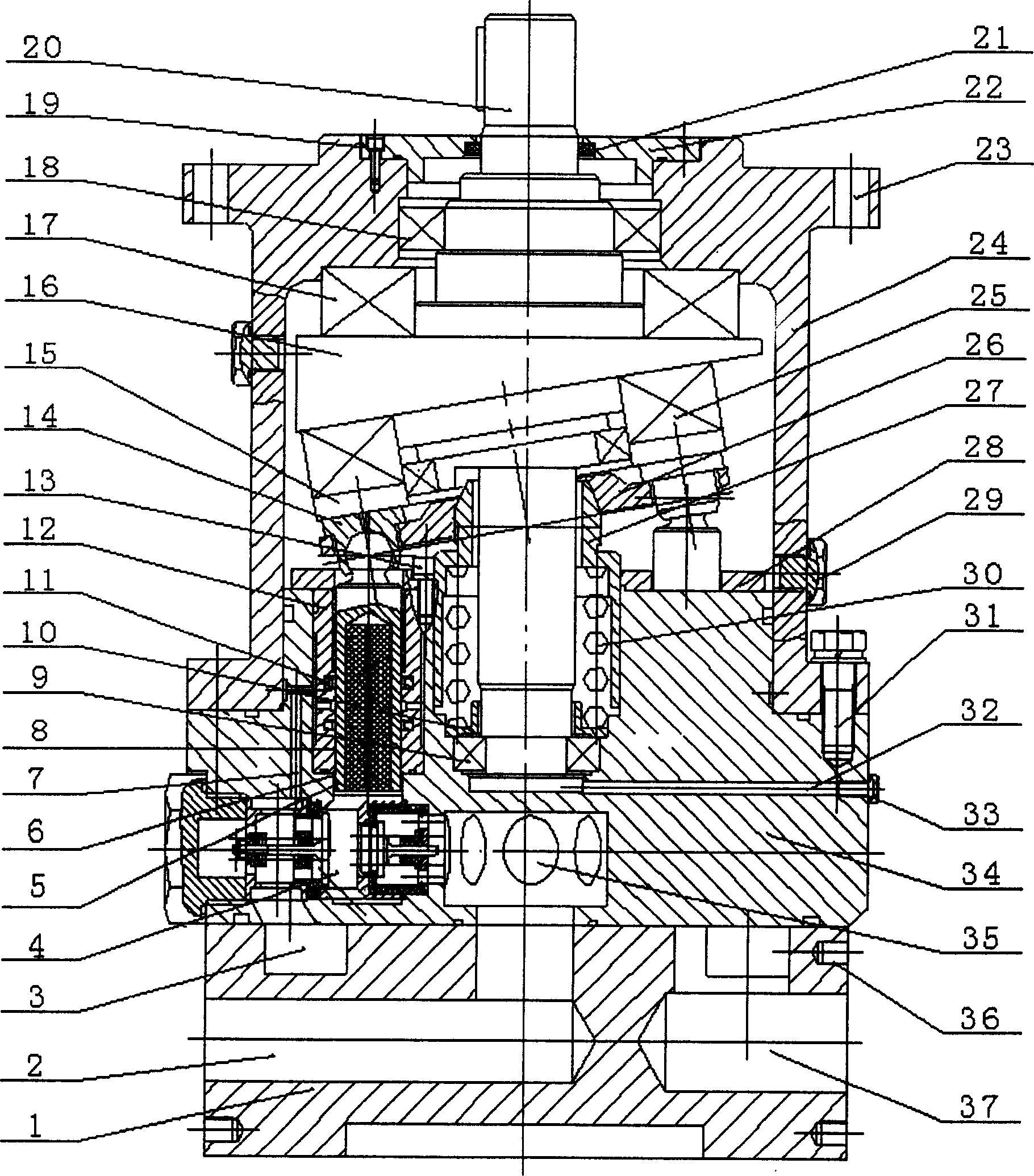

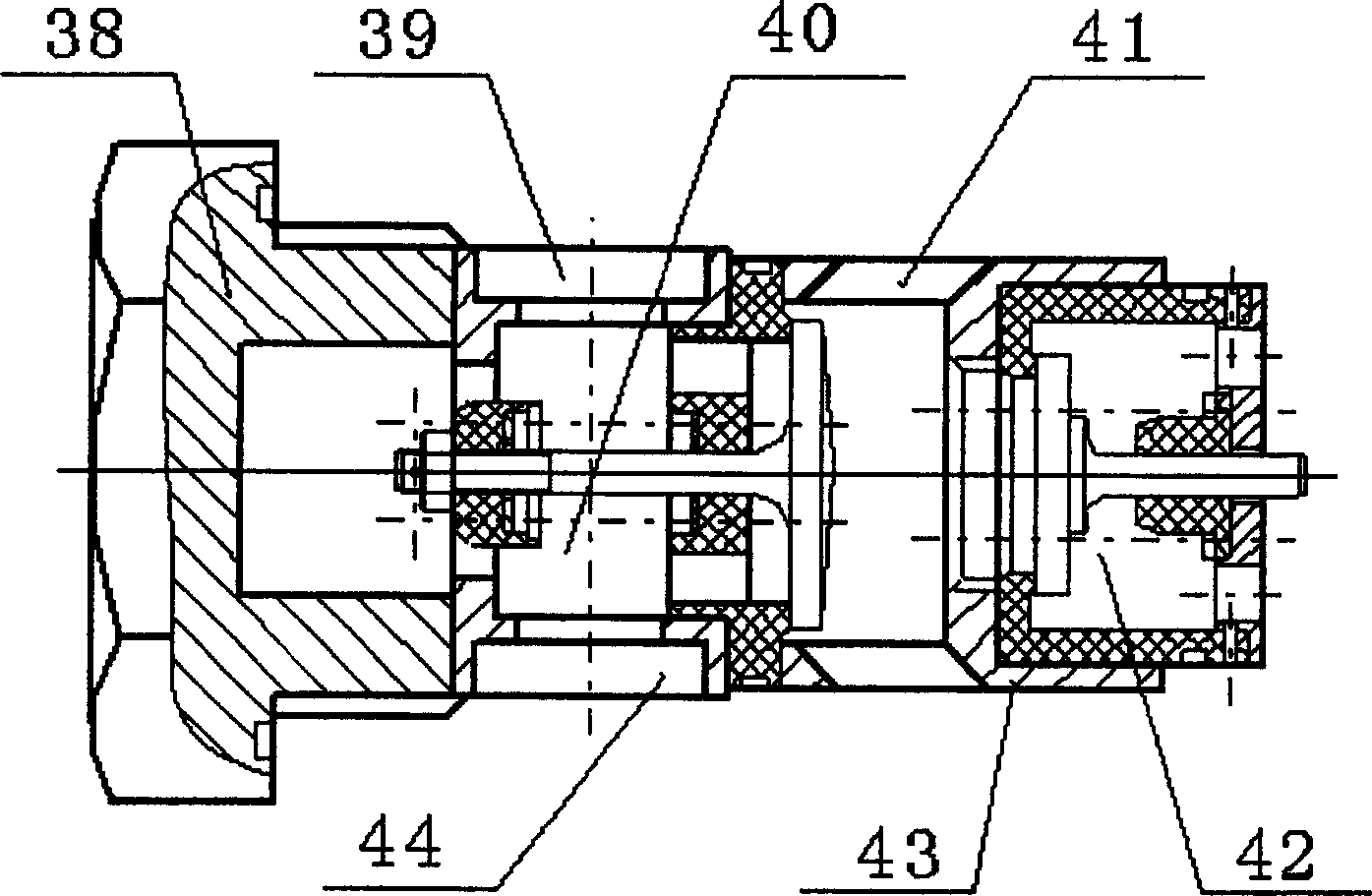

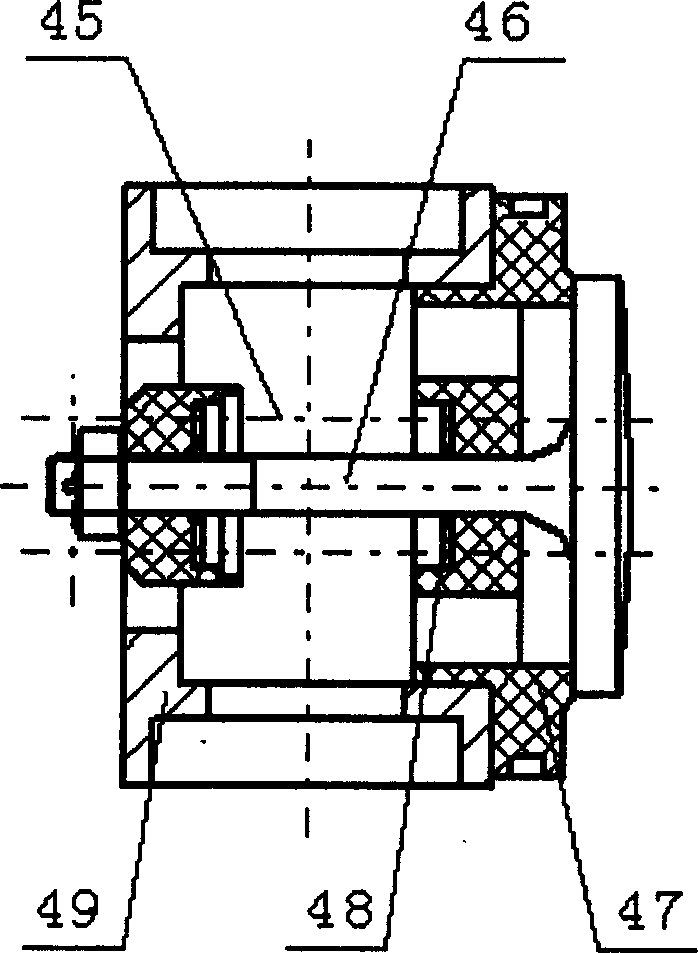

[0022] refer to Figure 1 ~ Figure 4 , the labels in the figure are: rear end cover 1, water outlet 2, annular groove 3, distribution valve body 4, plunger 5, plunger hole 6, water diversion channel 7, friction surface 8, deep groove ball bearing 9, spring seat 10. Rubber-plastic composite seal 11, plunger sleeve 12, compression screw 13, sliding shoe 14, swash plate 15, main shaft disc 16, thrust bearing 17, angular contact ball bearing 18, front end cover screw 19, main shaft 20, Oil seal ring 21, front end cover 22, positioning hole 23, pump body 24, ball bearing 25, return plate 26, ball hinge 27, pressure plate 28, screw plug 29, center spring 30, positioning screw 31, sewage outlet 32, plug 33. Cylinder body 34, central concave hole water outlet 35, screw hole 36, water inlet 37, distribution valve nut 38, suction valve port 39, suction valve 40, distribution valve port 41, pressure outlet valve 42, middle sleeve 43 , Suction valve inlet 44, Suction valve spring 45, Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com