Life Envelope Extension Method for Corrosion Fatigue Key Parts of Aircraft Structure

A technology for aircraft structure and corrosion fatigue, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low structural safety life and reduced structural fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

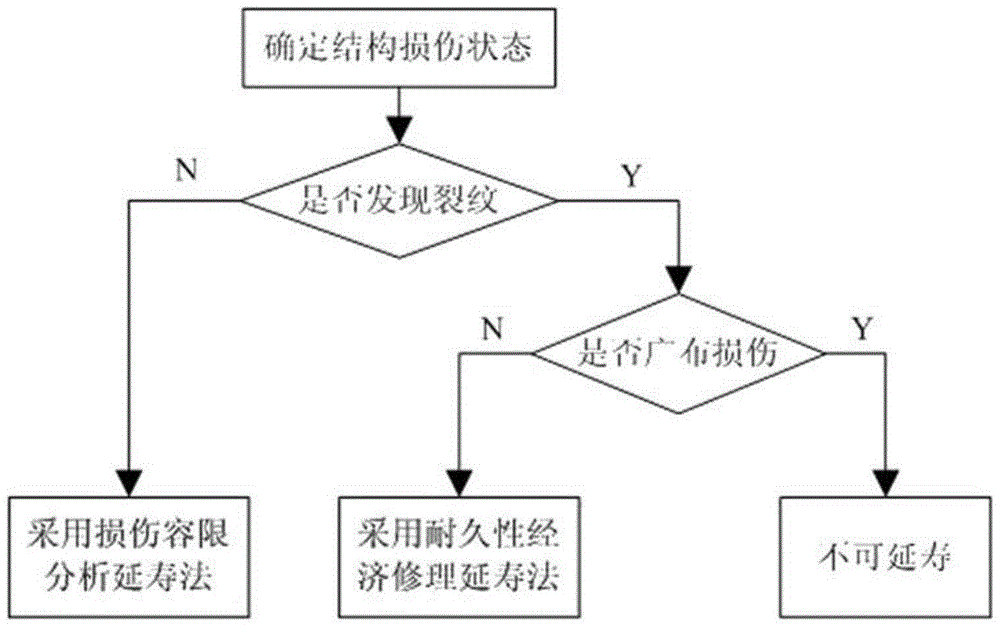

[0094] Refer below Figure 4 , which describes in detail the life envelope extension method of the present invention for prolonging the life of key aircraft structural corrosion fatigue components.

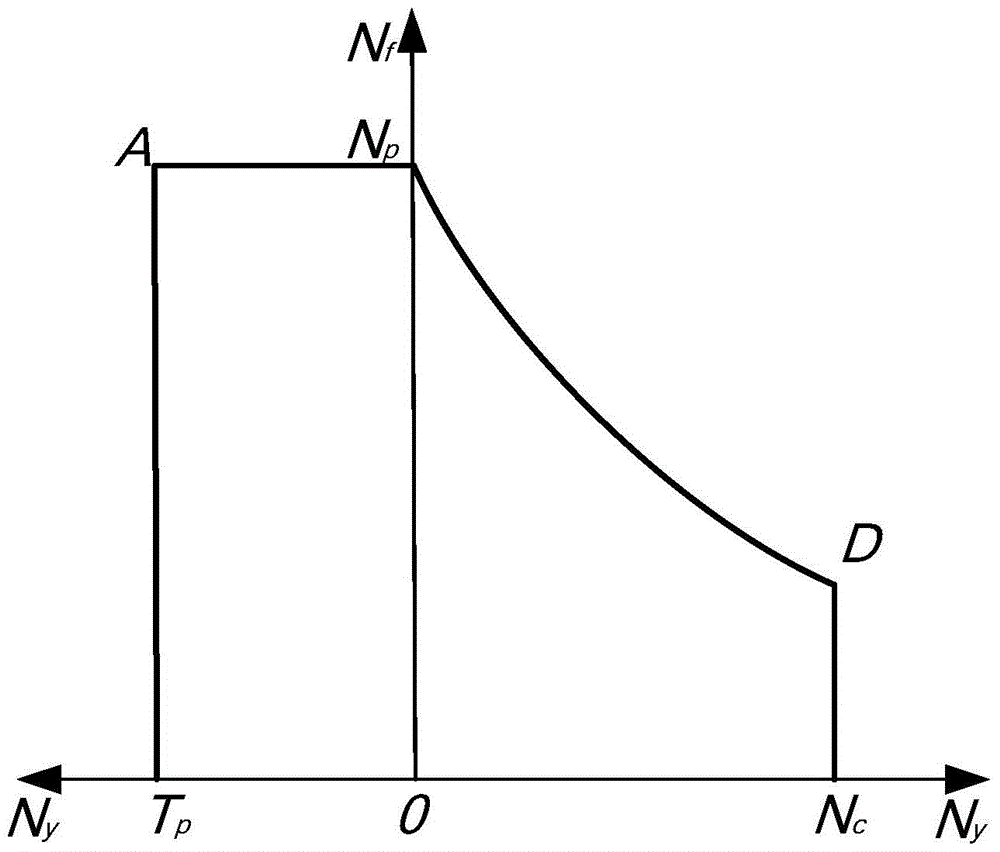

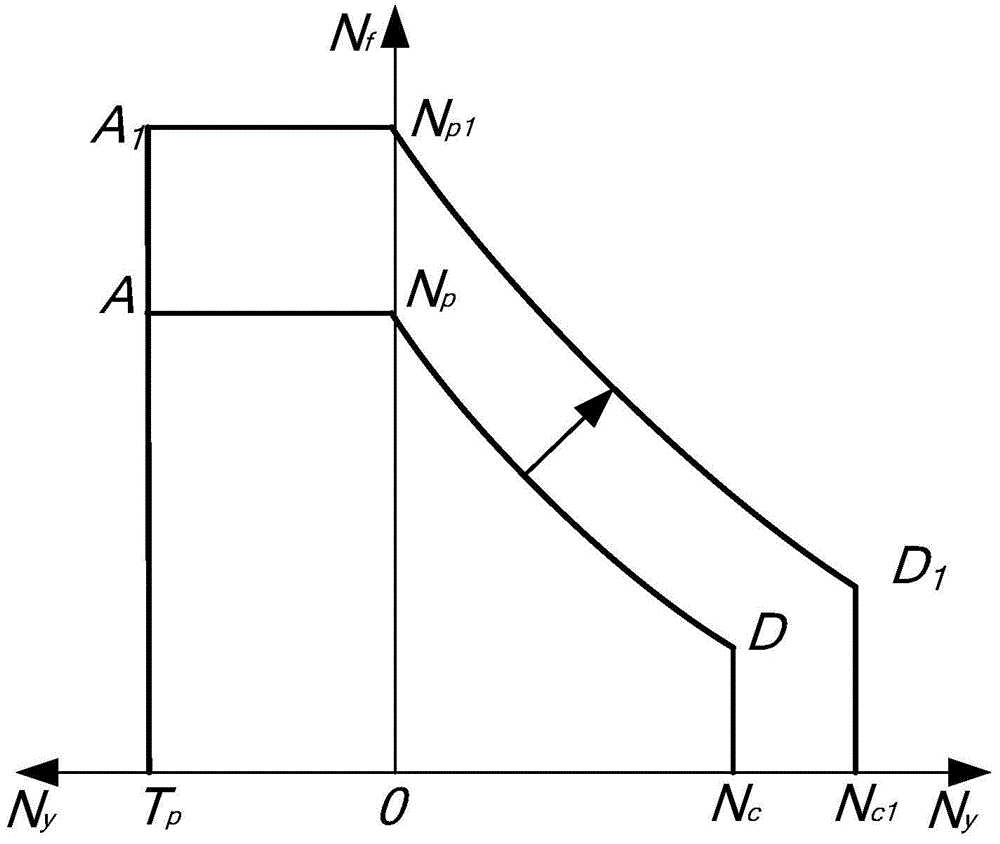

[0095] Step 1: Establish the reference life envelope of the corrosion fatigue key parts of the aircraft structure before life extension

[0096] The reference life envelope refers to the life envelope that meets the requirements of 99.9% reliability and 90% confidence level. In the actual use process, the life management of aircraft structures is carried out with the reference life envelope. The process of establishing the baseline life envelope is as follows:

[0097] (1) According to the service environment of the aircraft structure, the effective period T of the protective layer is determined through the accelerated environmental test in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com