Online evaluation and prediction method for calendar lifespan of steam turbine high-temperature durable parts

A steam turbine, life-span technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

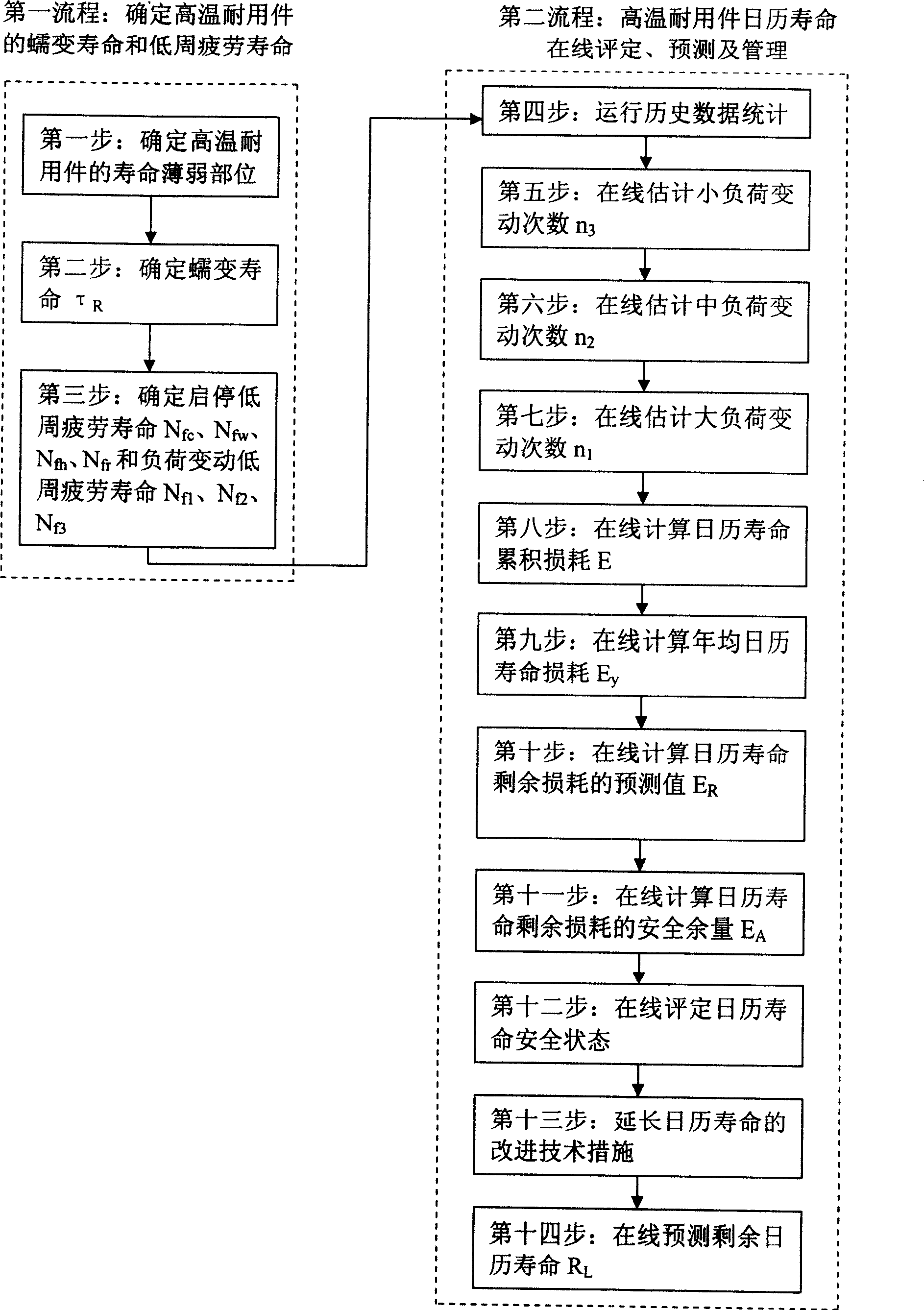

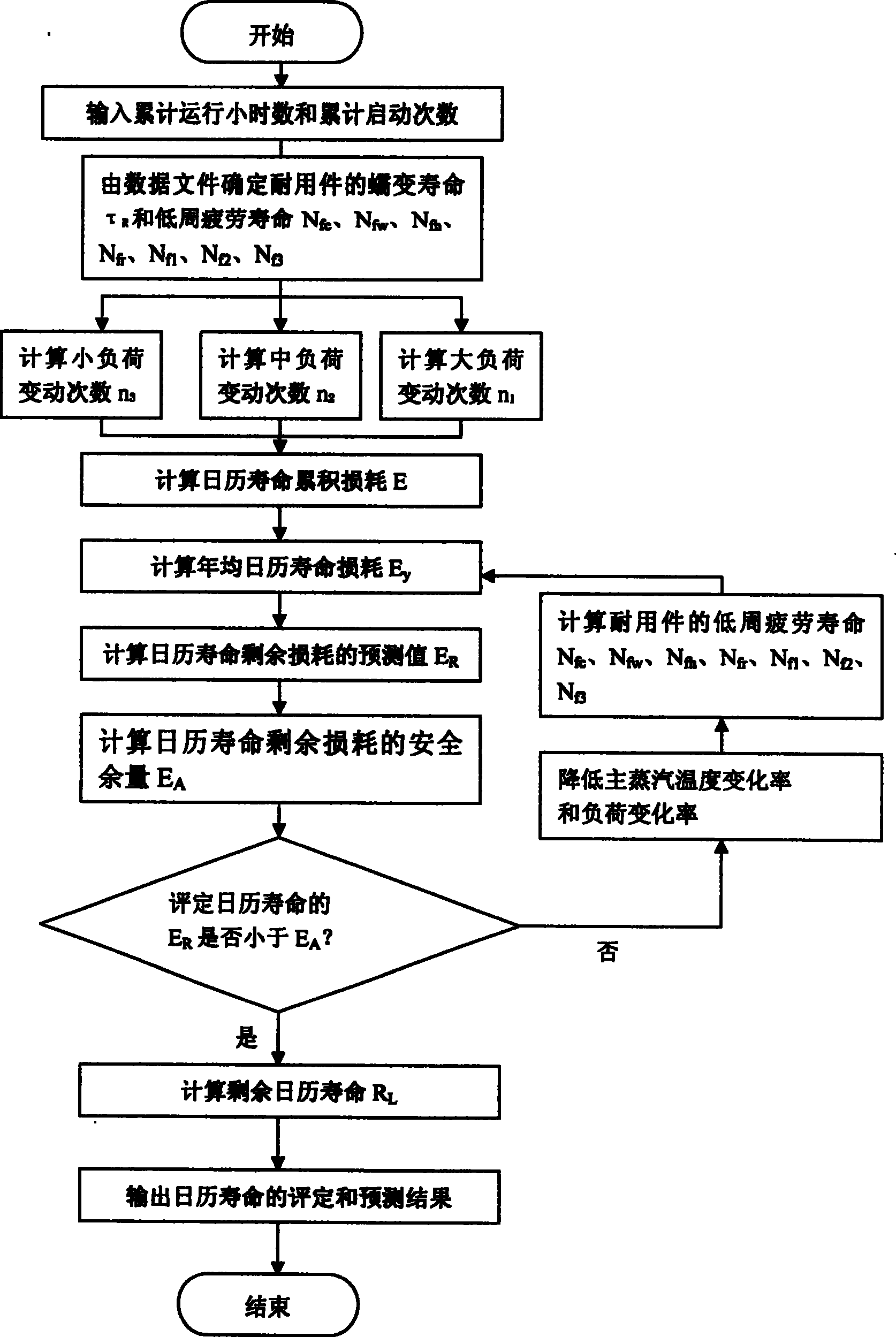

[0045] For a certain type of high-pressure rotor of a supercritical 600MW steam turbine whose main steam temperature and reheat steam temperature are 566°C, adopt figure 1 The shown flow chart of the method provided by the present invention adopts C language to write calculation software, and runs on the computer of steam turbine parameter monitoring and control, such as figure 2 Shown is the computer software block diagram of the method of the present invention, which evaluates and predicts the calendar life of the high-pressure rotor of the steam turbine on-line.

[0046] Step 1: The operating temperature of the fillet on the rear outer surface of the impeller of the high-pressure rotor of the steam turbine regulating stage is 514.7°C, which exceeds 500°C. There is stress concentration at the fillet, which is the weakest part of the life of the high-pressure rotor of the steam turbine;

[0047] Step 2: The creep life of the weak part of the high-pressure rotor of the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com