Secondary battery, multifunctional diaphragm and preparation method

A secondary battery, multi-functional technology, applied in nickel batteries, alkaline batteries, battery pack parts and other directions, can solve the problems of inability to comprehensively suppress, fall off active substances, serious side reactions, etc. The effect of preventing excessive oxygen recombination of the negative electrode and improving the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

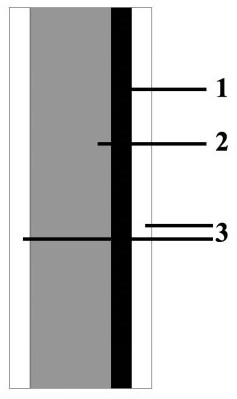

Method used

Image

Examples

Embodiment 1

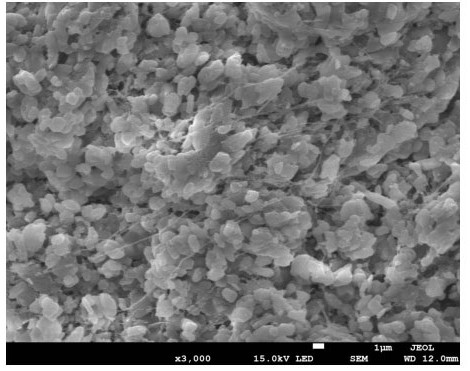

[0038] (1) Bi powder with a particle size of 100 nm, Zn powder with a particle size of 800 mesh, potassium polyacrylate particles, and gas-phase Al 2 o 3 , 60 wt.% PTFE aqueous solution was weighed and prepared at 7:5:3:3:2, and then other components except PTFE aqueous solution were placed in the mortar, and the powder was fully mixed by mechanical stirring and grinding. The components are evenly dispersed;

[0039] (2) Add PTFE aqueous solution and an appropriate amount of zinc-nickel battery electrolyte (30 wt.% KOH solution) to the mixed powder, and fully stir to form a soft and elastic powder; the added zinc-nickel battery electrolyte It can be followed: for every 0.7g of Bi powder in step (1), add 0.3 mL of electrolyte.

[0040](3) Use a roller press to press the dough into a film with a film thickness of 0.04 mm. After the film is formed, cut the film into a size of 100×80 mm for later use, or cut the size according to requirements; during the molding process, The me...

Embodiment 2

[0051] The difference between this embodiment and the above-mentioned embodiment 1 lies in: the ratio of each component in step (1).

[0052] (1) Bi powder with a particle size of 100 nm, Zn powder with a particle size of 800 mesh, potassium polyacrylate particles, and gas-phase Al 2 o 3 , 60 wt.% PTFE aqueous solution was weighed and prepared at 8:7:2:1:2, and then other components except PTFE aqueous solution were placed in the mortar, and the powder was fully mixed by mechanical stirring and grinding. The components are evenly dispersed;

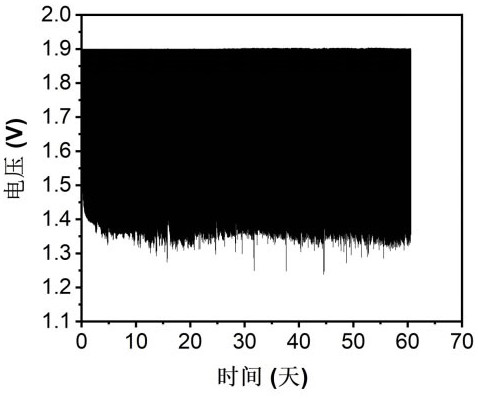

[0053] Subsequent steps (2) to (8) are consistent with those in Example 1. In the (5) step (5) of the zinc-nickel battery assembled with the diaphragm, the charge-discharge cycle test was carried out under the test conditions of a rate of 4C and a depth of discharge of 70%. After the cycle, the voltage dropped below 1.25 V, and the discharge voltage platform showed a steady downward trend, but there was no obvious short circuit phenome...

Embodiment 3

[0055] The difference between this embodiment and the above-mentioned embodiment 1 lies in: the ratio of each component in step (1).

[0056] (1) Bi powder with a particle size of 100 nm, Zn powder with a particle size of 800 mesh, potassium polyacrylate particles, and gas-phase Al 2 o 3 , 60 wt.% PTFE aqueous solution was weighed and prepared at 5:8:2:3:2, and then other components except PTFE aqueous solution were placed in the mortar, and the powder was fully mixed by mechanical stirring and grinding. The components are evenly dispersed;

[0057] Subsequent steps (2) to (8) are consistent with those in Example 1.

[0058] In the (5) step (5) of the zinc-nickel battery assembled with the diaphragm, the charge-discharge cycle test was carried out under the test conditions of a rate of 4C and a depth of discharge of 70%. After the cycle, the voltage dropped to around 1.20 V, and the discharge voltage plateau showed a steady downward trend, but there was no obvious short cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com