Swashplate rotary axial piston pump with built-in valve distribution

An axial piston pump and rotary technology, applied in the field of hydraulic pumps, can solve the problems of complex and difficult distribution valve group layout, high requirements for oil filtration accuracy, and complex cylinder processing, so as to improve hardness, fast response, and increase resistance. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings.

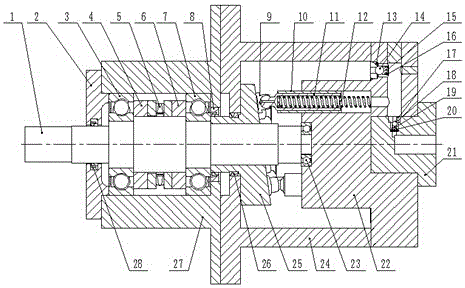

[0026] Such as figure 1 As shown, a swash plate rotary type internal valve distribution axial piston pump of the present invention includes a front end cover 2, a front pump body 27, a pump shaft arranged in the front pump body 27, and a bearing installed on the pump shaft 1. Components, sealing components, rear pump body 24, swash plate 25 installed in rear pump body 24, plunger shoe assembly, return spring 12, cylinder block 22, suction valve assembly installed in cylinder block 22, rear end cover 21. And an extrusion valve set installed in the rear end cover 21; wherein the front end cover 2, the front pump body 27, the rear pump body 24, the cylinder 22 and the rear end cover 21 are fixedly connected in sequence; the plunger The shoe assembly is placed in the plunger hole inside the cylinder 22; the swash plate 25 is connected to the pump shaft 1 through splines, so that the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com